Hydraulic Pumps - How They Work

Figure 1: Hand-powered hydraulic pumps

A hydraulic pump converts mechanical energy into fluid power. It's used in hydraulic systems to perform work, such as lifting heavy loads in excavators or jacks to being used in hydraulic splitters. This article focuses on how hydraulic pumps operate, different types of hydraulic pumps, and their applications.

Table of contents

- How does a hydraulic pump work?

- Types of hydraulic pumps

- Common applications

- Selection criteria

- FAQs

View our online selection of hydraulic pumps!

How does a hydraulic pump work?

Figure 2: Air-powered hydraulic pumps

A hydraulic pump operates on positive displacement, where a confined fluid is subjected to pressure using a reciprocating or rotary action. The pump's driving force is supplied by a prime mover, such as an electric motor, internal combustion engine, human labor (Figure 1), or compressed air (Figure 2), which drives the impeller, gear (Figure 3), or vane to create a flow of fluid within the pump's housing.

A hydraulic pump’s mechanical action creates a vacuum at the pump’s inlet, which allows atmospheric pressure to force fluid into the pump. The drawn in fluid creates a vacuum at the inlet chamber, which allows the fluid to then be forced towards the outlet at a high pressure.

The different types of pumps (i.e., gear, vane, and piston) utilize different mechanisms to create fluid flow and pressure.

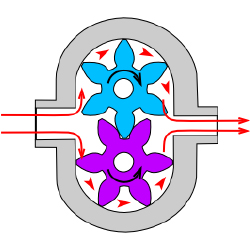

- Gear pump: Two meshing gears rotate in opposite directions, creating chambers that expand and contract, which generates fluid flow and pressure.

- Vane pump: Vanes are pushed outwards by centrifugal force and pushed back into the rotor as they move past the pump inlet and outlet, generating fluid flow and pressure.

- Piston pump: A piston is moved back and forth within a cylinder, creating chambers of varying size that draw in and compress fluid, generating fluid flow and pressure.

A hydraulic pump's performance is determined by the size and shape of the pump's internal chambers, the speed at which the pump operates, and the power supplied to the pump. Hydraulic pumps use an incompressible fluid, usually petroleum oil or a food-safe alternative, as the working fluid. The fluid must have lubrication properties and be able to operate at high temperatures. The type of fluid used may depend on safety requirements, such as fire resistance or food preparation.

Figure 3: A gear pump illustration. Gear pumps are used in hydraulic systems.

Types of hydraulic pumps

There are many types of hydraulic pumps. They can fit into the following categories:

- Power source based

- Pump action based

- Positive displacement types

Power source

Based on the power source, different types of hydraulic pumps are:

- Air hydraulic pump: These pumps have a compact design and do not require an external power source. However, a reliable source of compressed air is necessary and is limited by the supply pressure of compressed air.

- Electric hydraulic pump: They have a reliable and efficient power source and can be easily integrated into existing systems. However, these pumps require a constant power source, may be affected by power outages, and require additional electrical safety measures. Also, they have a higher upfront cost than other pump types.

- Gas-powered hydraulic pump: Gas-powered pumps are portable hydraulic pumps which are easy to use in outdoor and remote environments. However, they are limited by fuel supply, have higher emissions compared to other hydraulic pumps, and the fuel systems require regular maintenance.

-

Manual hydraulic pump: They are easy to transport and do not require a power source. However, they are limited by the operator’s physical ability, have a lower flow rate than other hydraulic pump types, and may require extra time to complete tasks.

- Hydraulic hand pump: Hydraulic hand pumps are suitable for small-scale, and low-pressure applications and typically cost less than hydraulic foot pumps.

- Hydraulic foot pump: Hydraulic foot pumps are suitable for heavy-duty and high-pressure applications and require less effort than hydraulic hand pumps.

Figure 4: Hydraulic foot pump system

Pump action based

Hydraulic pumps can be single-acting or double-acting. Single-acting pumps have a single port that hydraulic fluid enters to extend the pump’s cylinder. Double-acting pumps have two ports, one for extending the cylinder and one for retracting the cylinder.

Working principles

- Single-acting: With single-acting hydraulic pumps, the cylinder extends when hydraulic fluid enters it. The cylinder will retract with a spring, with gravity, or from the load.

- Double-acting: With double-acting hydraulic pumps, the cylinder retracts when hydraulic fluid enters the top port. The cylinder goes back to its starting position.

Applications

- Single-acting: Single-acting hydraulic pumps are suitable for simple applications that only need linear movement in one direction. For example, such as lifting an object or pressing a load.

- Double-acting: Double-acting hydraulic pumps are for applications that need precise linear movement in two directions, such as elevators and forklifts.

Positive displacement types

The three types of positive displacement mechanisms are gear, vane, and piston.

- Pressure: Hydraulic gear pumps and hydraulic vane pumps are suitable for low-pressure applications, and hydraulic piston pumps are suitable for high-pressure applications.

- Cost: Gear pumps are the least expensive to purchase and maintain, whereas piston pumps are the most expensive. Vane pumps land somewhere between the other two in cost.

- Efficiency: Gear pumps are the least efficient. They typically have 80% efficiency, meaning 10 mechanical horsepower turns into 8 hydraulic horsepower. Vane pumps are more efficient than gear pumps, and piston pumps are the most efficient with up to 95% efficiency.

Common applications

Hydraulic pumps have a wide range of applications in different industries.

- Automotive industry: In the automotive industry, hydraulic pumps are combined with jacks and engine hoists for lifting vehicles, platforms, heavy loads, and pulling engines.

- Mechanical workshops: In mechanical workshops, hydraulic pumps power tools for applications such as cutting, drilling, pressing, and pulling.

- Wood workshops: In wood workshops, hydraulic jacks are used in splitters.

- Process and manufacturing: Heavy-duty hydraulic pumps are used for driving and tapping applications, turning heavy valves, tightening, and expanding applications.

- Heavy machinery: Hydraulic pumps are used in heavy machines such as excavators, cranes, loaders, and tractors.

- Production facilities: Hydraulic pumps are also used in conveyors, mixers, and forklifts.

Figure 5: Hydraulic pump applications

Selection criteria

Despite the different pump mechanism types in hydraulic pumps, they are categorized based on size (pressure output) and driving force (manual, air, electric, and fuel-powered). There are several parameters to consider while selecting the right hydraulic pump for an application. The most important parameters are described below:

- Operating pressure: Consider the system’s maximum operating pressure and the minimum pressure to generate the required force against the load.

- Source of driving force: Is it to be manually operated (by hand or foot), air from a compressor, electrical power, or a fuel engine as a prime mover? Other factors that may affect the driving force type are whether it will be remotely operated or not, speed of operation, and load requirement.

- Speed of operation: If it is a manual hydraulic pump, should it be a single-speed or double-speed? How much volume of fluid per handle stroke? When using a powered hydraulic pump, how much volume per minute? Air, gas, and electric-powered hydraulic pumps are useful for high-volume flows.

- Portability: Manual hand hydraulic pumps are usually portable but with lower output, while fuel power has high-output pressure but stationary for remote operations in places without electricity. Electric hydraulic pumps can be both mobile and stationary, as well as air hydraulic pumps. Air hydraulic pumps require compressed air at the operation site.

- Operating temperature: The application operating temperature can affect the size of the oil reservoir needed, the type of fluid, and the materials used for the pump components. The oil is the operating fluid but also serves as a cooling liquid in heavy-duty hydraulic pumps.

- Displacement of load: How much travel the load requires will affect the oil reservoir size and number of cylinders in the hydraulic pump.

- Operating noise: Consider if the environment has a noise requirement. A hydraulic pump with a fuel engine will generate a higher noise than an electric hydraulic pump of the same size.

- Spark-free: Should the hydraulic pump be spark-free due to a possible explosive environment? Remember, most operating fluids are derivatives of petroleum oil, but there are spark-free options.

FAQs

What is a hydraulic pump?

A hydraulic pump transforms mechanical energy into fluid energy. A relatively low amount of input power can turn into a large amount of output power for lifting heavy loads.

How does a hydraulic pump work?

A hydraulic pump works by using mechanical energy to pressurize fluid in a closed system. This pressurized fluid is then used to drive machinery such as excavators, presses, and lifts.

What is a hydraulic ram pump?

A hydraulic ram pump leverages the energy of falling water to move water to a higher height without the usage of external power. It is made up of a valve, a pressure chamber, and inlet and exit pipes.

What is the difference between a water pump vs a hydraulic pump?

A water pump moves water from one area to another, whereas a hydraulic pump's purpose is to overcome a pressure that is dependent on a load, like a heavy car.