Masonry Chisels

Figure 1: Using a masonry chisel to prepare a floor for new tiling.

Masonry chisels are suitable for cutting through concrete, asphalt, bricks, and mortar for demolition work. Often, these chisels pair with an air hammer to break apart hard material, whereas softer chisels for stonework require a hammer. This article takes a closer look at masonry chisels and their various applications. Read our chisel overview guide for more information about different types of chisels.

Table of contents

View our online selection of air hammers & chisels!

Masonry chisel types

Some argue that a masonry chisel is a specific type that differs from a brick chisel; others lump together multiple chisels under the name masonry or stone chisel. To avoid confusion, this section discusses these various types of chisels separately.

- Concrete chisel: Concrete chisels look similar to wood chisels because they have a beveled edge and handle. However, a harder metal, such as vanadium chromium alloy steel, is necessary for these chisels.

- Cement chisel: Cement chisel is another name for concrete chisels. A chisel of either name is suitable for cutting through concrete.

- Brick chisel: Brick chisels have a wider blade for cracking through masonry blocks rather than cutting them.

- Stone chisel: Stone chisels come in various designs for cutting and shaping stone, such as sandstone. These chisels are the most appropriate for sculptors.

- Rock chisel: A rock chisel is a special type applicable for breaking open rocks to access mineral specimens.

- Masonry chisel: Masonry chisels cut through bricks, cinder blocks, and cement blocks. Also, these chisels are suitable for removing excess mortar from a surface. The chisel in a jackhammer or air hammer is a masonry chisel.

Note: While cold chisels can cut through masonry, having specially made masonry chisels on hand is preferable.

Masonry chisels and air hammers

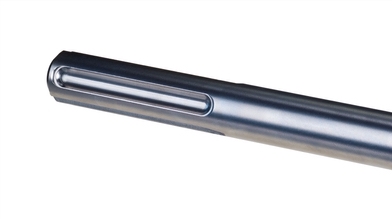

Figure 2: A masonry chisel in an air hammer.

Masonry chisels typically have slotted drive shaft (SDS) shanks or hex shanks that fit into the chuck of an air hammer. An SDS shank fits into a spring-loaded SDS chuck and does not require tightening. Due to the shank's non-circular cross-section (Figure 3), the chisel does not slip out of the chuck as it rotates and moves back and forth like the piston. A hex shank fits into a chuck with a three-toothed jaw assemblage.

Figure 3: SDS shank

Masonry chisels that fit into air hammers have a variety of head types:

- Moil: Moil chisels, also called bull points, have a sharp, tapered tip to prick and drive through brick, concrete, or slag. Clean-up and demolition tasks need moil chisels to chip, chisel, and break materials. Moreover, these masonry chisels are mostly made from strong carbon steel.

- Asphalt cutter: Asphalt cutters suit demolition and chiseling jobs. These masonry chisels are extra sharp (sharpened edges) for the faster and more precise breaking up of hard-packed gravel or asphalt.

- Carbide bushing tool: A carbide bushing tool has a cube-shaped head with many sharp points on one side. This tool can texturize concrete.

- Clay spade: A clay spade chisel looks similar to a spade shovel and is suitable for digging into clay material.

- Flexible chisel: A flexible chisel is suitable for removing soft material (e.g., carpet) from a harder surface without damaging the lower surface.

How to use a masonry chisel

The most common application for masonry chisels is flattening uneven sections of a wall by chipping away extra dry mortar and protruding bricks. They are mostly used with a sled or club hammer that's hard enough to score the brick but not shatter it. However, how to use a masonry chisel will depend on the work, the surface, and the type of chisel. Ideally, only use a chisel best suited for the specific task.

Here's a step-by-step guide to using a masonry chisel.

- Wear safety gear: Before starting, wear personal protective equipment (PPE) to protect the body against potential risks. Wear safety glasses, gloves, and a safety mask. In addition, ensure that the PPE meets the industry's safety standards and requirements.

- Holding the chisel: Hold the handle with the blade facing down. Pick up the hammer with the other hand. Ensure a firm grasp of both tools.

- Using the chisel: Position the chisel at a close angle to the wall's surface and use the hammer to strike its head.

- Chisel protruding sections: Work in thin layers and slowly eliminate the protruding surfaces. Make sure only to eliminate what is necessary.

- Chisel surplus deposits of dry mortar: Avoid breaking away the mortar beds.

Read our chisel sharpening guide for more information on how to sharpen a chisel.

FAQs

What is the use of a masonry chisel?

Masonry chisels score, trim, or shape materials like stone and brick. Therefore, choosing a masonry chisel with the appropriate shape and width for your specific task is essential.

What hammer should be used with a masonry chisel?

It's crucial to use a club or sledgehammer with a masonry chisel. Any other hammer could shatter the brick or damage the chisel.

What type of chisel removes mortar?

The plugging or fluted chisel eliminates old mortar from brickwork in a process referred to as repointing. The tool's grooved part (flute) allows any remains to be eliminated.

Will a chisel break concrete?

A jackhammer and a high-powered pointed chisel might be able to break a concrete slab if it's thicker than a few inches.