How Does a Piezo Valve Work

Figure 1: A piezo valve

Piezo valves precisely control fluid flow using the piezoelectric effect, allowing them to actuate with high accuracy and without needing energy to maintain their state. These valves are characterized by their compact size, lightweight, and exceptional durability and speed, making them energy-efficient and capable of operating without generating heat or noise. Notably, piezo valves function proportionally and exhibit significant wear resistance. Such features make them suitable for applications demanding precise flow and pressure control, including the semiconductor industry for accurate air or gas metering, minor parts assembly with precise adhesive metering, and various applications in medical technology, laboratory automation, and the automotive sector.

What is piezo technology?

Piezo technology involves the use of piezo elements, which are electromechanical transducers. These elements can convert mechanical forces such as pressure, tensile stress, or acceleration into electrical voltage through the direct piezoelectric effect. Conversely, the inverse piezoelectric effect occurs when an applied voltage causes the piezo element to deform, generating mechanical motion or oscillations.

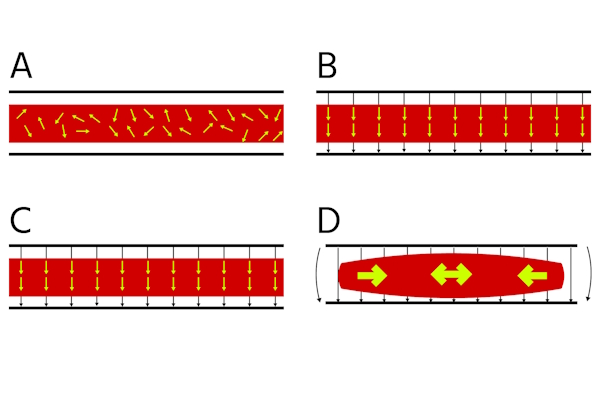

Piezoelectric materials, typically special ceramics with conductive surfaces, facilitate converting electrical and mechanical energy. These materials have an asymmetrical lattice structure below a certain temperature, known as the Curie temperature, making them dipoles. These ceramics can be permanently polarized when exposed to strong electric fields, giving them piezoelectric properties. This polarization causes the material to change shape when voltage is applied, resulting in 3D deformation along the field lines and shrinkage at right angles to these lines.

Advantages of piezo valves

Piezo valves offer several distinct advantages over traditional solenoid valves. Below is a concise list highlighting the main advantages of piezo valves:

- Low energy consumption: Piezo valves use minimal energy to stay active, generating no heat unless high-frequency control is applied. This makes them ideal for battery-powered devices, extending battery life significantly compared to solenoid valves.

- Intrinsic safety: These valves meet the "intrinsic safety" requirements for explosive environments, as they store minimal energy, reducing the risk of ignition.

- High switching speed: Capable of operating in the submicrosecond range, piezo valves are perfect for applications requiring rapid response, such as high-speed sorting systems and closed-loop control circuits.

- Anti-magnetic properties: Piezo technology functions reliably in high magnetic field environments, such as magnetic resonance imaging (MRI) systems.

- Minimal weight: Typically made from plastic and lacking iron and copper components, piezo valves are lightweight and portable.

- Low costs: Mass production of piezo technology can be cost-effective, as seen in inexpensive piezo-ignited lighters.

- Long service life: With a single solid-state component and no friction-prone parts, piezo valves can achieve a high number of operating cycles when properly designed.

Note: Not all these advantages can be fully realized in a single valve, as designs are usually tailored to specific applications where certain benefits are prioritized.

Piezo valve designs

The following components are common in piezo valves:

- Piezoelectric actuator: Converts electrical energy into mechanical movement to control the valve's operation.

- Valve body: Houses all internal components and provides structural integrity.

- Inlet port: Entry point for the liquid or gas to enter the valve.

- Outlet port: Exit point for the liquid or gas to leave the valve.

- Sealing element: Ensures a tight seal to prevent leaks when the valve is closed.

- Electrical connectors: Provide the interface for electrical signals to control the actuator.

- Mounting bracket: Allows the valve to be securely attached to a surface or system.

- Control electronics: Manage the operation of the piezoelectric actuator based on input signals.

Piezoelectric actuator styles

Bender actuators

Bender actuators are rectangular and conductive on both surfaces. This ceramic is bonded to a conductive substrate, forming electrodes. When voltage is applied, the ceramic expands along the electric field, causing the actuator to bend at its free end. These actuators come in various versions with different force and motion characteristics, making them suitable for applications like pneumatic valves, circular knitting machines, and Braille modules. A notable variant is the trimorph, which includes an additional ceramic layer, enhancing performance and temperature range.

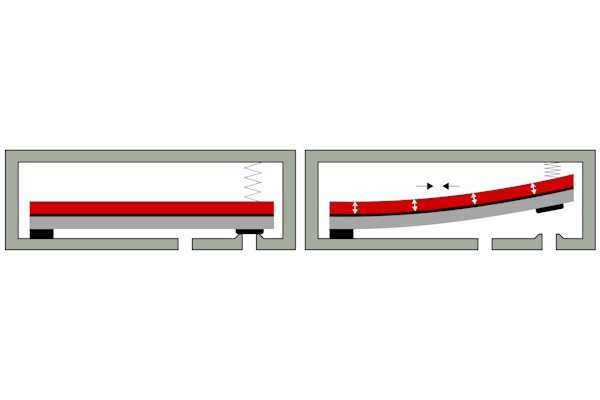

Figure 2: A bender transducer piezo valve is fixed on one end and spring attached on the other (left). When actuated, the unfixed end moves to actuate the valve (right).

Disc transducers

Disc transducers are simple piezo elements shaped as thin ceramic discs attached to metal substrates. The surface of the disc is metalized to create an electric field when voltage is applied. This causes the ceramic to expand, increasing the disc's thickness while reducing its diameter, resulting in a spherical bending motion. This bending effect is utilized in high-frequency loudspeakers, sensors, micropumps, fans, and ultrasound generators, commonly found in automotive distance sensors.

Stack transducers

Stack transducers, or piezo stacks, consist of multiple piezo discs stacked mechanically in series and connected electrically in parallel. Unlike disc transducers, their operation is based on direct expansion along the electric field, allowing for short strokes but generating significant actuating forces. These transducers are used in applications requiring high force, such as liquid valves in diesel fuel-injection systems and micro-positioning devices.

Table 1: Displacement and generated force of bender, disc, and stack transducers

| Transducer type | Bender | Disc | Stack |

| Displacement | 100 - 1000 µm | 10 - 100 µm | 10 - 100 µm |

| Force | 0.1 - 2 N | 1 - 10 N | 1,000 - 10,000 N |

Operating principle

This section describes the operating principle of a typical piezo valve:

- Piezo element utilization: Piezo valves primarily use bender actuators made from piezo elements. The performance of these valves improves with a stronger electric field.

- Energy efficiency: Unlike solenoid valves, piezo valves do not require a continuous current to maintain their state. They need a higher supply voltage only during the initial switch-on phase, consuming significantly less energy overall.

-

Switch-on energy calculation: The energy required to switch on a piezo valve can be approximated using the formula:

where (C) is the capacitance and (U) is the control voltage. Typically, this energy ranges from 0.5 to 5 milliwatt-seconds (mWs).

- Maintaining valve state: Once activated, piezo valves maintain their state even if the power supply is disconnected. This is because the charge carriers cannot flow away without an active discharge.

- Resetting the valve: To reset the valve, the charge must be removed from the transducer. This can be done by either storing the energy in another system (energy recovery) or converting it to heat (short circuit). Therefore, a changeover switch is necessary instead of a simple on-off switch.

- High-voltage generation: High-performance piezo valves require high voltage, which can be efficiently generated using a boost converter. This device uses the high induction voltage from a coil's cyclical switch-off, storing it in a capacitor.

- Boost converter operation: A boost converter can achieve an output voltage of 300 V from an input as low as 1 V. The oscillator for the switch can often be integrated into the system's existing microprocessor, or specialized integrated circuits can be used.

- Efficiency and regulation: Integrated circuits designed for this purpose manage output voltage regulation and ensure high efficiency, often exceeding 80%.

Figure 3: The ceramic actuator (A) is permanently polarized when it's in a strong electric field (B) and maintains this polarization when the electric field turns off (C). When voltage is applied, the ceramic material deforms among the field lines (D).

Piezo valve applications

The following list contains common piezo valve applications:

- Flow control in semiconductor production for coating and bonding processes

- Non-destructive handling of fragile workpieces using speed controllers for double-acting pneumatic cylinders

- Fast and accurate metering in industrial adhesive applications

- Precise control of flow rates in various industrial applications

- Polishing wafers in semiconductor production by controlling pressure and vacuum

- Mobile ventilators in medical technology for compact, energy-efficient, and quiet operation

- Pneumatically powered surgical tools in ophthalmology for cataract surgery

- Inflating air cushions in car seats for enhanced comfort and support

- Bionic Handling Assistant for precise and purposeful metering of compressed air

Selection criteria

The following selection criteria for a piezo valve are created using the characteristics of Festo's piezo valve (VEVM). Use these characteristics to know what to focus on when selecting piezo valves.

General data

- Reset method: Spring

- Closing mechanism: Piston seat

- Flow direction: Non-reversible

- Status indication: A blue LED means normal function. A red LED means malfunction.

- Nominal size: 4.2 mm

- Standard nominal flow rate: 450 l/min

- Weight: 200 g

- Protection: IP65

Operating and environmental conditions

- Operating medium: Compressed air (ISO 8573)

- Lubrication: Not allowed

- Operating pressure: 3 - 8 bar (43.5 - 116 psi)

- Operating temperature: 5 - 45 °C (41 - 113 °F)

Electrical data

- Operating voltage: 24VDC

- Allowed voltage fluctuations: +/- 25%

- Power consumption: 2W

- Duty cycle: 100%

Pneumatic connections

- G3/8: Supply, exhaust

- G1/8: Working ports

- M5: Pilot air supply

- M7: Pilot exhaust, venting hole

Materials

- Housing: PA

- Seals: TPE-U(PU), NBR

FAQs

How does a piezo valve work?

A piezo valve works by using a deformable piezoelectric actuator to control the valve opening, allowing precise regulation of fluid flow.

What is a piezo valve actuator?

A piezo valve actuator is a component that converts electrical signals into mechanical movement using the piezoelectric effect to control valve operation.

What are the applications of piezo valve technology?

Piezo valve technology is used in semiconductor manufacturing, medical devices, laboratory automation, and automotive systems for precise flow and pressure control.