How To Use Screw Clamps

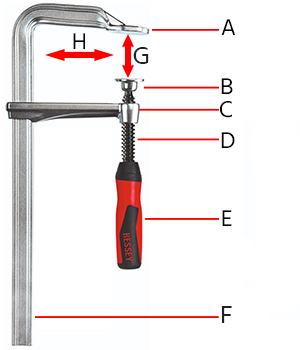

Figure 1: Screw clamp

A screw clamp is a tool designed to join or hold two or more objects firmly together. It uses a screw mechanism to adjust its jaws and clamp a workpiece in place. It is useful when holding or gluing components, for example, wood, paper, plastic, or various metals. A screwable screw clamp is one of the simplest and least expensive clamps available today.

Unlike most clamps, screw clamps provide designers with a variety of clamping options. It is an excellent workholder because it clamps effectively and has excellent size-to-force ratio. Yet they also have a disadvantage: their slow clamping speed makes them impractical for high-volume jigs and fixtures.

View our online selection of screw clamps!

Table of contents

- How do screw clamps work?

- Types of screw clamps

- Tips for using a screw clamp

- How to use a screw clamp

How do screw clamps work?

Figure 2: A screw clamp with a movable jaw: Fixed jaw (A), clamp foot (B), sliding jaw (C), spindle (D), handle (E), profile rail (F), opening (G), depth (H)

Most screw clamps have a movable jaw attached to an adjustable screw, although there are variations to this. These clamps are typically temporary devices, but permanent models are also available. Figure 2 illustrates the various parts of a screw clamp with a movable jaw.

Screw clamps work through the use of a screw thread on an inclined plane, either an ACME or trapezoidal thread (figure 2 labeled D). The acme thread has a flank angle of 29 degrees, adopted in the United States, while the trapezoidal thread has a 30-degree flank angle, adopted in Europe. Learn more about threads in our thread standards guide. The inclined plane becomes a helix when applied to a cylinder. As a result of the helical shape of the thread, it can transmit lateral movement along the screw's axis. The lateral movement that occurs as the screw is turned will open or close the clamp.

Perhaps the most important factors when choosing a screw clamp are the opening and depth of the clamp. The opening (Figure 2 labeled G) refers to the full opening distance a clamp can achieve. The depth (Figure 2 labeled H) refers to the distance the clamp has between the opening and the profile rail.

Types of screw clamps

There is a huge variety of clamps available on the market. From simple screw clamps, one-handed clamps, light-duty bar clamps, and self-adjusting toggle clamps used for welding applications. They also typically adhere to DIN 5117. Below, we describe the three most common variations. While they look and perform similarly, there are a few differences between the various designs:

Figure 3: From left to right: malleable-cast-iron clamp, all steel clamp, and a light duty U-style clamp

- Malleable cast-iron screw clamps: These clamps have robust, tempered cast iron parts. They find their application mainly in woodworking sections and come with non-slip surfaces, which prevent loss of clamping force and slipping of the sliding jaw.

- All-steel screw clamps: On steel clamps, the fixed jaw is made from one piece of solid steel. This makes these clamps incredibly strong. These clamps are mainly used for metal works.

- Light-duty U-style clamp: These clamps are ideal for light clamping applications. The U-shape allows the clamp to reach over workpieces. The light-duty U-style bar clamps have rails made of steel, providing extra strength, the sliding arm is made of die-cast zinc. This type of clamp is light, stable, break-resistant, and has protective caps to work with sensitive workpieces.

Tips for using a screw clamp

Follow our tips and tricks below to ensure you always have a great result when using a screw clamp:

- Always make sure the pressure pad on your screw clamp spins freely. This will prevent damage or scratching to any workpiece.

- Screw clamps are designed to apply their maximum holding force in their intended use, which means tightened by hand. Using wrenches or pliers will either damage or destroy the clamp and, potentially, your workpiece.

- Tighten the clamp only until you feel resistance. Do not overtighten or force the clamp to close further. Screw clamps are designed to hold an object, not to apply force.

- It can happen that the screw clamp leaves a black mark, especially on woodwork. To prevent this, use a piece of masking tape, wax paper, or tissue paper to protect your workpiece.

- Never use a screw clamp that is bent or fractured. The same counts for the spindle. A bent spindle needs to be replaced.

- Use a size suitable for the project. Using a large screw clamp when a small one would suffice will lead to damage or accidents.

How to use a screw clamp

Follow these simple steps. There may be slight differences depending on the screw clamp.

- Open jaws: The clamp needs to be opened before it can be used. This is accomplished by twisting the handle to the left, which loosens the screw and separates the moveable jaw from the fixed jaw. Multi-handled clamps are possible. For clamps with multiple handles, twisting each individually will open all the jaws simultaneously. Position the clamp, so the open jaws are over the workpiece.

- Position clamp: Orient the clamp, so the jaws are on either side of the workpiece. Objects can be clamped to worktops using a clamp. Your clamp may be used for applications such as filing or drilling that require the workpiece to be placed on a work surface. Placing one jaw of the clamp on top of the workpiece and the other under the work surface so that the frame of the clamp surrounds the edge of the worktop is the best way to use a clamp in this situation. Remember to use a piece of masking tape, wax paper, or tissue paper to protect your workpiece, and twist the handle to the right to close the jaws together.

- Close jaws: Turn the handle to the right to close the jaws. The jaws will move closer together as the screw is tightened. Secure the workpiece by closing the jaws firmly. For substantial or heavy workpieces, you can use multiple clamps at the same time. When working with large workpieces, use several clamps to provide additional support. With the workpiece now secured, the desired task can be carried out.

Read our clamp types article for information on the various types of clamps.