Plumbing Check Valve

Figure 1: PVC check valve for plumbing

Plumbing check valves allow water to flow in only one direction and stop it from flowing backward. This prevents contamination, pump damage, and pressure loss in residential, commercial, and municipal systems. They are essential in applications like sump pumps, water heaters, irrigation systems, and main water supply lines, where backflow can cause flooding or introduce pollutants into clean water.

Table of contents

- Different types of check valves in plumbing

- Plumbing check valve materials

- How to select the pressure rating for a plumbing check valve

- Plumbing check valve applications

- FAQs

View our online selection of check valves!

Different types of check valves in plumbing

Table 1: Plumbing check valve types

| Valve type | Best for | Installation orientation | Advantages |

| Spring-loaded(Inline or Y-type) | Standard/High-Pressure water lines, hot water recirculation, booster pumps, fire sprinklers, commercial plumbing. | Any orientation | Fast and silent. Y-type offers easy maintenance access. |

| Ball check valve | Small systems, residential appliances, garden hoses, small irrigation, booster pumps. | Spring-Loaded: Either way. Gravity-Operated: Vertically, with outer thread facing upwards. | Requires minimum maintenance, compact size. |

| Swing check valve | High-volume horizontal lines, pumping stations (sewage), municipal water mains, slurries. | Horizontal water lines (implied). | Minimal pressure drop, performs well with slurries and suspended particulates, available in large sizes. |

Plumbing check valve materials

Ensure the material used for the check valve can withstand the water's temperature range, potential additives (like chlorine), and pressure conditions without degrading. For more information, refer to our chemical resistance guide.

Table 1: Common check valve housing materials used in plumbing

| Material | Main feature | Best for | Avoid |

| Stainless steel | Durable at high temperature and pressure, corrosion-resistant | Sewage disposal, booster pumps, sump pumps with dirty water | Cost-sensitive plumbing where corrosion isn't an issue |

| Brass | Moderate temperate and pressure tolerance, suitable for general-purpose applications | Main water supply, washing machines, clean water sump pumps | Sewage systems, high-chlorine environments |

| PVC | Lightweight, cost-effective, resistant to many chemicals | Irrigation systems, low-pressure applications | Hot water lines, high-pressure systems, areas with temperature swings, direct UV |

Seal materials like NBR (Nitrile), FKM (Viton), and EPDM are commonly used. Read our check valve material article for more guidance on selecting the appropriate material for check valves.

How to select the pressure rating for a plumbing check valve

-

Cracking pressure:Choose a valve with the right cracking pressure so it opens under normal system flow.

- If it's too high, the valve may not open, causing flow restrictions.

- Maximum pressure: Choosing a valve with the right maximum pressure rating ensures it can withstand the highest system pressures and sudden surges.

Example

Consider a residential water supply system with an operating pressure typically ranging from 2.8 to 4 bar (40 to 60 psi).

- Cracking pressure: A suitable check valve should have a cracking pressure low enough to minimize flow restriction and pressure drop, typically around 0.07 to 0.14 bar (1 to 2 psi). This ensures the valve opens easily under normal conditions.

- Maximum pressure rating: Pressure spikes from water hammer can significantly exceed normal operating pressures. For a 4-bar system, it's advisable to use a check valve rated for about 2-3 times the normal operating pressure, such as 8-12 bar (120-180 psi). This provides an adequate safety margin.

Plumbing check valve applications

A plumbing check valve operates in:

- Municipal water inlet

- Water heaters

- Appliances (e.g., dishwashers and washing machines)

- Pump systems (e.g., booster pumps and sump pumps)

- Irrigation systems

Municipal water inlet

Check valves prevent backflow from a building into the municipal water supply, protecting against contamination and ensuring water quality. They are typically installed downstream of the water meter, where the supply line enters the building.

.jpg)

Figure 5: A typical water service line setup from the water main to a building: municipal water supply (A), water shut-off valve (B), pressure reducing valve (C), water meter (D), isolation valve (E), check valve (F), and pipes to individual appliances (G)

Water heaters

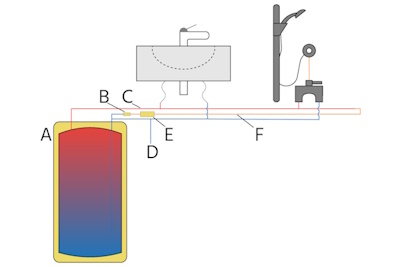

In water heater systems, check valves prevent the backflow of hot water into the cold water supply line. This maintains system efficiency and ensures hot water availability. They also help manage thermal expansion by maintaining pressure and preventing backflow.

Figure 6: Hot water recirculation system example: storage water heater (A), check valve to prevent backflow (B), insulated supply pipe for heat retention (C), cold water supply line (D), recirculation circulator for continuous flow (E), and insulated return pipe to maintain temperature (F).

Washing machines and dishwashers

Check valves are installed in the water supply lines to washing machines and dishwashers. They prevent dirty or soapy water from backflowing into the household water supply, avoiding contamination and potential flooding.

.jpg)

Figure 7: Hot (red) and cold (blue) water lines connect to a washing machine through check valves

Booster pumps

Check valves in booster pump systems prevent pressurized water from escaping backward when the pump turns off. This ensures the pump does not run constantly and maintains adequate water pressure throughout the building.

.jpg)

Figure 8: Booster pump system: Low-pressure well (A), water line to booster pump (B), cutoff valve (C), check valve (D), route of old water line (E), booster pump (F), new pipe (G), old water line under high pressure (H), and pressure tank (I)

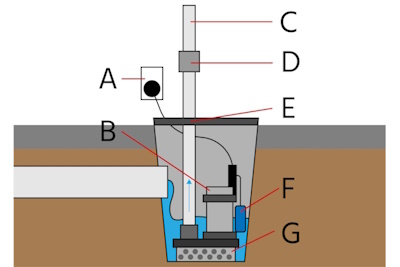

Sump pumps and sewage ejector systems

Check valves in these systems are installed in the discharge line to prevent water or sewage from flowing back into the pit, reducing pump cycling and wear, and preventing flooding and contamination during failures or power outages. Read our sump pump check valve article for more details.

Figure 10: Sump pump check valve vertical installation: electric power (A), sump pump motor (B), discharge pipe (C), check valve (D), sump basin cover (E), float switch (F), and screen (G).

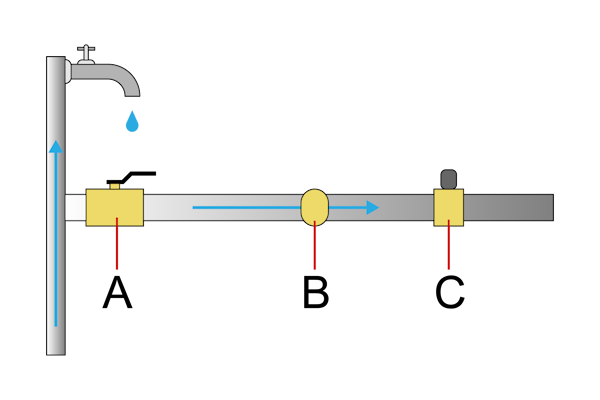

Irrigation and lawn sprinkler systems

Check valves in irrigation systems prevent water from flowing back into the main supply, avoiding contamination with fertilizers, pesticides, or other chemicals used in the system.

Figure 9: An automated water control system with an isolation valve (A), check valve (B), and master solenoid valve. The check valve allows water to flow forward when the master solenoid valve opens and prevents backflow into the main supply line when it closes.

FAQs

Do you need a check valve for kitchen sink drain?

No, a check valve is not typically needed for a kitchen sink drain. The drainage system relies on gravity to carry wastewater away, and a P-trap prevents sewer gases from entering the home.

Where should a plumbing check valve be installed?

Install on the discharge side of pumps or before sensitive equipment to prevent backflow.

What’s the difference between a backflow preventer and a check valve?

Check valves allow flow in one direction only; backflow preventers also protect against contamination under varying pressures.

Can I use PVC check valves for hot water?

PVC is not suitable for hot water above 60 𐩑C (140 𐩑F).

What if the check valve flow direction is wrong?

The valve will block flow, may leak, or be damaged; always follow the marked flow direction.

What if a check valve fails?

Backflow may occur, causing system contamination, pressure loss, or damage to pumps and equipment.