Rigid vs Flexible Couplings for Industrial Applications

Figure 1: Flexible set screw coupler. The spiral cuts around the body allow the coupling to slightly flex during misalignment.

Industrial applications regularly use rigid and flexible couplings to connect shafts. These couplings transfer torque from one shaft to another. Rigid shafts transfer more torque but require no misalignment between the shafts. Flexible couplings allow for some misalignment, typically up to 5° in parallel, axial, or angular directions. This article provides an overview of rigid and flexible couplings and offers example applications for each type.

Types of rigid and flexible couplings

There are various types of rigid and flexible couplings within industrial applications. It is important to first understand the application requirements to then know what parameters to look for in a coupling. The overview below is not a complete list, but gives an overview of the common types.

Rigid couplings

Rigid couplings connect shafts that are perfectly aligned. These couplings cannot compensate for misalignment during operation but can transfer higher torques. They are simple and cost-effective couplings and come in a variety of styles that make them application specific:

- Flanged couplings: Flanged couplings consist of two separate flange ends that bolt together. These couplings can handle heavy loads and have diameters larger than 200 mm (8 in). Flanged couplings can connect shafts of different diameters.

- Ribbed couplings: Also called clamp couplings, ribbed couplings connect shafts of the same diameter. These couplings are split through the center along their length. The two coupling pieces fit over the ends of two shafts to join them together. Then the coupling's two pieces are joined with bolts. These couplings are easy to install and are suitable for medium to high speeds.

- Sleeve couplings: Sleeve couplings are simple to use and install. The shaft ends insert into opposing ends of the sleeve, and set screws tighten the sleeve coupling to the shafts. These couplings are suitable for light to medium-duty applications.

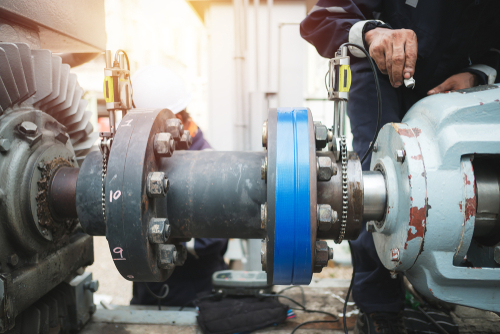

Figure 2: A flanged coupling connects an electric motor to a pump.

Flexible couplings

Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. The primary difference is that flexible couplings allow for some misalignment between the two shafts in an angular, parallel, or axial direction. Some couplings allow for misalignment in a combination of directions.

- Set screw couplings: A set screw coupling (Figure 1) connects two shafts together at their ends for the purpose of transmitting power. It contains one or more set screws that tighten against the shafts to secure them in place and prevent slippage. The spiral cuts around the coupling's body allow for slight flexibility.

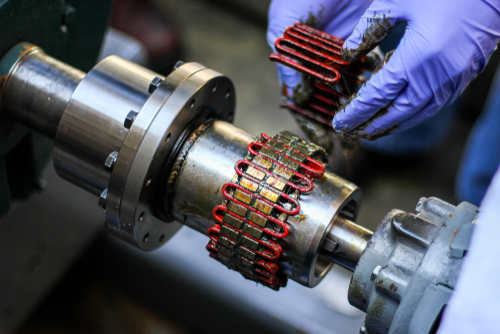

- Gear couplings: Gear couplings transmit the most torque of any flexible coupling. These couplings consist of two hubs with external gear teeth that are an external/internal pair. The flanks of the gear teeth are designed to allow for up to 4° to 5° of misalignment.

- Jaw couplings: Jaw couplings are often used in continuously running electric motors. They handle angular misalignment up to 1 degree and parallel misalignment up to 0.015 inches. Jaw couplings are popular for being reliable, protective, and versatile.

- Grid couplings: Grid couplings are notable for reducing up to 30% of vibrations and cushion shock in driving and driven power transmission equipment.

- Roller chain couplings: Roller chain couplings are a cost-effective choice for high torque applications found in industries such as agricultural and mining. They permit approximately 2° of misalignment.

Figure 3: Installing a grid coupling.

Selecting couplings for industrial applications

The following is an overview of industrial applications that use rigid or flexible couplings.

Rigid coupling applications

- High-speed rotating machinery: Turbines, high-speed pumps, and compressors use rigid couplings. Precise alignment is necessary to prevent vibration which inhibits smooth operation.

- Precision CNC machining: CNC machines use rigid couplings for accuracy and minimal backlash, which are both necessary for cutting, milling, and turning operations.

- Robotics and automation: Automated machinery and robotic systems use rigid couplings for precise motion control and synchronization between multiple axes.

- Power transmission systems: Heavy-duty power transmission applications use rigid couplings for high torque and shaft alignment.

Flexible coupling applications

- Electric motor driven equipment: Electric motors have flexible couplings to connect to pumps, compressors, fans, and other driven equipment to reduce vibration transmissions.

- Automotive industry: Drivetrains and suspension systems use flexible couplings to minimize vibrations and handle any misalignment caused by engine movements.

- HVAC systems:HVAC systems use flexible couplings to connect motors to fans, blowers, and other equipment.

- Marine and offshore applications: Marine propulsion systems, offshore drilling rigs, and ship-to-shore equipment use flexible couplings to handle misalignments caused by vessel movements.

FAQs

Why are flexible couplings preferred over rigid couplings?

Flexible couplings are preferred over rigid couplings for applications where misalignment between the shafts can occur.

Why use rigid coupling?

Use rigid coupling for applications in which there is no misalignment.