How Does a Backwash Water Filter Work

Figure 1: A backwash water filter used to remove sediment from a plumbing system.

A backwash water filter operates similarly to a standard water filter but has the added efficiency of self-cleaning the filter element. During standard operation, particles get stuck in the filter element, effectively removing them from the water stream. However, the filter element becomes clogged over time by the particles, which must be cleaned out. The primary advantage of a backwash water filter is that it does not need to be disassembled to clean the filter. Instead, the filter can be changed from standard to backwash operation, which cleans the filter element and sends the particles to a wastewater system. This article goes further into how these filters are designed and how they operate.

View our online selection of backwash water filters!

Purpose

A backwash water filter is installed in a plumbing system primarily to protect and improve water quality. Its purpose is to remove contaminants, particles, and impurities from the water supply, ensuring the water is clean and safe. By incorporating a backwash water filter, a plumbing system benefits from a cleaning process that maintains the efficiency and longevity of the filter media, providing a consistent supply of purified water. There are several reasons to install a backwash water filter in a plumbing system, including the following:

- Sediment removal: To eliminate particles like sand, silt, and rust that can clog pipes and damage appliances.

- Taste and odor improvement: To remove substances like chlorine that affect water's taste and smell.

- Iron and manganese reduction: To prevent staining of fixtures and laundry, and to avoid metallic taste.

- Scale prevention: To protect pipes and appliances from scale buildup and improve water heater efficiency.

- Chemical contaminant filtration: To filter out harmful chemicals that may pose health risks.

- Water clarity: To ensure clear water, free from cloudiness and particulates.

- Maintenance of water pressure: To prevent blockages that can reduce flow and water pressure.

- Longevity of plumbing system: To extend the plumbing system's life by reducing wear from contaminants.

- Compliance with health standards: To meet regulatory standards for water quality in certain industries or applications.

Backwash water filter design

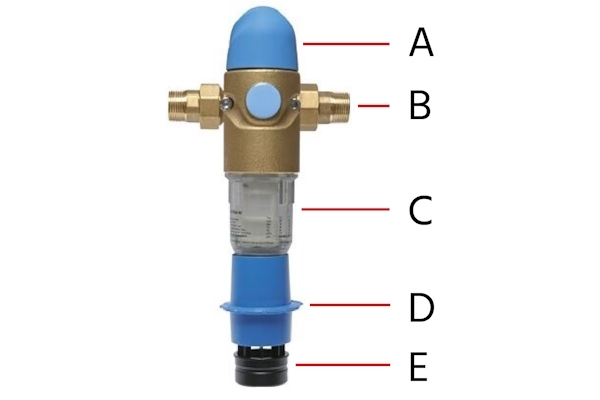

Figure 2: Backwash water filter design: knob for backwash operation (A), connection for pressure gauge and/or pipes (B), transparent bowl with filter element (C), date ring for backwash reminder (D), and HT connection for backwash (E).

Backwash water filters of different brands do not have a universal design, but some design elements, as seen in Figure 2, are typical:

- Knob for backwash operation (A): This rotational knob can be turned counterclockwise to open the backwash filter to begin backwashing.

- Connection for pressure gauge and/or pipes (B): This connection point, typically threaded, can fit directly to the piping system or mount a pressure gauge.

- Transparent bowl with filter element (C): An operator can view the filter element directly, ensuring it is seated correctly before operation.

- Date ring for backwash reminder (D): After a backwash, an operator can adjust this date ring to remind when the next backwash should occur.

- HT connection for backwash (E): An HT connection (high-torque connection) can resist twisting forces during operation. A hose or pipe can connect to the filter here to transport backwash to a basin or sewer.

Backwash water filter operating principle

A backwash water filter can operate automatically or manually, depending on the model. During standard operation, referred to as the service position, water flows into the filter and is directed through the filter element, which captures particles within the water. Purified water then flows out of the filter.

With a manual backwash water filter, the knob that operates the backwash process turns to open the HT connection and flip the filter element. Now, water flows from the inlet, through the flipped filter element, and out of the wastewater port at the bottom of the backwash water filter. Finally, this process pushes and pulls any particles stuck in the filter element, effectively cleaning it. Turning the operation knob in the opposite direction returns the backwash filter to standard operation.

Proper use of a backwash water filter

Different designs and models of backwash water filters will have specific instructions on how to use them properly. However, in general, it's important to understand the following in order to optimize the backwash filter's operation:

- Installation

- Backwash frequency

- Maintenance

Installation

-

Ensure compliance with:

- Local installation codes

- Universal guidelines

- Sanitary standards

- Technical specifications

-

Wastewater system requirements:

- Minimum diameter capable of accommodating the volume of flush water

- Example: DN 50 HT connection for a backwash water filter should connect to a wastewater system with a minimum diameter of DN 40

-

Backwash water filter specifications:

- Maximum particle size it can handle

- Installation of a coarse grain strainer (e.g., y-strainer or t-strainer) upstream if water contains coarser particles

-

Installation site conditions:

- Protection from freezing temperatures

- Shielding from disruptive elements such as solvent fumes, heating oil, detergent solutions, all types of chemicals, UV exposure, heat sources exceeding 40 °C.

-

Plastic components care:

- Avoid contact with oils, greases, solvents, and cleaning agents that are acidic or alkaline

-

Handling of plastic parts:

- Replace plastic parts after severe impacts or collisions, regardless of visible damage, due to potential for rupture

Backwash frequency

Conduct the backwash operation according to the manufacturer's instructions. In general, there are two reasons to conduct the operation:

- An appropriate amount of time has passed since the last operation (e.g., one or two months)

- The pressure drop through the filter has increased to a certain level

Maintenance

While not necessary, it's typical for a backwash water filter to be used in drinking water systems. In this case, it's essential that any maintenance on the filter is carried out by qualified personnel. DIN 1988 is an accepted standard for personnel to follow when doing maintenance on a backwash water filter.

Maintenance is typically performed to replace filter components that wear over time. The exact frequency of part replacement will be detailed in the filter's product data sheets. The sealing element for the filter element will be replaced most often, whereas o-rings and the transparent cylinder will be replaced least often.

The following instructions are for replacing the sealing element that seals the filter element within the backwash filter:

- Close the shut-off valves located before and after the filter, and place a collection container beneath if needed.

- Depressurize the filter by turning the knob counterclockwise, which opens the HT connection to the wastewater system.

- Unscrew the transparent cylinder by hand and remove it by pulling it down straight.

- Remove the filter element.

- Replace the seals and lightly moisten all seals prior to reinstallation.

- Clean the filter element with water and inspect the filter mesh for any damage, replacing it if necessary.

- Reinstall the filter element.

- Reattach the transparent cylinder to the head part and secure it by hand-tightening.

- Reopen the shut-off valves before and after the unit.

- Vent the pipeline through the closest water tap downstream of the unit and let the initial water flow out.

- Perform a visual inspection to check all connections for leaks.

- Execute a backwashing procedure.

FAQs

What is a backwash water filter?

A backwash water filter is a water filter with a backwash function that quickly cleans the filter's filter element, either manually or automatically.

How often should you backwash a water filter?

Backwash a water filter according to the manufacturer's recommendations. This process is typically done once every 1 or 2 months.