Festo Pneumatic Mufflers & Muffler Throttle Valves

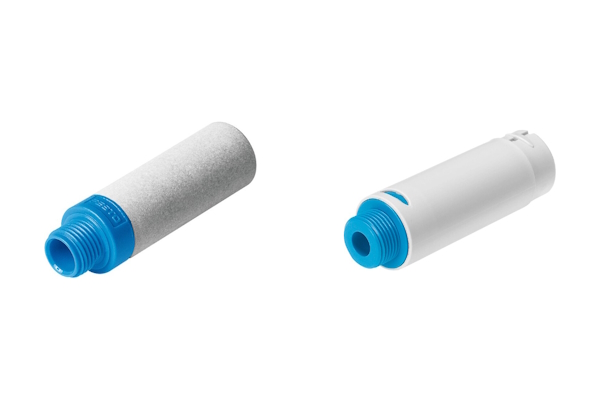

Figure 1: Festo's pneumatic mufflers and pneumatic muffler throttle valves

Festo pneumatic mufflers and pneumatic muffler throttle valves significantly reduce exhaust noise and regulate airflow to enhance system efficiency and performance. Festo offers a diverse range of standard pneumatic mufflers, high-performance mufflers, pneumatic filter mufflers, and pneumatic muffler throttle valves. This article provides an overview of Festo's pneumatic muffler products to help readers understand their similarities and differences and choose the best device for the application.

Table of contents

- Standard mufflers

- High-performance mufflers

- Pneumatic filter mufflers

- Pneumatic muffler throttle valves

- FAQs

Standard mufflers

Festo's pneumatic muffler range is designed to cater to various operational needs, ensuring users can find the right solution for their specific applications. Table 1 provides valuable insights into four different series of Festo pneumatic mufflers: the U series, UC series, AMTE series, and UOS-1 series.

- Noise reduction: The noise reduction levels, measured in decibels (dB(A)), indicate how effectively each muffler can lower the sound produced by the exhaust air, with lower values representing better noise attenuation.

- Flow rate: Flow rate, measured in liters per minute (l/min), shows the volume of air that can pass through the muffler, which is crucial for maintaining system efficiency and performance.

- Material composition: Material composition details the construction materials used in each series, such as sintered metal, polymers, brass, and bronze, which affect durability, resistance to environmental conditions, and compatibility with other system components.

Read our article on pneumatic muffler working principles to learn more about how they work.

Table 1: Festo's standard pneumatic mufflers

| Series | Noise reduction (dB(A)) | Flow rate (l/min) | Material composition | Operating conditions (pressure/temperature) | Note(s) |

|---|---|---|---|---|---|

| FESTO U series | <65 to <84 | 80 to 19,900 | Sintered metal, polymer, die-cast aluminum | 0 to 10 bar / -10°C to +70°C | - |

| FESTO UC series | <58 to <68 | 170 to 3,200 | PE (polyethylene) for both threaded plug and silencer insert | 0 to 10 bar / -10°C to +70°C | Compatible with QS push-in connectors and solenoid valves |

| FESTO AMTE series | <55 to <95 | 91 to 17,235 | Brass for screwed plug, bronze for cushioning insert | 0 to 10 bar / -40°C to +80°C | Come in short and long designs to meet various noise reduction and flow rate needs |

| FESTO UOS-1 series | - | - | POM (polyoxymethylene) housing, wrought aluminum alloy sleeve, PE silencer insert | 0 to 10 bar / -10°C to +50°C | Designed for use with MS6-SV pressure build-up exhaust valve |

Figure 2: Festo's standard pneumatic muffler series: U (top left), UC (top right), AMTE (bottom left), and UOS-1 (bottom right)

High-performance mufflers

Festo's high-performance pneumatic mufflers work particularly with VN-T2 and VN-T3 vacuum generators. Table 2 outlines three specific types: the UO series pneumatic mufflers, the UOM series pneumatic mufflers, and the UOMS series pneumatic silencer extensions. Each type is crafted from high-quality materials, such as polyethylene, polyacetal, wrought aluminum alloy, and polyurethane foam, contributing to their durability and effective noise attenuation. The UO and UOM series are designed to be easily screwed into place, while the UOMS series offers engaging mounting for added convenience. By integrating these high-performance mufflers with VN-T2 and VN-T3 vacuum generators, users can achieve optimal noise reduction and maintain the efficiency of their pneumatic systems.

Table 2: Festo's high-performance pneumatic mufflers for vacuum generators

| Feature | FESTO UO series pneumatic mufflers | FESTO UOM series pneumatic mufflers | FESTO UOMS series pneumatic silencer extensions |

|---|---|---|---|

| Purpose | Use with vacuum generators VN-T2/T3 |

||

| Material composition | Polyethylene threaded plug and silencer insert | Polyacetal housing and threaded plug, wrought aluminum alloy inner pipe, polyurethane foam silencer insert |

|

| Operating conditions | 0 to 8 bar, -10°C to +60°C |

||

| Mounting | Screw-in |

Engaging | |

Figure 3: Festo's high-performance pneumatic muffler series: UO (left) and UOM and UOMS (right).

Pneumatic filter mufflers

A pneumatic filter muffler, such as Festo's LFU series, serves a dual purpose in pneumatic systems: it reduces the noise generated by exhaust air and filters out contaminants to protect the system's components. Table 3 highlights several key features of the LFU pneumatic filter muffler. With a filtration efficiency exceeding 99.99%, it effectively removes oil and other contaminants from the exhaust air, ensuring cleaner operation and prolonging the system's lifespan. Festo also offers the LFPU filter cartridge as an essential replacement part for the pneumatic filter muffler.

Table 3: Festo's LFU pneumatic filter muffler

| Feature | Description |

|---|---|

| High filtration efficiency | >99.99% removal of oil and contaminants |

| Noise reduction | Reduces exhaust noise by 40 dB(A) |

| Condensate collection | Collected in the lower plastic bowl, manually drained |

| Material composition | Polypropylene (PP) housing |

| Operating conditions | Suitable for 0 to 16 bar pressure, -10°C to +60°C temperature |

| Mounting | Designed for vertical mounting with a tolerance of ±5° |

Figure 4: Festo's LFU series pneumatic filter muffler

Pneumatic muffler throttle valves

A pneumatic muffler throttle valve both reduces exhaust noise and regulates airflow, thereby enhancing system efficiency and performance. Table 4 overviews three series of Festo's pneumatic muffler throttle valves: the GRU, GRE, and VFFK series. Each series features different adjustable components, such as slotted head screws or knurled screws, which allow for precise control over airflow. The material composition varies across the series, indicating the durability and suitability for different applications. The screw-in mounting method facilitates easy installation, while the standard nominal flow rate, ranging from 80 to 8,000 liters per minute, provides insight into the capacity and suitability of each valve for different flow requirements.

Table 4: Festo's pneumatic muffler throttle valves

| Feature/Specification | FESTO GRU series muffler throttle valves | FESTO GRE series muffler throttle valves | FESTO VFFK series muffler throttle valves |

|---|---|---|---|

| Adjustable component | Slotted head screw |

Knurled screw | |

| Material composition | PA (polyamide) for adjusting screw, die-cast aluminum for housing and threaded plug | Brass for adjusting screw, wrought aluminum alloy for threaded plug, NBR seals | Nickel-plated brass for threaded plug and regulating screw, aluminum for knurled nut, PE for silencer insert |

| Operating conditions | 0 to 10 bar, -10°C to 70°C |

0 to 10 bar, 0°C to 60°C | |

| Mounting | Screw-in mounting |

||

| Standard nominal flow rate | 1,000 to 8,000 l/min | 520 to 3,600 l/min | 80 to 420 l/min |

Figure 5: Festo's pneumatic muffler throttle valves series: GRU (left), GRE (middle), and VFFK (right).

FAQs

What is a Festo pneumatic muffler?

A Festo pneumatic muffler reduces exhaust noise and regulates airflow in pneumatic systems, enhancing efficiency and performance.

How does a Festo pneumatic muffler throttle valve work?

A Festo pneumatic muffler throttle valve combines noise reduction with precise airflow control, optimizing pneumatic system performance.

What types of pneumatic mufflers does Festo offer?

Festo offers standard pneumatic mufflers, high-performance mufflers, pneumatic filter mufflers, and pneumatic muffler throttle valves.

Why choose Festo pneumatic mufflers for your system?

Festo pneumatic mufflers significantly reduce noise and improve airflow regulation, enhancing overall system efficiency and performance.