Three-Way Hydraulic Ball Valve Use Cases

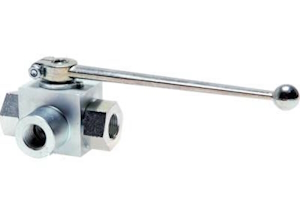

Figure 1: A 3-way hydraulic ball valve

3-way hydraulic ball valves have T-port and L-port designs which enable precise hydraulic control at pressures up to 500 bar (7252 psi).

Like any ball valve, three-way hydraulic ball valves feature a spherical closure mechanism known as a ball, which rotates on an axis to control liquid flow. Three-way ball valves' main characteristic is their capability to connect three ports, allowing the diversion, mixing, or shut-off flow through various configurations, mainly T-port and L-port designs.

View our online selection of hydraulic ball valves!

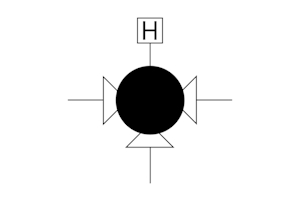

3 way ball valve hydraulic symbol

A 3-way hydraulic ball valve P&ID symbol (Figure 2) has the standard 3-way ball valve symbol with a boxed H on top to indicate that it's a hydraulic valve.

Figure 2: A 3-way hydraulic ball valve

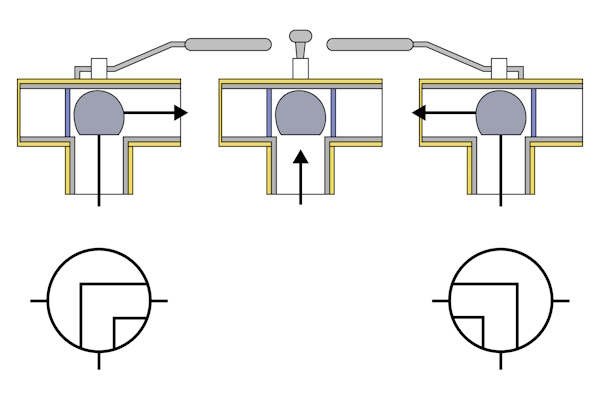

L-type hydraulic ball valves

L-type hydraulic ball valves feature an L-shaped bore, allowing fluid flow between two ports simultaneously. This configuration is ideal for systems requiring alternating flow between two outputs from a single inlet.

Figure 3: L-port hydraulic ball valves are ideal for switching hydraulic flow to two destinations from one source. Additionally, l-port ball valves can block flow.

Applications

- Excavators: For switching hydraulic flow between different actuators, such as directing fluid to the boom or the arm.

- Loaders: To select between different hydraulic circuits, such as directing fluid to either the lifting arms or the bucket tilt mechanism.

- Backhoes: For switching between the loader and backhoe functions, directing hydraulic fluid to the appropriate system.

- Agricultural equipment: For selecting between different attachments, such as directing hydraulic power to either a plow or a seeder.

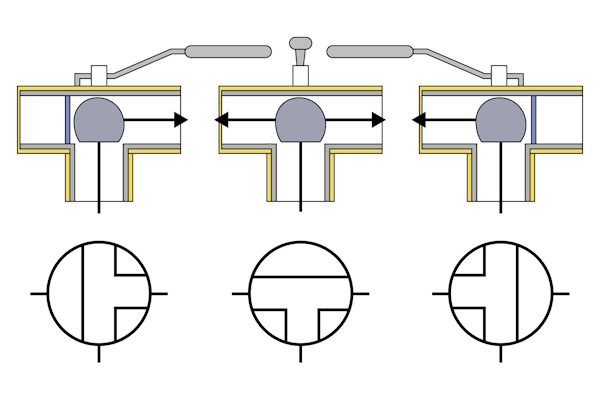

T-type hydraulic ball valves

T-port ball valves have a T-shaped bore. These valves connect all three ports simultaneously, facilitating media flow in multiple directions. They are suitable for systems that need mixing or diverting media flow. T-port valves do not have an all-ports closed position.

Figure 4: T-port ball valves can work similarly to l-port valves and additionally can send one source to two destinations simultaneously.

Applications

- Cranes: For more complex operations where fluid might need to be distributed to multiple actuators simultaneously, such as extending the boom while operating the winch.

- Bulldozers: In scenarios where simultaneous control of multiple hydraulic functions is needed, such as adjusting the blade angle and height at the same time.

- Industrial presses: For mixing or diverting hydraulic fluid to different parts of the press mechanism, allowing for simultaneous operations.

- Mining equipment: Where complex flow patterns are required, such as operating multiple drills or loaders in parallel.

FAQs

What is the primary function of a three-way hydraulic ball valve?

These valves manage the direction of hydraulic fluid flow within a system by connecting three ports in various configurations.

What is the difference between L-port and T-port three-way valves?

L-port valves allow flow between two ports at a time, while T-port valves can connect all three ports simultaneously for more versatile flow options.

How do pressure ratings affect valve selection?

Pressure ratings determine the maximum operational pressure a valve can handle; correct selection ensures safety and functionality in high-pressure systems.