Learn How Hydraulic Jacks Work

Figure 1: Hydraulic jacks

In a hydraulic jack, fluid pressure amplifies force within a cylinder to elevate a heavy load. These jacks are used in various fields, including machine shops, the automotive industry, material handling equipment, lifting platforms, railroad maintenance, and hydropower plants. This article explores the functioning of hydraulic jacks, proper usage techniques, the various types available, and key factors to consider when choosing a hydraulic jack.

Table of contents

- Hydraulic jack operating principle

- Components of a hydraulic jack

- How to use a hydraulic jack

- Types of hydraulic jacks

- Selection criteria

- Safety

- FAQs

View our online selection of hydraulic jacks!

Hydraulic jack operating principle

Hydraulic jacks operate based on Pascal's Law. This law states that a pressure change at one point in an enclosed incompressible fluid leads to the exact pressure change at every point. This law also governs the hydraulic jack press and the braking system for most vehicles. According to the law, pressure equals force divided by area. Therefore, force equals pressure multiplied by area. If pressure is constant and area increases, force also increases.

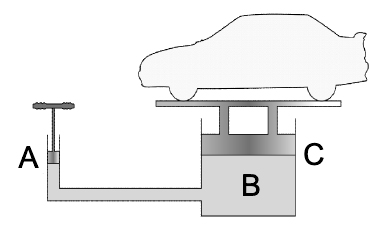

Figure 2: The principle of hydraulic lifting devices (Pascal's Law): a small force (A), incompressible fluid (B), and a large lifting force (C).

Figure 2 illustrates Pascal's Law and how hydraulic jacks work. A person operates the lever to push down the plunger piston (Figure 2 labeled A). This downward movement creates a change in pressure. The fluid in the larger hydraulic cylinder (Figure 2 labeled B) equally changes in pressure, applying it to the ram piston (Figure 2 labeled C). Since pressure is the ratio of force to area, the ram piston's larger surface area will distribute a larger lifting force. The larger force lifts the load above the ram cylinder. To raise the load to a reasonable height, the plunger piston has to move a greater distance than ram piston.

Example

A hydraulic jack with a piston-to-piston area ratio of 1:100 lifts a 1.5-ton car. The car exerts a force of approximately 15000 N on the ram piston. However, the plunger piston only requires 150 N of force to push down. The plunger piston must move down 100 cm for every 1 cm that the ram piston rises. This movement is possible because of a cycle operation involving a reservoir and a check valve (not shown in Figure 2).

Components of a hydraulic jack

There are seven primary hydraulic jack parts:

- Reservoir: The reservoir stores the hydraulic fluid for a change in pressure.

- Plunger piston: The plunger piston pushes the hydraulic fluid from the reservoir through a check valve to the ram cylinder.

- Check valve: The check valve prevents fluid return from the ram cylinder to the plunger cylinder. Therefore, the ram cylinder maintains the rising pressure.

- Ram cylinder: The ram cylinder transfers the pressure of the hydraulic fluid to the ram piston.

- Ram piston: The ram piston lifts the load.

- Release valve: The hydraulic jack release valve returns pressurized fluid to the reservoir.

- Handle: The hydraulic jack handle provides leverage to operate the plunger piston easily.

The ANSI/ASME B30 standard contains recommendations and regulations for the construction, installation, operation, inspection, testing, maintenance, and use of lifting machines such as hydraulic jacks.

How to use a hydraulic jack

Using a hydraulic jack correctly depends on the specific application. This section details the similarities between using a hydraulic jack in any situation.

- Before: There are important considerations to make before using a hydraulic jack.

- Ensure the jack is on level ground.

- Check the jack for any damage or leaking.

- Prepare jack stands to hold the load’s weight after lifting.

- During:

- Insert the handle into the plunger piston’s socket to pump the jack and raise the load to the desired height.

- Ensure the ram piston contacts the load at a proper lift point. For example, the axle of a vehicle.

- Insert the jack stands beneath the load next to the hydraulic jack and lower the load’s weight onto the jack stands.

- Perform any necessary work.

- Use the hydraulic jack to lift the load once again and remove the jack stands.

- Open the hydraulic release valve to lower the load slowly.

Types of hydraulic jacks

Hydraulic bottle jack

A hydraulic bottle jack, or whiskey jack, has a bottle shape and is a compact hydraulic jack. It has a vertical lifting ram with a support pad at the top. A small reservoir supplies hydraulic fluid to the main cylinder beneath the ram. By interconnecting and evenly distributing multiple bottle jacks across the base of a load, bottle jacks can form a vertical hydraulic jack system for lifting heavy objects with a broad base, such as a house. A bottle jack is light enough to hold and operate as a horizontal hydraulic jack.

Hydraulic floor jack

The hydraulic floor jack, or trolley jack, consists of a horizontal ram piston pushing the short end of a bell crank. The bell crank’s long arm connects to the lift pad, providing vertical motion of the load. The horizontal cylinder and piston allow the floor jack to operate with a low profile. The caster wheels on the base provide easy maneuvering under a load.

Figure 3: Hydraulic floor jack

Hydraulic scissor jack

Scissor jacks cannot hold as much weight or lift as high as floor jacks. Therefore, these jacks are only suitable for lifting a vehicle to change a tire. However, they are compact and easily fit in any vehicle’s trunk. The hydraulic scissor jack is much easier to operate than its manual counterpart.

Hydraulic transmission jack

A hydraulic transmission jack’s function is specifically for a car’s transmission. The jack has a vertical ram piston with a wide frame on top. The frame clamps onto the transmission to lower it from the vehicle or raise it back up to the vehicle. Hydraulic transmission jacks are necessary tools for any vehicle repair shop.

Selection criteria

There are several specifications of a hydraulic jack to consider when deciding which is best for an application. Here are some useful guidelines:

- Load capacity: The lifting load capacity is the most crucial parameter.

- Clearance: Check to see that the hydraulic jack can fit under the load. The hydraulic floor jack, for example, offers a low profile.

- Lift height: Determine that the jack can lift high enough to perform the necessary work.

- Automatic or manual: Hydraulic jacks can be automatic or manual. Manual hydraulic jacks use hand power, and automatic hydraulic jacks utilize air or electric power. However, the operating principle is the same.

- Application: The design of some hydraulic jacks is explicitly for specific industrial functions, e.g., hydraulic jacks used for splitting logs of wood. Check to ensure it can work for the intended purpose.

Safety

The correct use of equipment such as hydraulic jacks is important. Consider the following in addition to the selection criteria:

- Do not exceed the maximum lifting weight in tons. Overloading can damage the cylinder casing or cause leakage of the hydraulic fluid. However, the design of some hydraulic jacks has an overload valve if maximum pressure is exceeded.

- There must always be sufficient oil in the reservoir. Otherwise, the maximum pressure of the hydraulic jack will not be reached.

- A leakage in the cylinder during operation can lead to a fatal accident. Check the manufacturer’s instructions on preventive maintenance.

FAQs

How does a hydraulic jack work?

A user pumps a hydraulic jack’s handle to move hydraulic fluid from one cylinder to a larger cylinder. According to Pascal’s Law, this allows the small force from the handle to transfer into a larger force at the lifting end of the jack.

Do jacks use hydraulic power?

Many jacks found in repair shops and home garages use hydraulic power. That being said, manual, electric, and air jacks can also be used.