Burkert 6240 Solenoid Valve - How They Work

Figure 1: Bürkert Type 6240 Solenoid Valve

The Bürkert valve type 6240 is a 2/2-way semi-direct operated solenoid valve with a compact design and internal orifice diameters of up to DN 13. The special fluidic form of the valve body allows for high flow rates while the semi-direct operation makes it suitable for applications where zero differential pressure occurs in the system. Semi-direct operation is also referred to as servo assisted operation. The 6240 makes use of a piston instead of the typical rubber membrane, which makes the valve suitable for more demanding circumstances. The spring coupling of the pilot valve to the piston of the main valve allows for gentle opening and closing of the valve, which provides for a long service life.

This 2/2-way piston valve includes a variety of certifications and a diverse range of tested body and seal materials. This, along with specialty versions such as high-pressure, explosion protection and steam, allow for employment of the type 6240 in various applications.

Table of contents

- Is the Bürkert 6240 the right valve for you?

- Operating principle and design

- Approvals for the 6240 valves

- Features

- Special versions

- Applications

Buy Bürkert 6240 online now!

Is the Bürkert 6240 the right valve for you?

The type 6240 solenoid valve is a widely applicable valve designed for operation with no minimum differential pressure. Therefore, in a close circuit or a gravity fed system, the Bürkert type 6240 is an ideal option. The Bürkert 6240 might be the right choice for your application if:

- Your process media is a neutral gas, steam, drinking water, a hot liquid, etc. (select the proper housing and sealing material for your medium)

- Little or no differential pressure is present for opening and closing

- The valve is going to be used in a potentially explosive environment

- The valve is going to be used as an automatic shut-off valve for gas burners

- Your system media experiences high pressures and/or high temperatures

Operating principle and design

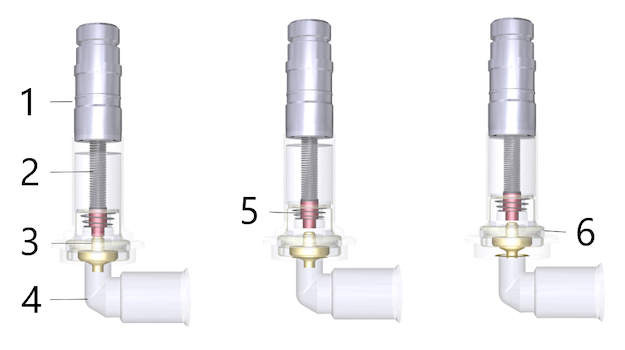

The Bürkert type 6240 is a semi-direct operated solenoid valve . Figure 2 shows the main operating components of the type 6240, minus the electric coil.

In the de-energised state, the piston sits on the main valve seat. In this state, the chamber above the piston is filled with media which is connected to the inlet and therefore applies pressure over the piston. Media pressure along with the coupling springs keep the piston sealed on the main valve seat, and prevents media flow through the orifice.

When the coil is energised, the plunger moves upwards. The plunger pulls the piston away from the main valve’s seat with the help of the coupling spring. At this point, the medium can flow through. At the same time, the coupling spring allows a small opening between the plunger and the piston. This opens the pilot port in the piston. When this pilot valve opens, the upper chamber is drained to the outlet. This results in a pressure drop over the piston, which causes the piston to move away from the main valve seat and assist the opening of the valve. . The semi-direct mechanism of the type 6240 allows for smooth, impact-free opening and closing of the valve at high pressures, but also at zero bar pressure differential.

Since the pilot valve alone can open the valve, unlike other pilot-controlled valves, Bürkert type 6240 can operate with zero differential pressure.

Figure 2: Operation of type 6240 valve showing the de-energised state (left), energised state pilot valve opens (middle), and energised state piston moving away from main valve seat (right): pilot valve (1), coupling spring (2), piston (3), valve body (4), pilot valve armature (5), and fixed coupling (6).

Approvals for the 6240 valves

This valve type is available with the below listed approvals:

- UL: Underwriters Laboratories inspects and certifies products with respect to their safety

- CE ATEX: ATEX covers devices and protective systems that will be used in explosion-prone areas (Europe)

- IECEx: IECEx covers devices and protective systems that will be used in explosion-prone areas. This certification is mandatory in Australia and New Zealand, but is also recognised in China, Japan, Korea, Brazil, etc.

- DVGW: DVGW is a European certification of devices in gas and water applications. DVGW Gas EN 161 provides certification for automatic shut-off valves to be used for gas burners and gas appliances.

- FDA: The USA Food and Drug Administration

- KTW W270: The KTW guideline is the approval of plastics and other non-metallic materials (e.g. sealing materials) for use with potable water in Germany.

- Oxygen compatibility (BAM): BAM tests the sealing material compatibility for use in flanged connections with liquid and gaseous oxygen.

Figure 3: Approvals list

Features

Material selection

Available housing materials for the type 6240 solenoid valve are brass and stainless steel (1.4305). Various types of seal material for seat seal and external seal are also available for diverse media applications:

Standard version options (seat seal/external seal):

- FKM/FKM: for medium temperature -10°C to +140°C

- EPDM/EPDM: for medium temperature -30°C to +120°C

- PTFE/FKM: for high pressure applications for medium temperature -10°C to +140°C

Additional material available for special versions of the type 6240. For more information on chemical resistance of materials please view Tamesons chemical resistance chart.

Port size range

The valve is available with a port connection of G 1/4, 3/8, and 1/2. The table below shows the corresponding orifice sizes, Kv-values, and pressure range. The Kv-value indicates the flow rate of water in 1 m3 per hour with a pressure drop of 1 bar. Correct valve sizing is important to guarantee good performance of your system and also to optimize costs. Use our valve sizing calculator to quickly determine the right valve size.

Table 1: Orifice size and Kv values of Burkert 6240 solenoid valve| Port size (BSP) | Orifice (mm) | Kv (1 m3/h) | Pressure (bar) |

| G 1/4" | 6.0 | 0.6 | 0-16 |

| G 3/8" | 6.0 | 0.6 | 0-16 |

| G 1/2" | 12.0 | 2.2 | 0-16 |

Special versions

Electric power reduction

Connector plugs are available for the Bürkert 6240 that feature an integrated power reduction (kick and drop electronics). Just after the valve opens, the electric power is reduced far enough that the valve remains open, but conserves energy.

DIN EN 161 version

The Bürkert type 6240 has a special version that can be used as the automatic shut-off valve for gas burners and gas appliances. The seat seal and external seal in this version are NBR which makes it suitable for media temperatures of -10°C to +80°C. This version is available in both brass and stainless steel body.

Steam version

The steam version of the Bürkert valve 6240 has an orifice size of 13 mm and is available in stainless steel 1.4408. The seat seal and external seal in this version are both FKM, which makes it suitable for media temperatures of 0°C to 140°C. It has a pressure range of 0-4bar.

High temperature version

The high temperature version is available in DN 6 or 12 and the body is also made of stainless steel 1.4408. The seat seal and external seal in this version are PTFE and PEEK respectively, which allows for a media temperature range of -40°C to 140°C (DN 12 can go up to 180°C). The DN 6 has a pressure range of 0-16bar, but the DN 12 has an increased range of 0-25bar.

Increased pressure version for liquids and gases

For pressures slightly higher than 16bar, there is an increased pressure version. The valve body material is brass and the seat seal and external seal are made of PTFE and FKM respectively. This material combination allows for a temperatures range of -10°C to 140°C and a pressure range of 0-25bar for liquids and 0-40bar for gases with a DN of 6.

High pressure version

The Bürkert type 6240 is available in MX31 and MX32 versions designed for high pressure applications of up to 150 bar and 250 bar respectively. The body material of this version is stainless steel 1.4404 and the DN12 comes in a normally open (NO) circuit function as well. This version has a seat seal of PCTFE and external seal of FKM, which make it suitable for media temperatures of -10°C to +80°C. If a lower temperature is needed, EPDM can be used for the external seal allowing it to be used down to -30°C.

Explosion protection version

The Bürkert type 6240 is available in multiple explosion proof versions which have coils with fixed cable outlets or a junction box design. The fixed cable versions have encapsulated electrical connections for this purpose. These valves are available in standard and high-pressure versions with a variety of seal materials.

Approvals for the coils with fixed cable outlet are:

-

ATEX

- II 2G Ex mb IIC T4 Gb

- II 2D Ex mb IIIC T135°C Db

-

IECEx

- Ex mb IIC T4 Gb

- Ex mb IIC T135°C Db

Approvals for the assembly of the coil and the junction box are:

-

ATEX

- II 2G Ex eb mb IIC T4 Gb

- II 2D Ex mb tb IIIC T130°C Db

-

IECEx

- Ex eb mb IIC T4 Gb

- Ex mb tb IIC T130°C Db

Applications

The Bürkert type 6240 is especially applicable in the gases and liquids sectors including fire extinguishing and distillery systems, gas supply and water treatment facilities, as well as temperature control technology. The KTW and W270 certification makes this valve suitable for drinking water systems as well.

Due to the availability of media-resistant materials such as stainless steel and PEEK/PTFE for this valve, the type 6240 is suitable for pharmaceutical and chemical labs where a diverse range of ultra pure gases are used for analysis purposes.

The steam version of the type 6240 is ideal for applications such as washing systems, high-pressure sterilization equipment up to 6 bar, or coffee makers.