Flow Meters For Beer Brewing

Figure 1: Flow meters help ensure the correct amount of beer enters each bottle.

A beer flow meter is an essential tool that brewers rely on to monitor and regulate the volume of beer as it moves through the brewing system. This instrument plays a critical role in various stages of production, including mashing, fermentation, and packaging. By providing accurate readings, flow meters help amateur and professional brewers achieve the desired balance of flavors and alcohol content in their beer, making them a staple in efficient brewing operations.

View our online selection of flow meters!

What is a flow meter?

A flow meter measures the volume or mass of a fluid (liquid, gas, or vapor) that flows past the meter over a specific period. There are various flow meters with different functions and working principles. They are effective in closed and open systems, such as piping and river channels.

Modern flow meters typically have electronic interfaces to display real-time digital readings. They can also connect directly with software systems for data analysis and record keeping. Traditional flow meters use analog methods to indicate the flow rate, for example, dials or a floating element within a transparent tube.

Why are flow meters used?

Flow meters are used simply to measure fluid flow; they serve several important purposes across various industries:

- Safety:Flow meters help maintain necessary flow rates for cooling in industrial processes.

- Leak detection:Flow meters measure flow rate at various points in the system. If the flow rate at any point is less than what is expected, a leak may be the cause.

- Monitoring:Operators can guarantee that systems are running both effectively and efficiently.

- Billing:Accurate flow measurements are necessary for billing purposes.

- Environmental compliance:Flow meters measure the amount of emissions and waste that enter the environment, ensuring levels are kept within regulation.

Flow meter applications in beer brewing

Flow meters are crucial in beer brewing, from small homebrew setups to large-scale industrial breweries. They are used to measure the fluid flow rate and ensure accuracy, efficiency, and consistency in various stages of brewing. Here's a comprehensive list of how flow meters might be used throughout a beer brewing system:

Small, homemade brewing systems

- Water treatment: Ensuring the correct proportions of water treatment additives by measuring the water flow rate entering the brewing system.

- Mashing: Monitoring water flow through the grain bed to maintain a consistent mash temperature and improve extraction efficiency.

- Sparging: Controlling the flow rate of sparge water to rinse sugars from the grain effectively without disturbing the grain bed.

- Boiling: Measuring wort flow into the boil kettle to determine the correct boil volume and hop usage.

- Chilling: Regulating wort flow through a cooling system, like a plate chiller, to quickly reduce the temperature before fermentation.

- Fermentation: Monitoring the addition of liquids, such as additional water or flavorings, to the fermenter at a controlled rate.

- Bottling/Kegging: Ensuring precise filling volumes when transferring beer to bottles or kegs, minimizing waste.

Large industrial brewing systems

- Water supply management: Large-scale breweries require massive amounts of water; flow meters help monitor water usage for sustainability and cost control.

- Mash transfer: Managing the flow rate during transfer between the mash tun and lauter tun to optimize sugar extraction and prevent channeling or compacting of the grain bed.

- Wort boiling: Controlling the flow rate of wort recirculation during boiling for even heat distribution and preventing caramelization or scorching.

- Cooling systems: In large breweries, flow meters are critical for managing the flow through plate or counterflow heat exchangers to achieve rapid cooling to fermentation temperatures.

- Fermentation control: Monitoring the addition of controlled ingredients during fermentation, including oxygen and nitrogen for aeration. A CO2 flow meter for beer helps with carbonation.

- Cleaning-In-Place (CIP) systems: Flow meters ensure that cleaning agents are delivered at proper rates to maintain hygiene standards without waste.

- Filtration and fining: Regulating the flow through filters or fining agents to clarify the beer without stripping flavor or over-processing.

- Blending: If blending different beer batches for consistency or creating new products, flow meters can ensure exact ratios.

- Packaging lines: Accurate filling of cans, bottles, or kegs is essential for consistency. Flow meters, such as beer tap flow meters and beer keg flow meters, prevent overfilling or underfilling, affecting product quality and legal compliance.

- Waste treatment: Managing wastewater flow to treatment facilities, where flow meters help monitor and reduce environmental impact.

- Utility monitoring: Flow meters track the usage of utilities like steam, gasses, and refrigerants that are crucial for various processes in the brewery.

Beer brewing flow meter requirements

Inline beer flow meters must possess certain qualities to function effectively in beer production. Understanding these requirements is crucial for anyone involved in brewing, from home enthusiasts to large-scale commercial producers. It ensures that one can make an informed decision when selecting a flow meter suited to their brewing operations.

- The sensor's measuring system is straightforward, with no components that obstruct flow or easily trap the substance being measured.

- Every flow meter component that contacts the media is made from materials that comply with food safety standards, such as those set by the FDA (United States Food and Drug Administration) and the EHEDG (European Hygienic Equipment Design Group). Learn more in our beer brewing system materials article.

- These components can endure sudden temperature changes and resist corrosion from cleaning agents like steam, alkaline water, and hydrogen peroxide.

- In filling operations, the sensor is required to react quickly and provide precise measurements.

- It is designed to function in cold (approximately 2 °C) and damp conditions.

Flow meter types for beer brewing

Surface acoustic wave (SAW) flow meters

Surface acoustic wave (SAW) flow meters use transducers to measure how sound waves move through a fluid, converting the result into a flow rate. This type of flow meter is non-invasive, highly accurate, and does not cause a significant pressure drop. Additionally, SAW flow meters have the following features that make them suitable for a beer brewing system:

- High accuracy

- No moving parts

- Fast response time

- Easy to clean

- Chemical resistance

- Temperature resistance

- Low maintenance

Despite all their advantages, SAW flow meters are only suitable for some applications. Specifically, they are not suitable for measuring gas and steam. Read our article on the Burkert 8098 SAW flow meter for an example to learn more about how these flow meters operate.

Figure 2: A stainless steel SAW flow meter

Electromagnetic flow meter

Electromagnetic flow meters, or mag meters, utilize Faraday's Law of Electromagnetic Induction to determine the flow rate of electrically conductive liquids within a pipe. They are composed of a non-magnetic, insulated pipe, with electrodes and coils arranged to create a magnetic field.

As the liquid passes through this field, it induces a voltage proportional to its velocity, which is captured by the electrodes and translated into a flow rate. These meters are non-obstructive, preserving the liquid's integrity, making them perfect for sensitive applications such as beer brewing.

Electromagnetic flow meters require the fluid to be electrically conductive. Because gas and steam are not conductive in the same way liquid is, these flow meters are unsuitable for measuring gas and steam flow rates.

Figure 3: An electromagnetic flow meter on a water pipe

Turbine flow meter

Turbine flow meters operate by using a rotor that spins in proportion to the flow rate of the fluid passing through it. The movement of the rotor is sensed electronically, and the data is then converted into a flow rate measurement. Despite having moving parts that contact the fluid, turbine flow meters do not have significant pressure drops.

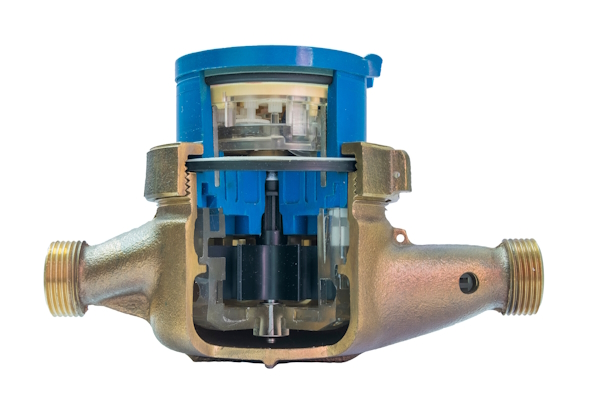

Figure 4: A crosssection of a turbine flow meter

Flow meter materials for beer brewing

Every component of a beer brewing system that contacts consumable media requires sanitary solutions. Concerning flow meters, beer brewing processes such mash transfer, wort boiling, and fermentation control require sanitary flow meters. The most common materials used for sanitary flow meters are stainless steel and plastics.

- Stainless steel:Stainless steel grades 316 and 304 are very common. They offer corrosion resistance and high resistance to temperature and pressure.

- Plastics:Plastics, such as PVC, are less expensive than stainless steel and also have excellent resistance to corrosion. However, PVC has much lower temperature and pressure resistance. For example, PVC begins to deform at temperatures above 60 °C.

For measuring flow rates of processes that do not contact consumable media, such as cooling processes, other materials (e.g., brass and cast iron) can be selected.