JIC vs AN Fitting Differences

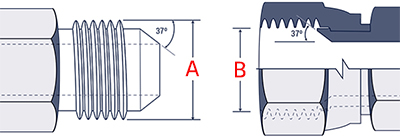

Figure 1: An example of a AN fitting (top) and a JIC fitting (bottom)

JIC (Joint Industries Council) and AN (Army-Navy) fittings are widely used in hydraulic and pneumatic applications. However, they serve distinct purposes and adhere to different standards. Selecting between JIC and AN fittings depends on the application's specific requirements:

- AN fittings are ideal for high-stress, precision environments such as military and aerospace applications.

- JIC fittings are more suited for general industrial use due to their cost-effectiveness and adequate performance standards.

View our online selection of threaded fittings!

Table of contents

- Design and thread specifications

- Standards and applications

- Measurement and compatibility

- AN and JIC fitting sizes

- Thread fit classes

- FAQs

Design and thread specifications

JIC and AN fittings have a 37° flare connection and straight threads. This facilitates a secure seal between the male and female components. However, the thread specifications differ significantly:

- AN fittings: AN fittings use class 3A/3B UNJ/UNJF root threads. This design enhances the tensile stress area and reduces stress concentration. This results in stronger threads with tighter tolerances, making AN fittings suitable for high-stress environments such as aerospace and military applications.

- JIC fittings: JIC fittings conform to class 2A/2B UN/UNF series threads. The design offers a balance between performance, manufacturing efficiency, and cost.

Standards and applications

- AN fittings: Developed for military aviation, AN fittings adhere to MIL-F-5509 and AS4841 specifications. They are designed for high-performance applications in military and commercial aviation sectors.

- JIC fittings: JIC fittings, governed by the SAE J514/ISO 8434-2 standards, are used in industries such as agriculture, construction, and automotive. They are less expensive and produced to a slightly lower standard compared to AN fittings.

Measurement and compatibility

Both AN and JIC fittings are measured by the male connection's outer diameter and the female connection's inner thread diameter. Despite using the exact dimensions, AN and JIC fittings are not interchangeable due to thread quality and standard differences.

Table 1: JIC vs AN fittings

| Category | JIC fittings | AN fittings |

| Full Name | Joint Industrial Council | Army-Navy |

| Application focus | Industrial, agricultural, automotive | Aerospace, military |

| History | Created after WWII as a cost-effective version of AN fittings | Originated during WWII for military applications |

| Sealing geometry | 37° flaring | 37° flaring |

| Material | Typically, steel or stainless steel | Typically, aluminum or stainless steel |

| Thread specification | Standard UN/UNF threads | J-profile UNJ/UNJF threads |

| Precision level | Class 2 (Standard precision) | Class 3 (Enhanced precision) |

| Pressure rating | Moderate | High |

| Governing specifications | SAE J514/ISO 8434-2 | MIL-F-5509 |

| Cost | Low | High |

AN and JIC fitting sizes

AN and JIC fittings share the same physical dimensions. Table 1 shows how these sizes correspond to physical measurements. For example, consider a "-6" dash size:

- It corresponds to a female thread with an inside diameter of 12.7 mm.

- The male thread has an outside diameter of 14.3 mm.

- The thread size is 0.5625 inches.

- It has 18 threads per inch.

Note: The dash size for JIC fittings is the tube size in sixteenths of an inch. For example, sash size -6 = 6/16" = 3/8" tube.

Figure 2: Male JIC fitting outer diameter (A) and female JIC inner diameter (B)

Table 1: AN and JIC fittings chart

| Dash size | Female thread inside diameter (mm) | Male thread outside diameter (mm) | Thread size | Threads per inch |

| -2 | 6.7 | 7.9 | 0.3125 | 24 |

| -3 | 8.3 | 9.5 | 0.375 | 24 |

| -4 | 9.9 | 11.1 | 0.4375 | 20 |

| -5 | 11.5 | 12.7 | 0.5 | 20 |

| -6 | 12.7 | 14.3 | 0.5625 | 18 |

| -8 | 17.5 | 19.1 | 0.75 | 16 |

| -10 | 20.6 | 22.2 | 0.875 | 14 |

| -12 | 24.6 | 27 | 1.0625 | 12 |

| -14 | 28.2 | 30.2 | 1.1875 | 12 |

| -16 | 31.4 | 33.3 | 1.3125 | 12 |

| -20 | 39.3 | 41.3 | 1.625 | 12 |

| -24 | 45.6 | 47.6 | 1.875 | 12 |

| -32 | 61.5 | 63.5 | 2.5 | 12 |

Thread fit classes

- Class 1A and 1B: These threads have loose tolerances, allowing for quick assembly and disassembly. They are rarely used due to their lack of precision.

- Class 2A and 2B: These threads offer a balanced fit, optimizing performance and cost. They are the most common, used in 90% of fasteners, and are standard for SAE J514/ISO 8434-2.

- Class 3A and 3B: These threads have tight tolerances, making them suitable for safety-critical applications. They are used in SAE Aerospace and MIL-F-5509 standards.

FAQs

Can I combine AN and JIC couplings?

AN fittings are made to a much higher standard than JIC/SAE fittings and are much more expensive. Therefore, it is not recommended to use these interchangeably.

What are AN fittings used for?

AN fittings are used extensively in the U.S. military, military contractors, general aviation, and commercial aviation. They are specifically designed to a high standard.

What are JIC fittings used for?

JIC fittings are widely used in agriculture, construction, heavy machinery, and automotive industries.

What is the difference between JIC and AN threads?

JIC and AN threads are similar, but AN threads have tighter tolerances and are used in aerospace, while JIC is used in industrial applications.