Burkert 6281 Solenoid Valve - How They Work

Figure 1: Bürkert 6281 solenoid valve size range

The Bürkert Type 6281 valve, part of the indirect-operated S.EV series, offers diverse materials and design options with various certifications, making it versatile for many applications. It is ideal for water and compressed air systems in car washes, drinking water treatment, swimming pools, heating, and refrigeration. This 2/2-way valve uses a direct-acting plunger as the pilot valve, with a flexible diaphragm sealing the main valve seat.

Table of contents

Buy Bürkert 6281 online

Is Bürkert 6281 the right valve for you?

This valve might be the right choice for your application if:

- Your medium is a neutral fluid (e.g. water and compressed air), oil and fat-free fluid, acetone or aqueous alkali solution (please refer to appropriate media per seal material).

- Your medium is drinking water or food for which you require national and international certification for media contacting materials of the valve.

- Your system has a permanent pressure differential of at least 0.2 bar and a max. differential pressure of 16 bars.

- You are looking for valves to be used in potentially explosive atmospheres.

- You are looking to control larger flow rates for pipe sizes ranging from 3/8” to 2 ½".

Approvals for the 6281 valve

This valve type is available with a wide variety of approvals. The most important are listed below:

- Drinking water KTW + W270: The KTW guideline is the approval of plastics and other non-metallic materials (e.g. sealing materials) for use with potable water in Germany.

- NSF 61 (stainless steel in preparation): United States’ certification for water treatment or distribution products

- Watermark: A certification used in relation to water supply, sewerage, plumbing and drainage goods in Australia.

- Oxygen compatibility (BAM): BAM tests the sealing material compatibility for use in flanged connections with liquid and gaseous oxygen.

- Conformity with EGV 1935/2004:: Food contact materials regulation

- ATEX:ATEX covers devices and protective systems that will be used in explosion-prone areas (Europe)

- IEC EX: International electrotechnical commission system for certification to standards relating to equipment for use in explosive atmospheres

- UL, UR: Underwriters Laboratories inspects and certifies products with respect to their safety

- CSA: The Canadian Standard Organization

Figure 2: Bürkert 6281 solenoid valve approvals

Features

Material selection

Bürkert type 6281 valves come in both brass and stainless-steel body material options. The standard brass housing satisfies all European drinking water requirements. Particularly for applications with stringent requirements for chemical resistance, stainless steel is often the best solution.

Suggested media per seal material are as follows:

- NBR: Neutral fluids, e.g. compressed air, water

- EPDM: Oil and fat-free fluids, hot water, acetone, aqueous alkali solution

- FKM: Hot air, per-solution

Design options

The following options for this solenoid valve are available upon request:

- Kick & drop electronics: used to increase the switching pressure for solenoid valves. The built-in electronics provide a high current to help opening the valve and switch to a lower holding current to keep the valve in open position. This way, power consumption and coil temperature can be significantly reduced during continuous operation.

- Pulse coil: for reduced energy consumption.

- Block assembly: the block flange of Bürkert 6281 can be mounted directly on the customer-specific fluidic components to save space. The compact design block flange is manufactured from PPS which is durable and resistant to mildly acidic and alkaline solutions.

- Dezincification-resistant brass: for Australian Watermark certification.

- Nickel-plated brass (5 µm) and stainless steel versions: for mildly acidic and alkaline solutions and ultra-pure water and drinking water.

- Free of oil, grease and silicon.

Port size range

The valve is available with port sizes from G 3/8“ up to G 2 1/2“. Table 1 shows the corresponding orifice sizes and Kv-values. The Kv-value indicates the flow rate of water in m3 per hour with a pressure drop of 1 bar. Correct valve sizing is very important to guarantee good performance of your system and also to optimize costs. Use our valve sizing calculator to quickly determine the right valve size.

Table 1: Orifice size and Kv values

| Port size (BSP) | Orifice (mm) | Kv (m3/h) | Pressure (bar) |

| G 3/8" | 13 | 3.8 | 0.2-16 |

| G 1/2" | 13 | 3.8 | 0.2-16 |

| G 3/4" | 13 | 3.8 | 0.2-16 |

| G 3/4" | 20 | 8.5 | 0.2-16 |

| G 1" | 20 | 8.5 | 0.2-16 |

| G 1" | 25 | 12 | 0.2-16 |

| G 1-1/4" | 25 | 12 | 0.2-16 |

| G 1-1/4" | 40 | 23 | 0.2-16 |

| G 1-1/2" | 40 | 30 | 0.2-16 |

| G 2" | 40 | 30 | 0.2-16 |

| G 2" | 50 | 40 | 0.2-16 |

| G 2-1/2" | 50 | 40 | 0.2-16 |

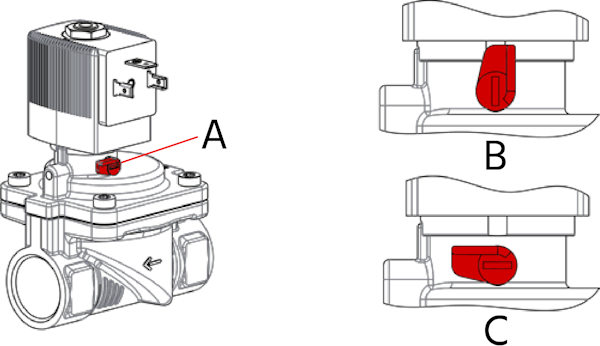

Manual override

The NC (normally closed) brass body versions of type 6281 have a manual override option available for easy maintenance and commissioning. To control the valve manually, the hand lever under the coil must be turned into the vertical position (Figure 3).

Figure 3: Manual override: hand lever (A), opened (B) and closed positions (C)

Damped design for quiet closing

The noise level during the closing of the valve depends on the inner valve contours and the diaphragm holder and the diaphragm material. Bürkert type 6281 features a damped design for noise reduction during closing of the valve.

Electric power reduction

Bürkert 6281 features two designs that provide for power reduction: Pulse coils and power reducer component in the standard connector. Both these features are available upon request.

The pulse coil provides a solution for applications with low frequency switching. Another common term for this feature is latching, or bi-stable. A short electrical pulse initiates the switching by energizing the solenoid core and an integrated permanent magnet ensures that the core is held in position. A second release winding integrated in the coil creates an opposed force which releases the core. As no electrical power is required for holding the relevant switch position, this ensures low power consumption and low heat development in the valve.

In addition to a power-reduced coil, the electrical power can be reduced using a small electronic component in the standard connector. This component makes sure that the pilot valve switches from inrush to holding power after around 350 ms

Explosion protection - ATEX versions

Explosion proof versions of this valve type are suitable for potentially explosive environments. The ATEX version of Bürkert type 6281 is for use in Zone 1. In this version of the valve, the coil is encapsulated, its cable is moulded and it is provided with an integrated suppressor circuit.

If you wish to use the valve in Zone 2, a detachable plug-type connector that complies with Cat. 3GD can be provided to you.

The ATEX ratings are:

- II 2G Ex mb IIC T4 Gb

- II 2D Ex mb IIIC T130°C Db

Applications

- Irrigation/sprinkler systems: The indirect operated 6281 solenoid valve is a reliable and cost-effective solution in greenhouses or open fields where pipes with process connections from ½” to 2” are used for irrigation and sprinkling. In these applications, while water pressure is between 2 and 6 bars, the free outlet of the pipe achieves a constant sufficient differential pressure.

- Drinking water and foods: Bürkert 6281 fulfils the requirements of stringent national and international requirements for media contacting materials of valves with extensive certifications.

- Milking parlour: The stainless-steel version of Bürkert type 6281 with the epoxy encapsulated coil is perfect for milking parlour technology where the atmosphere is somewhat aggressive due to disinfecting and cleaning agents as well as the manure from the cows.