Festo VHEF manually actuated valve

Figure 1: Festo VHEF selector valve

Festo's VHEF valve is a versatile, manually operated pneumatic valve designed to control the flow of compressed air in various industrial applications. By simply moving the lever, operators can easily control the air flow, making it straightforward to use. This valve is available with different lever types, including pushbutton, toggle lever, finger lever, hand lever, and selector switch, each suited for specific operational needs. This valve is characterized by its compact and lightweight design, making it suitable for installations where space and weight are critical considerations.

Key features

- Multiple configurations: Offers 3/2-way, 5/2-way, and 5/3-way functions with flow rates up to 1200 liters per minute, handling a wide range of pneumatic tasks efficiently.

- Ease of use: Designed with minimal actuating forces for straightforward manual operation, reducing operator fatigue.

- Flexibility: Configurable pneumatic working ports to meet specific application requirements. The 3/2-way valve can be used in normally closed (NC) or normally open (NO) positions. The valve supports reverse operation for easy system reconfiguration.

- Durable construction: Features a durable metal housing and polymer cover, suitable for vacuum applications and operating within a pressure range from vacuum to 10 bar.

- Mounting options: Can be mounted using standard mounting holes and is compatible with front panel installations (except for the finger lever variant), ensuring easy integration into various systems.

Common applications

- Control of pneumatic cylinders: Used in industrial automation to control single-acting and double-acting cylinders. VHEF valves manage the extension and retraction of cylinders, ensuring precise movement in automated machinery.

- Conveyor systems: Utilized in material handling to start and stop conveyor belts. 3/2-way valves in normally closed positions control the flow of air to move or halt conveyor belts, optimizing material transport.

- Filling and sealing machines: Essential in the packaging industry for managing filling, sealing, and cutting operations. 5/2-way valves control the sequence of operations, ensuring efficient and accurate packaging processes.

- Assembly lines: Critical in the automotive industry for controlling pneumatic tools and actuators. VHEF valves manage various stages of assembly, such as welding, painting, and part assembly, enhancing production efficiency.

- Pneumatic braking systems: Used in safety-critical applications to release pressure in braking systems. 5/3-way valves with mid-position exhausted functions ensure safe pressure release, preventing accidents and maintaining system integrity.

Festo VHEF valve actuation lever types

Festo's VHEF series of manually actuated valves are available with various actuation lever types, each suited for specific operational needs.

Table 1: Festo VHEF valve actuation lever types

| Actuation lever type | Features | Diagram |

| Finger lever valve (L) | Slim design, easy to actuate with a finger, through-hole mounting |  |

| Hand lever valve, top and sideways (H/HS) | Suitable for demanding applications, the hand lever valve handles higher actuating forces and offers both lateral and top mounting configurations. Its robust construction ensures long-term reliability in harsh environments. |  |

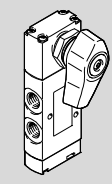

| Selector valve (E/ES) | Excels in applications requiring multiple switching positions, making it suitable for complex control tasks. Its side mounting design is perfect for constrained spaces. |  |

| Pushbutton valve (P) | Compact and lightweight, the pushbutton valve is ideal for space-limited applications. It requires minimal actuating force and offers versatile mounting options, including front panel and through-hole mounting. |  |

| Toggle lever valve (V) | Provides a clear visual indication of the valve position, robust design, front panel mounting |  |

Festo VHEF valve functions

3/2-way valve

- Normally closed (NC) or normally open (NO): These valves can be normally closed or normally open, providing flexibility depending on the application requirements. In the normally closed position, the valve blocks the flow of air until actuated, while in the normally open position, it allows air to flow until actuated to close.

- Double solenoid/Bistable: They are bistable, meaning they have two stable positions and the valve remains in its last actuated position until manually switched to the other position.

- Monostable (non detenting): These valves return to their default position when not actuated. They are typically used in applications where a default state is required for safety or operational reasons during power loss.

5/2-way valve

A 5/2-way valve has five ports and two positions. It is commonly used for controlling double-acting cylinders and can be configured as: a single (monostable) or double (bistable) solenoid. The monostable configuration is ideal for emergency stop functions where a default position is necessary, while the bistable one is suitable for automated machinery requiring the valve to hold its position.

5/3-way valve

A 5/3-way valve has five ports and three positions, providing more control options:

- Mid-position closed: The term "mid-position" refers to the neutral or center position of the valve. In the middle position, all ports are closed, blocking any air flow. This configuration is used in precise positioning systems where it is critical to stop air flow completely in the neutral position.

- Mid-position exhausted: In the middle position, the working ports are connected to the exhaust, allowing air to escape. This configuration is used in pneumatic braking systems where it is necessary to release pressure in the neutral position.

Reset mechanisms

Festo VHEF valves offer multiple reset methods to ensure reliable operation. The mechanical spring reset is common in monostable valves, using a spring mechanism to return the valve to its default position when not actuated, providing a fail-safe mechanism. Alternatively, some valves use a pneumatic spring, utilizing air pressure for a more dynamic reset.

Additionally, Festo VHEF valves provide options for pilot air supply. Valves with internal pilot air supply use the same air source that operates the valve, simplifying setup and reducing additional air lines. In contrast, valves with external pilot air supply require a separate air source, beneficial for applications needing different pressures for the pilot and main air supply.

Ordering a particular valve type

Check the type code provided in the product listing or datasheet. Also, look at the valve function section in the datasheet to understand the specific configuration. For example, a valve with type code VHEF-HS-B53E-G14 means:

- VHEF: Manually actuated valve series

- HS: Hand lever on the side

- B53E: 5/3-way valve, detenting, mid-position exhausted

- M: Mechanical spring reset

- G14: G1/4 connection

The datasheet provides a comprehensive guide to the specifics of each part of the type code, ensuring the user accurately interprets and selects the correct valve configuration for the application needs.

Figure 2: Festo VHEF selector valve type code

Technical specifications

- Construction width: 20 mm

- Sealing principle: Soft, ensuring tight sealing

- Flow direction: Reversible

- Operating pressure: -0.95 to 10 bar (-13.8 to 145 psi)

- Media temperature: -10 to 60𐩑 C (14 to 140 𐩑F)

Selection criteria

- Determine the valve function: Choose a 3/2-way valve for simple on/off control, ideal for single-acting cylinders. Opt for a 5/2-way valve for applications requiring two positions, such as double-acting cylinders and complex circuits. Select a 5/3-way valve if you need three positions, providing a mid-position for safety or control, like stopping a cylinder mid-stroke.

- Select actuation type: The Festo VHEF valve can be actuated in multiple ways (using pushbutton, hand lever, toggle lever, finger lever, or selector switch) based on the specific application requirements and user preferences.

- Check flow rate, temperature, and pressure requirements: Ensure the valve's flow rate, temperature, and pressure range meets the system's needs.

- Verify connection sizes: The Festo VHEF valve is available in two connection sizes, G1/8 for smaller connections and G1/4 for larger connections.

- Consider mounting options: The Festo VHEF valve offers front panel mounting for easy access and visibility, and through-hole mounting for secure and stable installation.

- Material: The valve has anodised aluminum housing, PA-reinforced cover, and NBR seals. Ensure the materials are compatible with the operating environment.

Example of connecting valve ports with accessories

Figure 3: Festo VHEF hand lever valve port connections: pneumatic supply port (1), working ports (2, 4), and exhaust ports (3, 5)

Consider a 5/2-way hand lever valve with G1/4 ports. The valve has five ports:

- Port 1: Pneumatic supply port

- Port 2: Working port 1

- Port 3: Exhaust port 1

- Port 4: Working port 2

- Port 5: Exhaust port 2

Connect the air supply to Port 1 using a push-in fitting. Connect Port 2 to the actuator using a fitting and necessary tubing. Attach a silencer to Port 3 for exhaust. Connect Port 4 to the actuator using a fitting and tubing. Attach a silencer to Port 5 for exhaust.

To mount the valve, use the mounting holes provided on the valve body, typically designed for M4 screws. Secure the valve to a panel or mounting surface using the appropriate screws. Ensure the valve is mounted in a position that allows easy access to all ports for maintenance and adjustments.

Note: Users can select the necessary accessories based on the valve's port size, tubing outer diameter, and the specific application requirements such as noise reduction and secure connections. Ensure to choose the correct fittings, tubing, and silencers that match the valve's specifications and the pneumatic system requirements.