Select the right housing material for your solenoid valve

Figure 1: 2/2-way solenoid valve

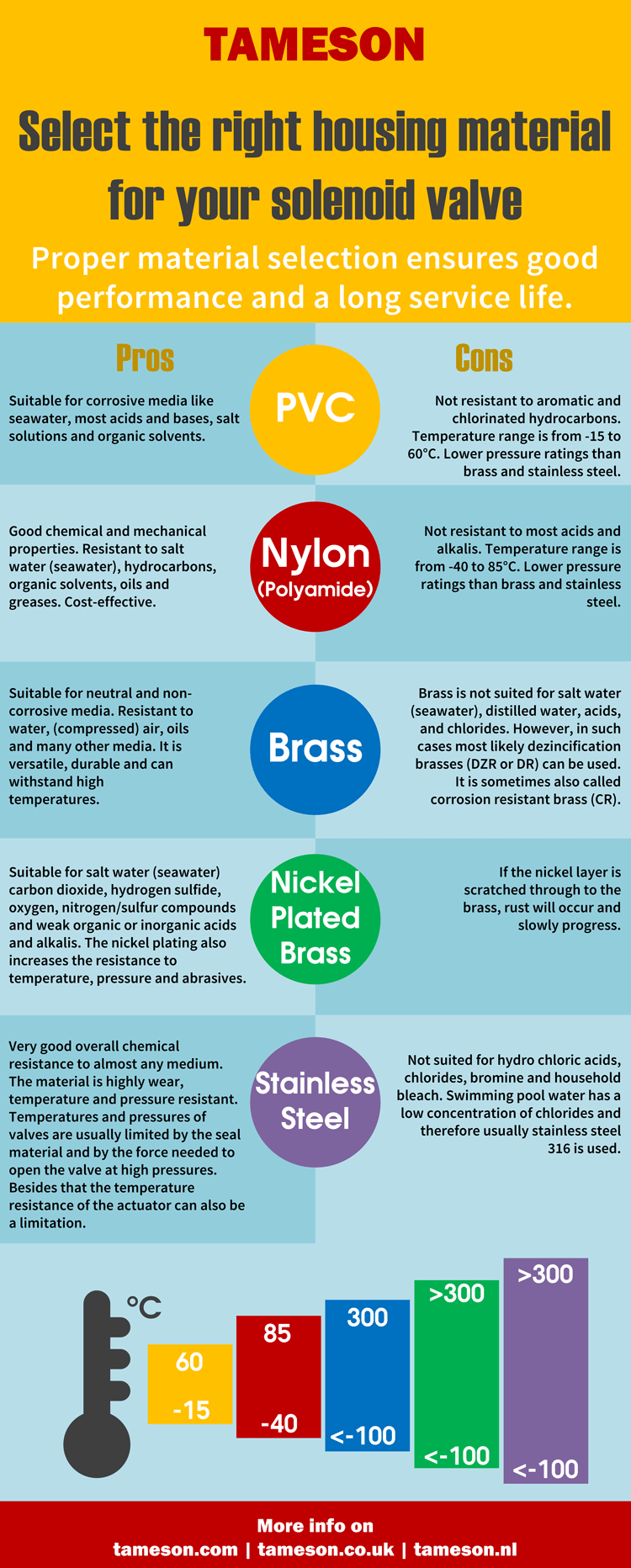

Solenoid valves are commonly available in a variety of housing materials. Typical options include Nylon (Polyamide – PA), PVC (PolyVinylChloride), Brass, Nickel-plated brass, and Stainless Steel (304 and 316). The selection of material is heavily influenced by the chemical properties and temperature of the medium. Choosing the correct material is crucial for ensuring a long lifespan and optimal performance. The infographic below highlights the main benefits of the most significant housing materials.

View our online selection of brass solenoid valves!

Select the right housing material for your solenoid valve - An infographic by Tameson!

Nylon (Polyamide – PA)

Advantages

Good chemical and mechanical properties. Resistant to salt water (seawater), hydrocarbons, organic solvents, oils and greases. Cost-effective.

Disadvantages

Not resistant to most acids and alkalis. Temperature range is from -40 to 85 °C. Lower pressure ratings than brass and stainless steel.

PVC (PolyVinylChloride)

Advantages

Suitable for corrosive media like seawater, most acids and bases, salt solutions and organic solvents.

Disadvantages

Not resistant to aromatic and chlorinated hydrocarbons. Temperature range is from -15 to 60 °C. Lower pressure ratings than brass and stainless steel.

Brass

Advantages

Suitable for neutral and non- corrosive media. Resistant to water, (compressed) air, oils and many other media. It is versatile, durable and can withstand high temperatures.

Disadvantages

Brass is not suited for salt water (seawater), distilled water, acids, and chlorides. However, in such cases most likely dezincification brasses (DZR or DR) can be used. It is sometimes also called corrosion resistant brass (CR).

Nickel plated brass

Advantages

Suitable for salt water (seawater) carbon dioxide, hydrogen sulfide, oxygen, nitrogen/sulfur compounds and weak organic or inorganic acids and alkalis. The nickel plating also increases the resistance to temperature, pressure and abrasives.

Disadvantages

If the nickel layer is scratched through to the brass, rust will occur and slowly progress.

Stainless steel (304/316)

Advantages

Very good overall chemical resistance to almost any medium. The material is highly wear, temperature and pressure resistant. Temperatures and pressures of valves are usually limited by the seal material and by the force needed to open the valve at high pressures. Besides that the temperature resistance of the actuator can also be a limitation.

Disadvantages

Not suited for hydro chloric acids, chlorides, bromine and household bleach. Swimming pool water has a low concentration of chlorides and therefore usually stainless steel 316 is used.

For a more detailed explanation of the different materials, refer to the chemical resistance of materials article. This article also features an extensive chemical compatibility reference table, allowing you to quickly determine the compatibility of housing and/or seal materials with hundreds of chemicals. For more information on the design and operation of solenoid valves, read our solenoid valve overview article.