The Difference Between a Hydraulic and Pneumatic Cylinder

Figure 1: A hydraulic cylinder (left) and pneumatic cylinder (right).

Hydraulic and pneumatic cylinders are essential components in various industrial applications. Both types of cylinders convert energy into mechanical force, but they operate differently and suit different tasks. In general, hydraulic cylinders are for higher force applications and pneumatic cylinders are for faster applications. Understanding the differences between hydraulic and pneumatic cylinders can help select the right one for an application's specific needs.

Table of contents

- What is a hydraulic cylinder?

- What is a pneumatic cylinder?

- Hydraulic cylinders vs pneumatic cylinders

- Selecting the right cylinder for an application

View our online selection of pneumatic cylinders!

What is a hydraulic cylinder?

A hydraulic cylinder is a device that converts hydraulic energy into mechanical energy. It works based on Pascal's Law, which says that pressure on a confined fluid spreads equally in all directions. When the pump sends hydraulic fluid into the cylinder, it creates pressure that moves the piston. This movement generates linear force, which can lift, push, or pull loads.

Design

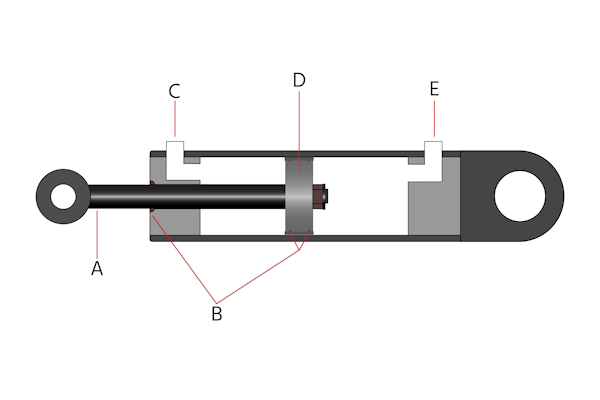

As seen in Figure 2, the key components of a hydraulic cylinder include:

- Piston rod (A): The piston rod is a cylinder that connects the hydraulic cylinder to the machine part it moves, passing on the force from the hydraulic fluid.

- Seals (B): Seals, including piston rod seals (left) and piston seals (B), stop hydraulic fluid from leaking out of the cylinder and keep the pressure inside for efficient operation.

- Retract flow port (C): The retract flow port is where hydraulic fluid enters the cylinder, making the piston retract and the piston rod move back into the cylinder.

- Piston (D): The piston is a solid disc inside the cylinder that splits it into two chambers and moves back and forth with hydraulic pressure to create straight-line motion.

- Extend flow port (E): The extend flow port is where hydraulic fluid enters the cylinder, making the piston extend and the piston rod move out of the cylinder.

Note: These components describe a typical double-acting hydraulic cylinder. A single-acting hydraulic cylinder uses a spring to return the piston to its original position.

Figure 2: A hydraulic cylinder's key components: piston rod (A), rod and piston seals (B), retract flow port (C), piston (D), and extend flow port (E).

What is a pneumatic cylinder?

A pneumatic cylinder is an actuator that converts compressed air energy into mechanical energy. It operates on the principle of using pressurized air to create motion. When compressed air enters the cylinder, it pushes the piston, causing it to move. This movement generates linear force, which can perform various tasks such as pushing, pulling, lifting, or lowering.

Design

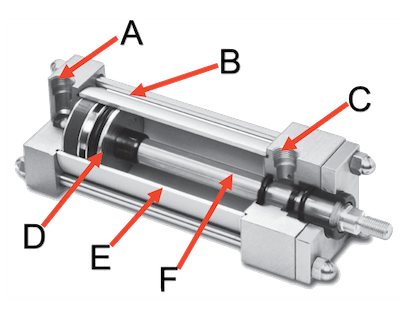

As seen in Figure 3, the key components of a pneumatic cylinder include:

- Cap-end port (A): The cap-end port is where compressed air enters the cylinder, making the piston move towards the rod end.

- Tie rod (B): The tie rod is a part that holds the end caps and barrel together, keeping the pneumatic cylinder strong and aligned.

- Rod-end port (C): The rod-end port is where compressed air enters the cylinder, making the piston move towards the cap end.

- Piston (D): The piston is a movable part inside the cylinder that splits it into two chambers and turns the pressure of compressed air into straight-line motion.

- Barrel (E): The barrel is the main body of the pneumatic cylinder that holds the piston and creates a sealed space for compressed air to move the piston.

- Piston rod (F): The piston rod is a cylinder that extends from the piston and transfers the piston’s linear motion to external machinery or a load.

Note: These components describe a typical double-acting pneumatic cylinder. A single-acting pneumatic cylinder uses a spring to return the piston to its original position.

Figure 3: Pneumatic cylinder parts: cap-end port (A), tie rod (B), rod-end port (C), piston (D), barrel (E), and piston rod (F).

Hydraulic cylinders vs pneumatic cylinders

Table 1 overviews the key differences between hydraulic and pneumatic cylinders.

Table 1: Aspects of hydraulic and pneumatic cylinders

| Aspect | Hydraulic cylinders | Pneumatic cylinders |

| Operating medium | Liquid (typically oil) | Compressed air (gas) |

| Pressure range | 70 to 350 bar (1,000 to 5,000 psi) or higher | 5.5 to 8.3 bar (80 to 120 psi) |

| Force generation | Higher force due to higher operating pressures | Lower force due to lower operating pressures |

| Applications | Heavy lifting, precise control, sustained force | Faster and lighter movements, quick cycling |

| Movement characteristics | Smooth and precise movements due to incompressible fluid | Faster and more responsive movements due to compressible air |

| Control precision | Higher precision due to incompressible nature of hydraulic fluid | Less precise control due to compressibility of air |

| Construction materials | Robust materials such as steel or heavy-duty alloys | Lighter materials such as aluminum or composite materials |

| Component design | Designed to handle high pressures and heavy loads, precise machining, tight tolerances | Focus on speed and ease of maintenance, components designed for quick replacement |

| Cost | Generally more expensive due to robust construction and precise machining | Generally less expensive due to lighter materials and simpler construction |

Selecting the right cylinder for an application

Choosing between a hydraulic and pneumatic cylinder depends on several factors, including the required force, speed, precision, and environmental considerations. Evaluating these factors will help you determine the most suitable cylinder for your specific application.

When selecting the right cylinder for your application, consider the following factors:

- Force requirements: Determine the amount of force needed for the application. Hydraulic cylinders are better for high-force requirements, while pneumatic cylinders are suitable for lighter tasks.

- Speed and response time: Evaluate the speed and response time needed. Pneumatic cylinders offer faster movement because air is not as dense as hydraulic fluids, whereas hydraulic cylinders provide more controlled and steady motion.

- Precision and control: Consider the level of precision and control required. Hydraulic cylinders offer more precise control due to the incompressible nature of hydraulic fluid.

- Environmental conditions: Assess the operating environment. Pneumatic cylinders are preferable in clean environments where contamination from hydraulic fluid is a concern.

- Cost and maintenance: Factor in the initial cost and ongoing maintenance. Pneumatic systems are usually cheaper and easier to maintain, while hydraulic systems can be more expensive initially and need more maintenance.

Application-specific recommendations

Use the following application recommendations to help guide in the selection process:

- Heavy-duty applications: For tasks like construction equipment, manufacturing machinery, and automotive systems, experts recommend hydraulic cylinders because they provide high force and are durable.

- Hydraulic tools: Hydraulic cylinders are used in tools such as hydraulic pullers, hydraulic spreaders, and hydraulic jacks.

- High-speed operations: For automation, robotics, and packaging machinery where speed and quick cycling are important, pneumatic cylinders are the better choice.

- Precision tasks: In applications needing precise control and smooth movements, like in aerospace and some manufacturing processes, hydraulic cylinders are more suitable.

- Clean environments: For medical equipment and food processing, where minimizing contamination is crucial, experts prefer pneumatic cylinders due to their use of clean compressed air.

- Cost-sensitive projects: For applications with budget constraints, pneumatic cylinders offer a cost-effective solution with lower initial costs and simpler maintenance.

- Yacht systems: Learn about how pneumatic systems are used in yacht systems by reading our Mason Marine case study.

Figure 4: Hydraulic cylinders used in heavy agricultural equipment

FAQs

What is the difference between hydraulic and pneumatic cylinders?

Hydraulic cylinders use fluid to generate force, while pneumatic cylinders use compressed air.

How do hydraulic cylinders compare to pneumatic cylinders in terms of force?

Hydraulic cylinders provide higher force due to incompressible fluid, while pneumatic cylinders offer less force with compressed air.

What are the speed differences between hydraulic and pneumatic cylinders?

Pneumatic cylinders generally operate faster than hydraulic cylinders due to the quick response of compressed air.

Which applications are best suited for hydraulic vs pneumatic cylinders?

Hydraulic cylinders are ideal for high-force tasks, while pneumatic cylinders are better for fast, low-force applications.