Temperature Control: Thermometers, Sensors, Switches, and Thermostats

Figure 1: Temperature control devices: Bimetallic thermometers (A), HVAC duct temperature sensor (B), HVAC temperature switch (C), and HVAC manual thermostat (D)

Temperature control devices, such as thermometers, temperature sensors, switches, and thermostats, play a crucial role in monitoring and regulating temperature in various industrial and domestic applications. These instruments ensure that systems operate within safe and efficient temperature ranges, thereby enhancing performance and preventing damage. By providing accurate temperature readings and enabling automated responses, they contribute significantly to maintaining optimal conditions in processes ranging from manufacturing to climate control.

Table of contents

- Thermometer

- Temperature sensor

- Temperature switches

- Thermostats

- Integration of temperature control devices

View our online selection of thermometers!

Thermometer

Figure 2: Bimetallic thermometers

A thermometer is an instrument used to measure temperature. They are crucial for monitoring and controlling processes that require specific temperature conditions. Based on the operation principle, there are different types of thermometers. For instance, a bimetallic thermometer translates the temperature of a medium into mechanical movement through a bimetallic strip. This strip is made of two distinct metals with varying thermal expansion rates. Bimetallic thermometers are commonly found in household appliances such as air conditioners, as well as in industrial equipment like heaters, hot wires, and refineries. They offer a straightforward, robust, and economical method for measuring temperature. However, they are not suitable for extremely high temperatures and need regular calibration.

Temperature sensor

Figure 3: HVAC duct immersion temperature sensor

A temperature sensor is a device that measures temperature and converts the data into a signal that can be read by an observer or by an instrument. The key functions of a temperature sensor are:

- Measurement: Accurately measure the temperature of an environment, object, or substance.

- Conversion: Convert the temperature measurement into an electrical signal (analog or digital) that can be processed by other devices.

- Monitoring: Continuously monitor temperature changes over time.

- Control: Provide feedback to control systems to maintain desired temperature levels.

Temperature sensors are commonly used in industrial automation, HVAC systems, automotive applications, medical devices, consumer electronics, environmental monitoring, and the food and beverage industry.

In HVAC systems, temperature sensors are connected to components such as air handlers, furnaces, and thermostats to deliver accurate temperature readings to a control unit that manages the system. In smart homes, these sensors facilitate zone-based temperature control to minimize energy usage. There are different types of HVAC temperature sensors, each designed for specific purposes and applications.

HVAC average temperature sensors

Average temperature sensors measure the average (mean) temperature across a ductwork section or a large space.

Figure 2: Average temperature sensor

HVAC duct temperature sensors

Duct temperature sensors (Figure 1 labeled B) are specifically designed to measure the temperature of the air flowing within HVAC ductwork. They ensure that air distributed throughout a building is at the desired temperature.

HVAC temperature immersion sensors

Temperature immersion sensors are used to measure the temperature of liquids, such as water in a boiler or chiller system. These sensors are important for systems using water or other liquids for heating or cooling, like hydronic heating or chilled water systems.

Figure 3: HVAC immersion temperature sensor

HVAC contact temperature sensors

Contact temperature sensors are designed to measure the temperature of surfaces, such as ducts, pipes, or equipment casings. These sensors are useful for monitoring specific HVAC components like refrigerant lines or heating coils.

Figure 4: HVAC contact temperature sensor

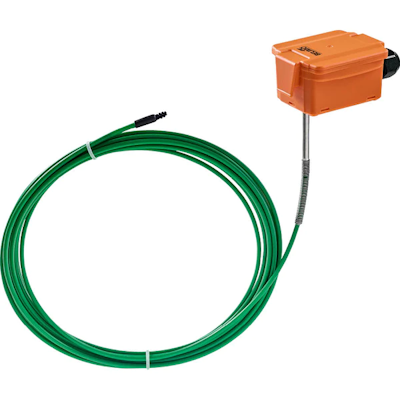

HVAC cable temperature sensors

These sensors measure temperature along lengths of cable, providing distributed sensing capability, and are ideal for tracing temperature changes along ducts, pipes, or entire rooms or zones, especially in complex systems.

Figure 5: HVAC cable temperature sensor

HVAC outdoor temperature sensors

Designed to monitor outdoor temperature, these sensors provide essential data for optimizing indoor heating and cooling based on external conditions, and are particularly useful in environments with significant external temperature fluctuations.

Figure 6: Outdoor temperature sensor

View our online selection of temperature sensors!

Temperature switches

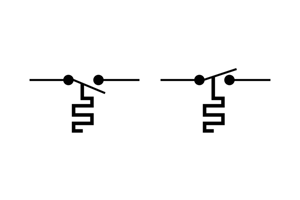

Figure 7: HVAC temperature switch

A temperature switch is a device that automatically responds to temperature changes by opening or closing an electrical circuit. Its primary function is to control the operation of heating, cooling, or ventilation systems based on the temperature of the environment or a specific component. By continuously monitoring and reacting to temperature fluctuations, these switches help prevent overheating or freezing, thereby avoiding equipment damage, inefficiency, and higher energy costs. Furthermore, temperature switches are essential for maintaining a comfortable and safe environment for occupants by automatically adjusting HVAC operations according to the temperature requirements of the space.

In an HVAC system, temperature switches can be installed in multiple locations like:

- air supply ducts to regulate air temperature

- return air ducts to sense and adjust incoming air

- evaporator coils to prevent freezing

- furnaces to shut down the system if overheating occurs

Industrial temperature switches can be mounted using various mechanisms such as:

- direct pipe contact

- thermowell mounting

- wall mounting with a probe in a flange

- wall mounting with a probe in an immersion sleeve

Each mounting method offers flexibility and specific advantages for different installation requirements.

Figure 7: Temperature switch symbol for normally open (left) and normally closed (right) types

View our online selection of temperature switches!

Thermostats

Figure 8: A low-voltage hvac manual thermostat

HVAC thermostats (Figure 1 labeled D) are essential for controlling indoor temperatures, enhancing comfort, and improving energy efficiency. They come in various types:

- Line voltage: Line voltage thermostats, operating at 120 or 240 volts, are directly wired to heating units like electric baseboards and wall heaters, making them suitable for older homes and single-zone systems. They can be single-pole, which must remain powered, or double-pole, which can be completely turned off.

- Low voltage: Low voltage thermostats, operating at 24 to 30 volts, are standard for central HVAC systems and offer advanced features such as programmability, Wi-Fi connectivity, and smart home compatibility, providing precise temperature control across multiple zones.

Thermostat interfaces range from basic manual types to advanced programmable, Wi-Fi, and smart thermostats. Manual thermostats require physical adjustments, while programmable models allow users to set temperature schedules, enhancing energy efficiency. Wi-Fi thermostats enable remote control via mobile apps or web interfaces, ideal for frequent travelers. Smart thermostats use learning algorithms and sensors to optimize heating and cooling patterns, offering energy efficiency, convenience, and potential cost savings, and can integrate with other smart home devices. Read our HVAC thermostat installation guide for more details on installing a thermostat.

View our online selection of thermostats!

Integration of temperature control devices

To achieve optimal performance and efficiency in HVAC and industrial systems, temperature control devices such as thermometers, sensors, switches, and thermostats must be integrated seamlessly.

Temperature switch and duct temperature sensor

A temperature switch activates or deactivates heating and cooling elements based on predefined thresholds. If a duct temperature sensor detects that the air temperature exceeds the desired setpoint, the temperature switch can trigger the cooling system to prevent overheating.

Contact temperature sensor and temperature switch

A contact temperature sensor can monitor the temperature of refrigerant lines in an HVAC system. If the sensor detects that the refrigerant temperature falls below a safe threshold, a temperature switch can deactivate the compressor to prevent freezing and potential damage.

Thermostat and various temperature sensors

A thermostat receives input from various temperature sensors to adjust indoor climate settings dynamically. During a cold winter day, an outdoor temperature sensor can signal the thermostat to preheat the building before occupants arrive, ensuring comfort while optimizing energy usage. Thermostats can also be integrated with immersion sensors to monitor and control the temperature of water in hydronic heating systems, providing precise control of water flow and temperature.