Learn How To Cut Copper Pipe

Figure 1: A copper pipe cutter.

A copper pipe cutter is used for its precision and ease of use. Copper pipe is popular in plumbing but also for aesthetic design purposes. This article instructs on how to cut copper pipe, compares the copper pipe cutter with other tools, and discusses purchasing a pipe cutter based on the application.

Table of contents

- Copper pipes

- What is a copper pipe cutter?

- How to use a copper pipe cutter

- Cutting copper pipe without a copper pipe cutter

- Buying a copper pipe cutter

- FAQs

Check out our selection of pipe and tube processing tools!

Copper pipes

Copper pipes are not only functional in plumbing systems. As seen in Figure 2, their special appearance makes them applicable for design projects. While the list of how design projects use copper pipes is too long, there are a few notable reasons why these pipes fit well in plumbing systems.

- Antimicrobial properties: Copper and its alloys, bronze, brass, and copper-nickel, all have natural antimicrobial properties which help keep water free of harmful bacteria.

- Bendability: With the proper tools, bending copper pipe is a simple job. Each bend in a pipe system eliminates the need for an elbow to change the pipe’s direction. Fewer elbows saves money and reduces the system's total number of failure points.

- Softness: Compared to steel and cast iron, copper pipe is soft. This means copper pipe is easy to cut through to accomplish the needs of a project.

Figure 2: A low-light ambiance project uses copper pipes and fittings to enhance a room’s atmosphere.

What is a copper pipe cutter?

A copper pipe cutter is a manual tool that precisely and squarely cuts copper pipe. Like all pipe cutters, a typical copper pipe cutter has a C-shaped head and a handle. As seen in Figure 3, some copper pipe cutters do not have a handle, allowing for cutting copper pipes in smaller spaces.

Figure 3: A copper pipe cutter without a handle allows for pipe cutting in tighter spaces.

A copper pipe cutter’s components that work to cut a copper pipe are:

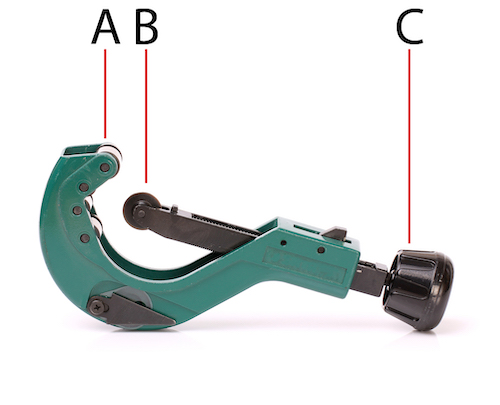

- Rollers: The rollers (Figure 4 labeled A) spin as they move across the pipe’s surface. This prevents the pipe cutter from turning the pipe during operation.

- Cutting blade: Made of hardened steel, the cutting blade (Figure 2 labeled B) cuts into the pipe during operation.

- Tightening knob: The tightening knob (Figure 2 labeled C) pushes the cutting blade forward. This initially clamps the copper pipe cutter onto the pipe and progressively deepens the cut during operation.

Figure 4: A copper pipe cutter with components: rollers (A), cutting blade (B), and tightening knob (C).

What is a copper tube cutter?

A copper tubing cutter is the same tool as a copper pipe cutter. These tools have different names because of the differences between tubes and pipes. A tube’s diameter is the outside diameter of the pipe, whereas a pipe’s diameter is the inside diameter. Also, tubes come in different shapes, including round. Pipes are only round.

How to use a copper pipe cutter

Copper pipe cutting with a copper pipe cutter is straightforward. However, there are some points to pay attention to before and after cutting.

Before using a copper pipe cutter

The plan for cutting through a copper pipe depends on whether the pipe is in situ (already installed) or a piece of pipe not currently in use.

-

In situ:

- Shut off the source of fluid to the pipe. Anticipate that there will be some leakage as the pipe is cut open.

- Determine whether there is enough space to use a copper pipe cutter with or without a handle. If there is not enough space, consider using a different tool (see the section below about cutting copper pipe without a pipe cutter).

-

Independent piece of copper pipe

- Clamp the copper pipe to a workbench to stabilize it during the cutting process.

Also, before cutting, put on the proper personal protective equipment (PPE):

- Gloves: Gloves protect hands from any stray copper shavings that may fly through the air.

- Safety glasses: Safety glasses protect eyes from the same danger.

Using a copper pipe cutter

To cut copper pipe with a copper cutting tool, follow these instructions:

- Clamp the copper pipe cutter to the copper pipe by turning the tightening knob until the cutting blade touches the pipe’s surface.

- Turn the copper pipe cutter entirely around the pipe one or two times to create a groove in the pipe’s surface.

- Turn the tightening knob to push the cutting blade forward and tighten the clamp.

- Repeat this turning and tightening process until the cut is complete.

After using a copper pipe cutter

Although a copper pipe cutter provides a cleaner cut than all other cutting tools, it is still possible that the cut edge of the pipe will have burrs. Use a deburring tool to remove the burrs and sandpaper to smoothen the edge.

Cutting copper pipe without a copper pipe cutter

If a copper pipe cutting tool is unavailable, there are still several different tools for cutting copper pipe. Most of the tools are power saws, but there are two notable manual tools: the hacksaw and the auto cut tool. No matter which tool cuts through the copper pipe, remember to deburr and smooth the end of the cut pipe after cutting.

- Hacksaw: When using a hacksaw to cut copper pipe, choose a 32 TPI (teeth-per-inch) blade. Blades with lower TPI have more space between the blade teeth, which makes it easier for the blade to get clogged on the pipe. Hacksaws cause a lot of vibration and movement, so it is unlikely to cut in situ pipes well. Learn more by reading our articles about how to use a hacksaw and hacksaw blade selection.

- Auto cut tool: An auto cut tool functions similarly to a pipe cutting tool, meaning it spins around the pipe to create the cut. However, the tool is circular in shape. One part of the tool opens so the pipe can fit inside of it. This tool can fit into any space that has about 1.3 cm (0.5 in) of space behind the pipe. However, it is non-adjustable, so ensure the tool is the right size for the pipe that will be cut.

Among power saws, there are several types suitable for cutting copper pipe. Wearing gloves and safety glasses is necessary. A mask can protect lungs from copper shavings.

- Dremel: Ensure the copper pipe is secure in a vice or clamp. Choose a metal cutting blade for the dremel. If used to cut metal, blades for softer materials will wear down quickly. Cut in a circular motion around the pipe.

- Multi-tool: The multi-tool blade, which should be a metal cutting blade, oscillates rapidly. During operation, push the tool forward as it cuts through the pipe. The greatest benefit to using a multi-tool to cut copper pipe is that this tool can cut very close to a wall.

- Chop saw: Ensure the saw’s blade is metal cutting and the pipe is secure in a clamp. Next, ensure that the blade operates at full speed before encountering the pipe. The benefit of using a chop saw is that it can make cuts perfectly 90°. One downside is that the saw operates so efficiently that users sometimes get careless and make mistakes.

- Sawzall: Also known as a reciprocating saw, a Sawzall can quickly cut through copper pipe with the correct metal blade attachment. However, Sawzalls are not accurate and are best for demolition work.

- Jigsaw: Like Sawzalls, Jigsaws are best for demolition jobs.

Battery operated copper pipe cutter

An electric solution to cutting copper pipe, which is not a power tool, is the battery operated copper pipe cutter. This electric copper pipe cutter operates similarly to a manual copper pipe cutter, except that the user pulls a trigger to spin the cutting blade around the pipe rather than turning the entire tool. The cutting blade automatically pushes forward as the cut deepens. This operation saves greatly on a user’s wrists, which can become fatigued after extensive manual pipe cutting.

Besides its higher price, the downside of an electric pipe cutter is that it is significantly wider than its manual counterpart. Therefore, it cannot fit into as many spaces as a manual tool can.

Buying a copper pipe cutter

When buying a copper pipe cutter, the controlling factor is the amount of space available for cutting. If the copper pipe is not in situ, buy the largest copper pipe cutter. The longer the handle of the cutter, the more leverage there is during cutting. However, take care that the pipe cutter is for copper and not steel. Steel pipe cutters have harder and thicker blades that are not appropriate for cutting copper.

For cutting through in situ copper pipes, first determine the orientation the copper pipe cutter will have during cutting. Then, determine how much space will be necessary to move the tool completely around the pipe. If there is not enough space for a standard copper pipe cutter that has a handle, determine if there is enough space for a cutter that does not have a handle.

FAQs

What’s the best way to cut copper pipe?

The best way to cut copper pipe is with a copper pipe cutter. This tool safely and accurately cuts through copper pipe, leaving a nearly smooth finish.

Is it OK to cut copper pipe with a hacksaw?

Yes, it’s OK to cut copper pipe with a hacksaw. However, it’s not so easy to cut through copper pipe that is installed in a plumbing system already. The easiest application is independent copper pipes that are clamped to a workstation for stability and safety.

How to cut a copper pipe in a tight space?

First, determine if there is enough space for a handleless copper pipe cutter to fit in the space. If not, try with an auto cut tool. If neither option works, an oscillating multi-tool might be able to get the job done.