O-ring Sizes

Figure 1: Measuring the inner diameter of an o-ring using a vernier caliper

O-rings provide leak-proof seals between two surfaces. An incorrectly sized o-ring can result in leakage. O-rings are available in different sizes, materials, and configurations to fit various applications.

Understanding the different size standards, the users can determine which size o-ring will fit their application. Each standard has its sizes, tolerances, and designations that determine the size and shape of the o-ring.

Table of contents

View our online selection of o-rings!

Measuring o-rings

Knowing how to measure an o-ring is essential to ensure the right size and type of o-ring is selected for a particular application. Various tools are available for measuring o-rings, including o-ring gauges, digital calipers, and micrometers. Accurate measurements are essential for several reasons.

- Selecting the correct size of an o-ring ensures proper sealing and prevents leakage.

- If the o-ring is too small, it may not seal properly, allowing fluids or gasses to leak through the seal.

- If it is too large, it may not fit into the groove or hole or be overstretched and prone to damage.

- O-rings that are improperly sized may be subject to premature wear or failure.

- Measuring o-rings is important to get a proper replacement in case of damage or wear.

How to measure o-rings

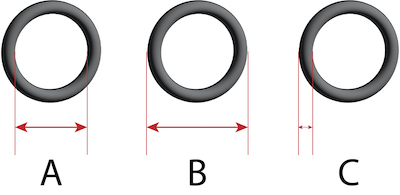

Figure 2: O-ring measurement: inner diameter (A), outer diameter (B), and cross-section (C)

O-rings are typically measured in millimeters. First, position the o-ring on a flat and leveled surface. Determine the various sizing parameters (Figure 2):

- Inner diameter (A): Use a ruler or caliper to measure from one inner edge to another (Figure 1).

- Outer diameter (B): Use a ruler or caliper to measure from one outer edge to the opposite outer edge.

-

Cross-section (C):

- Place the o-ring into a vernier caliper.

- Clamp the caliper jaws onto the o-ring.

- Note the thickness of the ring; the thickness is equal to its cross-section.

Figure 3: Measuring the o-ring outer diameter using a caliper

Measurement formulas

With only two of the three measurements available, it is possible to calculate the third sizing parameter using the following equations:

O-ring sizing standards

Numerous international standards exist for o-ring sizes. Opting for an o-ring size from an established standard is convenient, as it will be readily available and interchangeable.

AS 568 (or AS 568-A)

AS stands for 'Aerospace Standard' and is commonly referred to as an American standard as it was established by the US Society of Automotive Engineers (SAE). AS 568 standard is recognizable due to the thicknesses of the o-rings, which include 1.78 mm, 2.62 mm, 3.53 mm, 5.33 mm, and 6.99 mm. AS 568, specifically AS 568-A, is likely the most widely used standard for o-ring sizes across the globe.

ISO 3601

ISO has incorporated the dimensions of AS 568 into its ISO 3601 standard.

DIN 3771

'DIN' stands for 'Deutsches Institut für Normung,' a German organization that sets standards for various industries. The standard 'DIN 3771' is an older specification that is not as commonly used today but can still be found on older technical drawings. The sizes of o-rings specified by this standard are still encountered quite frequently, even outside of Germany. Unlike many other o-ring standards, DIN 3771 employs no other numerical or coding system to indicate different sizes.

BS 1806 and BS 4518

There are two sets of British Standard (BS) specifications for O-ring sizes: BS 1806 and BS 4518. BS stands for 'British Standard.' The o-ring sizes specified by BS 1806 are very similar to those set by ISO 3601 and AS 568. BS 4518, on the other hand, is mainly used within the United Kingdom.

French R

The French standard for o-ring sizes shares some common sizes with the ISO 3601 and AS 568 standards, but it also includes some unique sizes within its range. The o-ring types in this standard are identified by the letter R followed by a number, such as R12.

JIS B 2401

The JIS standard refers to the Japanese Industrial Standard, and within it, B 2401 is the standard for O-rings in Japan. These O-rings are classified according to different applications, with the letters P, G, S, and V being added to indicate specific uses. P is used for dynamic applications, G for static, S for special circumstances, and V for vacuum.

Non-standardized

Metric sizes are not standardized to their exact size; instead, they are typically rounded to the nearest millimeter or specified with an accuracy of half a millimeter.

O-ring customization

If the user cannot locate an appropriate O-ring size despite having all the information mentioned earlier, customization may be the only viable solution. Although it may not be a cost-effective solution, it might be the only or optimal in certain circumstances.

FAQ

What is an o-ring measuring tool?

An o-ring measuring tool is a device used to measure the o-ring dimensions, like its inner and outer diameters and cross-section. Examples include handheld calipers, digital micrometers, and specialized o-ring gauges.