Controlling Fluid Flow with Ball Valves

Figure 1: Manual, pneumatic & electric ball valves

A ball valve is a type of quarter-turn valve with a hollow ball to control flow through it. A 90-degree turn of the valve will position the ball’s hole in line with the flow direction, and the reverse will completely shut-off the valve in the closed position. A stem is attached at the top of the ball which extends outwards through the stem’s seal to connect to a manual handle or a pneumatic/electric actuator. Ball valves are often used for ON/OFF operation but can also operate as a flow regulating valve.

Ball valves have three main types: standard port, full port, and v-port (for precise flow control). They are exceptionally durable and low cost. They maintain consistent performance after many cycles of operation, seal tightly, handle high pressure, and require little to no maintenance. The simple mechanism of a ball valve and its ease of operation and flexibility makes it popular in industrial applications with pressures up to 1,000 bar (14,500 psi) and temperature up to 400°C (752°F) . Read our ball valve article to learn more about the design and working of ball valves..

Flow regulation with ball valves

When the parameters (cost, maintenance, accuracy, etc.) of valves for flow control are placed side by side, ball valves are often suitable for most applications. It is quite common to use a ball valve for flow control because it is a cost-effective solution, and most processes don’t require precise accuracy of flow rates. The simplicity of ball valves and their robustness for flow control make them compatible with domestic, commercial, and industrial applications.

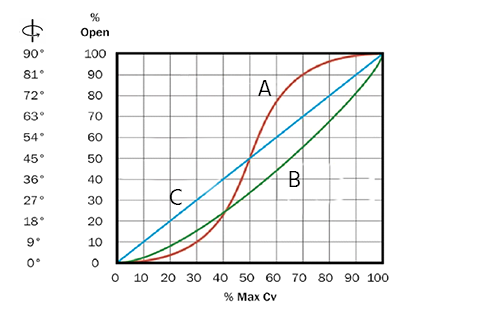

Figure 2: Flow characteristics of ball valve types: standard and full port ball valve (A), v-port ball valve (B), & linear curve (C)

Figure 2 shows different flow characteristics of ball valves based on their design. As you can see, the flow characteristics change depending on the design. A v-port ball valve has an equal percentage characteristics curve (Figure 2 labeled B), which increases flow control precision. An equal percentage characteristic curve approaches a linear curve, but is not quite a linear curve, as the max flow percentage slope increases as the valve opens.

When used in the right application, this characteristic of a v-port ball valve can be advantageous. For example, v-port ball valves are particularly useful where the rate of temperature change decreases with an increase in flow rate (i.e. heat transfer processes).

The advantages of ball valves as a flow control valve

Ball valves have a high turndown ratio (ratio of maximum flow to minimum flow). This means that a ball valve can regulate flow rate over a wide range. Valve rotation is consistent and steady without a jump effect (a slip in valve movement). This ensures that a proportional input signal from an actuator will deliver consistent flow rates at small valve openings. Ball valves are commonly used in control applications that require moderate pressure drops as the ball hole offers little flow restrictions, unlike most other valve types. Ball valves are useful in emergency flow regulation as the quarter-turn design ensures a fast actuating device. Learn more about the advantages of using a ball valve for flow control in our butterfly valve and ball valve comparison article.

Other advantages of ball valves as a flow control valve

- It can operate at high pressure and temperature.

- There is no leakage when fully shut.

- It has an excellent valve flow coefficient in a fully opended state. A full bore ball valve type has the flow characteristics of the pipe.

- There is self-cleaning of the sealing surface, which is why they can be used with lightly soiled media.

- It has a relatively smaller size and lighter weight when compared to other valve types with similar flow characteristics.

- Ball valves come in a wide range of connection types, such as flanged, union nut, threaded, etc.

Figure 3: A 24V DC 2-way stainless steel electrical ball valve

The disadvantages of ball valves as a flow control valve

When used as a modulating control valve, the full and standard port ball valves are great for applications such as filling a water tank and other flow control where linearly adjusted flow rates are not as important. The opening of the ball valves cylindrical hole creates an uneven distribution of flow for every degree of opening. Despite their versatility, ball valves are characterized by poor throttling, particularly at low flow rates. With a small valve opening, the high flow speed can wear down the valve parts. Ball valves are also not available for larger pipe diameters or are expensive at such sizes. Ball valves are primarily designed for on/off applications and may not provide precise flow regulation at high pressures. The sudden opening or closing of the ball can cause pressure spikes and flow fluctuations. In some cases, a ball valve may even self-close if used for flow control at high pressure that can cause a surge in pressure, damaging downstream equipment or injure nearby personnel.

What is a v-Port ball valve?

Figure 4: A v-port ball valve

A v-port ball valve is a type of ball valve where a v-shape characterizes the orifices opening for fluid flow, as seen in Figure 4. The V-shape design is typically on the ball but can be on the seat also. This v-shape allows the flow through the valve to be stable for control flow applications.

How does the v-port ball valve work for flow control?

As the valve rotates from a closed position, the small end of the ‘v’ opening allows fluid flow at high velocities. The flow rate through the valve continues to increase at a higher rate as the valve turns to the fully open state, in contrast to the full and standard port ball valve. Common angles of the ‘v’ are 15°, 30°, 45°, 60°, or 90°.

The v-port ball valve retains all the advantages of the standard port ball valves, but they also have better flow control abilities. This additional feature makes them commonly used in applications like: food processing, agriculture, chemical industry, waste processing, etc. The disadvantage of the v-port ball valve is the construction that requires extra measures to handle the higher velocity of flow.

To learn more about the selection of the correct ball valve for your operation, read our ball valve selection technical article!

Conclusion

The ball valve is a cost-effective solution for flow control applications where the precise regulation of flow rates is not a requirement. The v-port ball valve type offers additional precision for flow control while retaining the advantages of the full and standard port ball valves. When all the parameters of valve selection are considered, ball valves have several characteristics that make them a better general-purpose valve than other valve types.