Globe Valve Vs Diaphragm Valve

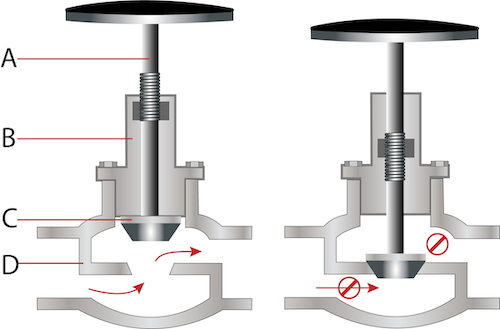

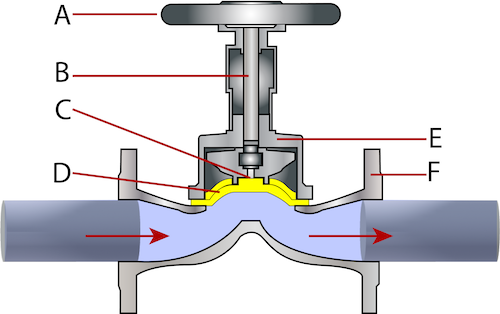

Figure 1: Globe valves (left) and diaphragm valves (right) are commonly used throughout industrial applications.

Globe valves and diaphragm valves are integral components in controlling fluid flow in various industrial applications. Despite their different designs and operating mechanisms, they can sometimes serve similar purposes. Understanding each valve type's basic functions and workings is essential for selecting the correct valve for a specific application.

Table of contents

View our online selection of valves!

Globe valves

Globe valves are selected because they provide excellent precision and control. The key components of a globe valve include a movable disk (or plug) and a stationary ring valve seat in a generally spherical body. The disk moves perpendicularly to the seat, creating a variable opening that controls flow through the valve. As the handle or actuator is turned, the disk moves closer to or further from the seat, adjusting the flow rate accordingly. This design allows for precise flow control, making globe valves ideal for throttling applications where the flow needs to be adjusted regularly. Typical globe valve applications are:

- Water flow control

- Steam service

- Cooling systems

- Fuel oil systems

- Gasoline and lubricating oil systems

- Chemical feed

- Condenser air extraction

- Boiler vents and drains

Figure 2: Open globe valve (left) and closed globe valve (right): stem (A), bonnet (B), plug or disc (C), and valve body (D).

Diaphragm valves

Diaphragm valves are selected for their excellent sealing and compatibility features. These valves control flow by moving a flexible diaphragm up and down to open or close the flow path. The valve body typically contains a weir or saddle upon which the diaphragm sits. When the valve is closed, the diaphragm presses against the weir, sealing the valve and stopping the flow. As the valve opens, the diaphragm lifts, allowing fluid to pass through. This design provides an effective seal and isolates the fluid from the valve's mechanical parts, making diaphragm valves suitable for applications involving corrosive fluids or slurries. The material of the diaphragm can be selected based on the fluid's properties, enhancing the valve's compatibility with various media. Common diaphragm valve applications are:

- Water treatment

- Chemical processing

- Food and beverage

- Pharmaceutical manufacturing

- Mining operations

- Pulp and paper industry

- Biotech applications

Figure 3: Diaphragm valve with components: handle (A), stem (B), compressor (C), diaphragm (D), bonnet (E), and valve body (F).

Selecting between a diaphragm valve and globe valve

-

Media compatibility

- Diaphragm valve: Suitable for handling corrosive fluids, slurries, and viscous materials. The diaphragm material (e.g., EPDM, PTFE, NBR) must be compatible with the media to prevent degradation.

- Globe valve: Best for gasses and liquids, including steam. Material selection for the valve body and seals (e.g., stainless steel, bronze, PTFE) is crucial for media compatibility.

-

Temperature ratings

- Diaphragm valve: Typically rated for temperatures between -60°C to 200°C (-76𐩑 F to 392 𐩑F) , depending on the diaphragm material. PTFE diaphragms can handle higher temperatures, while EPDM diaphragms are suited for lower-temperature applications.

- Globe valve: Generally rated for temperatures from -196°C (-320 𐩑F) up to 600°C (1112 𐩑F), making them suitable for high-temperature applications. The exact rating depends on the body and trim materials.

-

Pressure ratings

- Diaphragm valve: Usually suitable for lower pressure applications, typically up to 16 bar (232 psi). The flexible diaphragm limits the valve's ability to handle high pressures.

- Globe valve: Can handle higher pressure drops, with ratings up to 400 bar (5800 psi). Their design allows for better control under high-pressure conditions.

-

Flow control and regulation

- Diaphragm valve: Offers excellent on/off and throttling capabilities, especially for applications involving corrosive or particulate-laden fluids. However, they may not provide as precise control as globe valves.

- Globe valve: Excellently suited for precise flow control and regulation, thanks to the linear motion of the valve stem and the shape of the valve seat and disc.

-

Maintenance and durability

- Diaphragm valve: The diaphragm serves as both a seal and a moving part, which minimizes leak paths but requires replacement over time due to wear and tear.

- Globe valve: Contains more mechanical parts (e.g., stem, disc, seat) which can wear out but are generally easy to repair or replace. They tend to have a longer lifespan in high-cycle applications. Learn more in our globe valve maintenance article.

-

Cost considerations

- Diaphragm valve: Generally less expensive initially, but the cost of replacement diaphragms over the valve's lifecycle can add up.

- Globe valve: May have a higher initial cost but can be more cost-effective in the long run due to their durability and repairability.

-

Application specifics

- Diaphragm valve: Ideal for applications requiring sterile or clean operations, such as in the pharmaceutical or food and beverage industries.

- Globe valve: Preferred for applications demanding precise flow control, such as in HVAC systems, steam distribution, and process industries.

FAQs

What is the main difference between a globe valve and a diaphragm valve?

The main difference is their operation; globe valves use a disk to stop flow, while diaphragm valves use a flexible diaphragm.

How does a globe valve work?

A globe valve controls flow by moving a disk into or away from the seat, adjusting the flow passage size.

What are the parts of a diaphragm valve?

Parts include the body, bonnet, diaphragm, stem, and handwheel or actuator.

When should I use a diaphragm valve over a globe valve?

Use a diaphragm valve for applications requiring tight shut-off, handling corrosive fluids, or where contamination is a concern.