How Check Valves Work

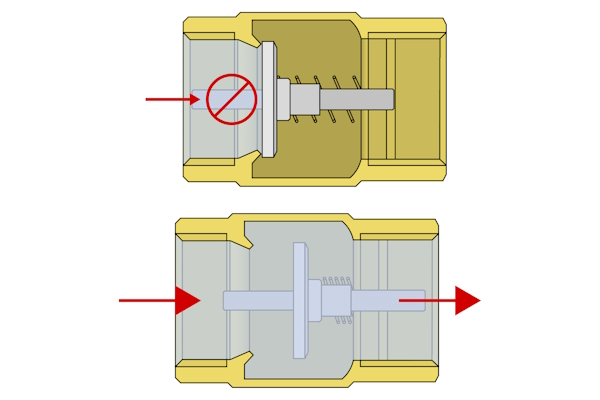

Figure 1: Check valve

A check valve allows liquid and air to flow in only one direction and prevents backflow. Backflow can lead to upstream media contamination, equipment damage, system inefficiency, increased maintenance costs, and regulatory compliance issues. For example, a sewer line will have a non-return valve to ensure that waste can leave a system (e.g., a residential plumbing system) but cannot re-enter.

Table of contents

- How does a check valve work?

- What is a check valve used for?

- Check valve types

- Check valve materials

- Selection criteria

- Check valve symbol

- FAQs

How does a check valve work?

Cracking pressure

A check valve requires a minimum pressure differential between the inlet and outlet to open, allowing media to flow through it. This minimum upstream pressure is called the check valve's cracking pressure or minimum pressure difference. Many check valves have a cracking pressure of 1 bar (14.5 psi) or lower. However, some have higher cracking pressures for applications with higher upstream pressure before the valve opens (e.g., hydraulic applications).

Closing

If the pressure differential falls below the cracking pressure (Figure 2) or there is back pressure (flow moving from the outlet to the inlet), the check valve will close. Check valves may have a gate, ball, diaphragm, or disc pressed against a valve seat to close the valve and block flow. Gravity or a spring can assist in the closing process.

Figure 2: The check valve closes when the differential pressure is below the valve's cracking pressure. It opens when the pressure rises above the cracking pressure.

Installation orientation

A one-way check valve allows flow in only one direction. Typically, an arrow on the valve's housing indicates the flow direction. If there is no arrow, use your finger or a narrow rod to push open the valve and understand its opening direction. If the valve is installed backward, the media cannot move through the system, and the resulting pressure build-up can cause damage.

What is a check valve used for?

Typical check valve applications are:

- To protect equipment downstream from backflow damage

- To prevent contamination due to reverse flow

- To prevent siphoning

- To keep a vacuum seal

Check valves are used in almost every industry. They are used on common household appliances, like dishwashers, washing machines, and wastewater lines. In industrial settings, they are used on boilers, furnaces, gas systems, pumping applications, vacuum systems, etc. They are also frequently used as aquarium check valves on water and CO2 lines.

Check valves for water

A water check valve is used in drinking water, wastewater, and irrigation applications. Plumbing check valves for drinking water applications ensure that no environmental media (outlet side of the valve) can enter the system and contaminate the clean drinking water.

For wastewater applications, they ensure that the wastewater cannot re-enter the system and cause an overflow or additional contamination.

A foot valve is often used for water pumping applications to ensure no debris enters the line and keeps internal pressure for priming purposes.

Sump pump check valves ensure that the discharged water does not return to the sump pump by gravity when the pump is turned off.

Check valve types

There are various types of check valves, each designed to suit specific applications.

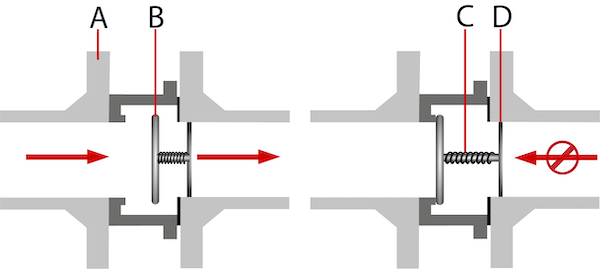

Inline spring-loaded check valves

Inline spring-loaded check valves use a spring mechanism to assist in closing. The spring ensures a quick response to changes in the flow direction, minimizing backflow risk. They are compact, can be installed in any orientation, and are suitable for systems with low-pressure differentials.

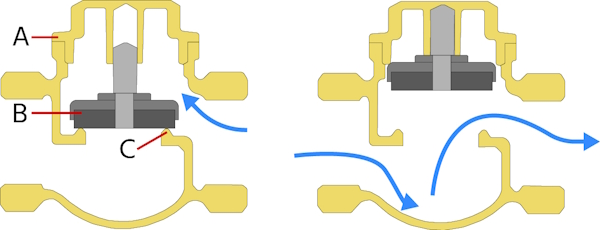

Figure 3: Spring-loaded in-line check valve open (left) and closed (right). The working components are the valve body (A), disc (B), spring (C), and guide (D).

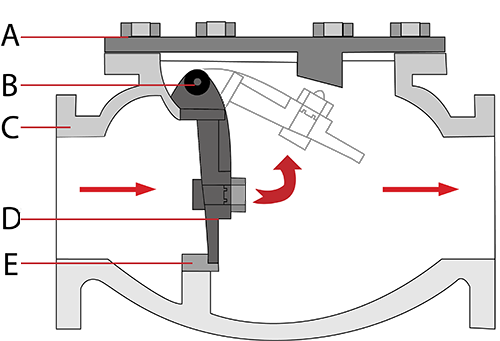

Swing check valves

Swing check valves feature a hinged disc that swings open with forward flow. They are simple to construct and suitable for large-diameter pipes. They offer minimal flow resistance and a low pressure drop when fully open. Swing check valves close via gravity, so they should only be installed horizontally.

Figure 4: Swing check valve. Bolted bonnet (A), hinge or trunnion (B), valve body (C), disc (D), seal (E).

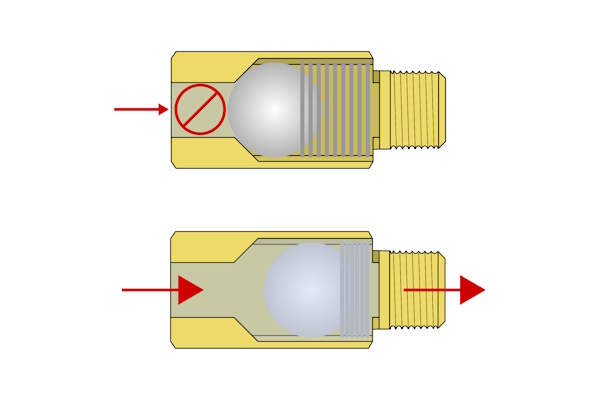

Ball check valves

Ball check valves utilize a ball as the closing mechanism. A common design has a ball with a slightly smaller diameter than the channel it rests in. When fluid enters the valve, it pushes the ball away from the seat and flows around it. This design has both spring-loaded and no-spring options.

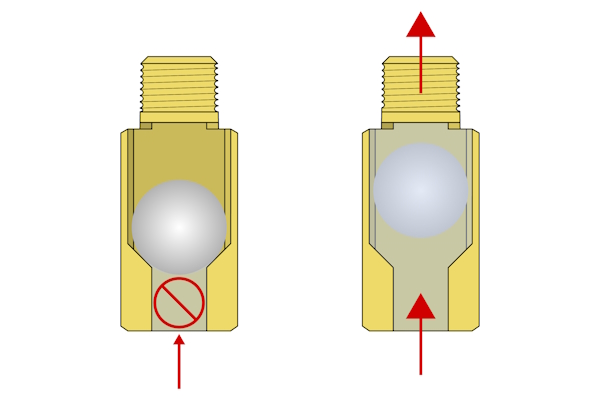

A spring-loaded ball check valve (Figure 5) can be installed in any orientation. A ball check valve without a spring must be installed vertically, with the port opposite the ball facing upwards. The primary benefit of a ball valve without a spring is one less part that can wear down or malfunction. Figure 6 shows that the externally threaded port is the side furthest from the ball.

Figure 5: A ball check valve with a spring. This valve can be installed in any orientation.

Figure 6: A ball check valve without a spring. This valve must be installed vertically and should only be used for upward flow.

Lift check valves

Lift check valves have a disc or piston that lifts vertically to allow flow. They require horizontal installation. They have minimal moving parts and are suitable for heavy-duty applications requiring frequent cycling. Furthermore, they are suitable for saturated steam up to 9 bar (130.5 psi).

Figure 7: Lift check valve design and function. Key components are body (A), disc (B), and seat (C). Upon backflow (left), the disc closes. During normal flow (right), the disc opens.

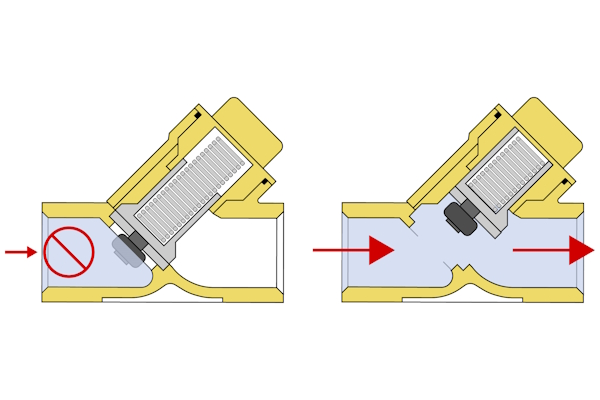

Y-shape check valves

Y-shape check valves have an angled flow path resembling the letter "Y." These valves reduce turbulence and pressure drop, having lower flow resistance than inline valves. Their design allows a user to open the valve and inspect internal parts without removing the valve from the line.

Figure 8: Spring-loaded Y check valves close when differential pressure is low (left) and open when upstream pressure overcomes the valve's cracking pressure. These valves offer a nearly straight-through flow.

Check valve materials

Stainless steel check valve

Stainless steel check valves are ideal for demanding environments because they resist corrosion, heat, and low temperatures. Due to their excellent mechanical properties, including high strength and durability, they have a long service life. These valves are well-suited for applications involving high temperatures and pressures, such as industrial processing, chemical plants, and oil and gas industries.

Stainless steel check valves are available in various grades - 304 and 316 are the most common. Grade 316 stainless steel offers enhanced resistance to chlorides and other corrosive substances. It is suitable for marine and coastal applications. While stainless steel check valves provide exceptional performance, they are less cost-effective than brass and plastic.

Key features

- Corrosion resistance: Excellent resistance to various corrosive media, including acids, alkalis, and chlorides. See our chemical resistance guide to learn more.

- Temperature tolerance: Capable of withstanding extreme temperatures, both high and low from -25 °C to 200 °C (-13 °F to 392 °F).

- Mechanical strength: High strength and durability, suitable for high-pressure applications up to 400 bar (5,800 psi).

- Versatility: Available in various grades to meet specific application requirements.

Suitable for

- Dilute and strong acids and bases

- Solvents

- Alcohols

- Combustible gasses

- Sea water

- Demineralized water

- Air

- Carbon dioxide

- Oil

- Fuel

- Lubricant

- Water

- Steam

Plastic check valve

Plastic check valves are frequently used in irrigation and water management systems. Three common body materials are PVC, PP, and PA. They are corrosion-resistant to most corrosive media, such as seawater, acids, bases, chloride solutions, and organic solvents. However, be careful when using aromatic and chlorinated hydrocarbons; double-check whether the valve material is resistant to the specific hydrocarbon.

Key features

- Corrosion resistance: Excellent resistance to a wide range of corrosive media, including seawater, acids, bases, and chloride solutions.

-

Temperature tolerance

- PVC: Capable of withstanding temperatures up to 60 °C (140 °F).

- PA: Capable of withstanding temperatures up to 90 °C (194 °F).

- PP: Capable of withstanding temperatures up to 80 °C (176 °F).

- Mechanical strength: Adequate strength for low to moderate pressure applications.

- Versatility: Suitable for a variety of water management and irrigation systems.

- Cost: More cost effective than brass and stainless steel.

Suitable for

- Alcohols

- Combustible gasses

- Sea water

- Air

- Oil

- Lubricant

- Water

Brass check valve

Brass check valves are excellent for air, water, oil, or fuel applications. However, they are not resistant to seawater or chlorinated water. Compared to stainless steel, brass is less resistant to heat and corrosion. It is typically used for lower-pressure applications.

Key features

- Corrosion resistance: Moderate resistance to corrosion, but not suitable for seawater or chlorinated water.

- Temperature tolerance: Limited temperature tolerance, generally suitable for low-temperature applications. Most brass valves operate up to 100 °C (212 °F) but some can operate at higher temperatures.

- Mechanical strength: Adequate strength for lower-pressure applications.

- Versatility: Suitable for a variety of applications involving air, water, oil, or fuel.

- Cost: More cost-effective than stainless steel.

Applications

- Alcohols

- Air

- Oil

- Fuel

- Lubricant

- Water

Selection criteria

Check valves have the following criteria to consider when selecting one for an application:

- Body material: Different materials have significantly different chemical and physical properties. Understand the differences to ensure the chosen material is suitable for your application. Read the section above for more information.

- Seal material: Common seal materials for check valves are EPDM, NBR, FKM, Teflon, FEP, and metal. Just like the body material, the seal material must be suitable for the application's media.

-

Line size for connection points:Select a valve with a connection size identical to the system you will install it into. If the valve is differently sized, you will need an adapter, which increases turbulence and pressure drop across the valve.

- Threaded check valves can be measured in inches or millimeters. Read our article on how to size a thread to learn more.

- Max pressure and cracking pressure requirement: Select a valve with a minimum necessary pressure lower than your application's normal operating pressure. This prevents the valve from chattering or open and closing too frequently. Also, ensure the valve's maximum pressure rating is higher than the highest pressure you expect your system to reach.

- Approvals: Some applications (e.g., residential and commercial water systems) may require valves with drinking water approvals (e.g., NSF ANSI 61).

- Kv: A valve's Kv indicates its flow rate under normal conditions. Use our Kv and Cv calculators to learn what Kv your valve should have. Oversizing or undersizing valves can cause significant issues.

- Installation orientation horizontal or vertical: Spring-loaded check valves can be installed in any orientation. Check valves that close via gravity should be installed horizontally. The one exception is ball check valves due to how they function (See ball check valve section above).

- External dimensions: Double check that the check valve is appropriately sized to fit where it needs to fit.

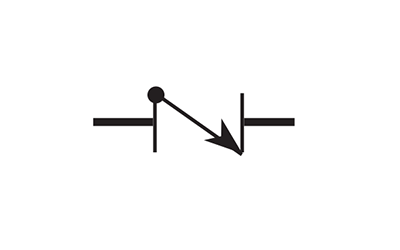

Check valve symbol

The P&ID symbol for check valves is shown in Figure 9.

Figure 9: The check valve P&ID symbol points in the orientation that it allows the flow with a vertical line showing it doesn’t allow backflow.

Learn about other types of valves in our valve fundamentals article.

FAQs

What is a check valve?

A check valve is a one way valve that passes fluid in one direction but prevents any flow in the opposite direction.

What does a check valve do?

The main purpose of a check valve in a system is to prevent backflow, which could damage equipment or contaminate media upstream.

What are common check valve problems?

Common check valve problems are noise, water hammer, vibration, reverse flow, sticking, leakage, and component wear/damage.

Will a check valve stop water hammer?

A check valve can prevent water hammer if it is fast-acting like a spring-actuated check valve. This prevents pressure surges, which create shock waves throughout the media.