Milk & Dairy Hoses - How They Work

Milk and dairy hoses are common parts of modern dairy farms as they are used in milking machinery for harvesting milk from animals. They are also used in the dairy industry for conveying milk and dairy products from one part of the plant to another. These hoses are specially made to conform to FDA & EU standards to ensure proper sanitation, milk quality and to avoid chemical contamination. The hose material may include PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), hybrid PVC-rubber or NBR (Nitrile Rubber). The rubber inner material makes these hoses resistant to dietary oils/fats. Usually, these hoses are reinforced with coils and an abrasion resistant outer layer to ensure longevity.

Table of contents

- Requirements of a milk and dairy hose

- Special features of milk and dairy hoses

- Fittings & accessories

- Milk and dairy hose applications

Buy Milk & Dairy Hose Online Today!

Requirements of a milk and dairy hose

Design

Milk and dairy hoses are specifically designed for transporting milk and dairy products, as well as for animal and vegetable oils and fats. When hose flexibility is important, like in a milk parlor (a cow milking area), PVC hoses are generally used. A Hybrid PVC-Rubber hose increases the temperature and pressure operating range. The temperature and pressure for the hose is dependent upon the industrial requirement, application and operating environment. Generally, the service temperature of dairy and milk hoses may vary from -40°C to 120°C (-40°F to +248°F). The tube is generally white and smooth and must comply to FDA rules. To increase durability the tubes are often reinforced with stainless steel helix wire.

Standards (FDA/EU)

Milk and dairy hoses and their assemblies must meet FDA, EU and other standards for food safety and sanitation. Review your local standards to ensure compliance.

- The 21 CFR 177.2600 compliance in the FDA is concerned with the ‘Indirect Food Additives’ that may contaminate the food through the materials like transfer hoses and processing equipment. It lists the substances safe for food processing, extraction limits when in contact with fatty food and its cleansing necessity.

- FDA Grade 'A' PMO (Pasteurized Milk Ordinance) outlines the minimum sanitary standards to be practiced during the processing of milk and milk products. It states the use of smooth, nonabsorbent, corrosion resistant and nontoxic material for food-grade hoses and other equipment.

- The Commission Directive 2007/19/EC and Regulation (EC) 1935/2004 legislation in EU gives an overview on materials that may come in contact with food, approved substances and limits on migration of additional substances in onto the food.

Material considerations

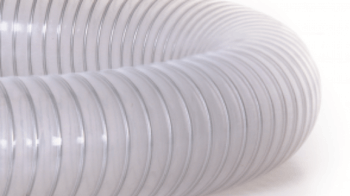

Figure 2: Stainless-steel wire reinforced hose

PVC, EPDM, hybrid PVC-rubber or NBR are generally used for food grade hose materials. However, following criteria should be considered while selecting the material for milk and dairy hoses.

- Phthalates-free: Phthalates are a group of chemicals that make plastic harder to break and flexible. The main concern in the dairy industry is that phthalates can escape into fatty foods when it comes in contact with plastic and rubber equipment. To ensure that phthalates don’t contaminate the media within the hose, good solutions are phthalates-free plasticizers, silicones or advanced synthetic rubbers.

- Food grade hoses: Dairy hoses must be a food grade hose that are made from non-toxic compounds that prevent harmful chemical reactions. They are also odorless and tasteless, which help in preserving the actual order & taste of the milk & dairy product.

- Non-metal hoses: Dairy hoses should be non-metal hoses to prevent contamination from rust and corrosion. PVC or rubber materials are used, which not only prevents the problem of contaminations, but also provides high flexibility. To ensure strength and durability of the hose, helical structured stainless-steel wires are used in these hoses. Figure 2 is an example of stainless-steel wire reinforced hose.

- Flexibility: Flexibility is important for milk and dairy hoses as they are attached to the milking machine cluster, or milking unit, in the milking parlor. This unit needs to move around properly to attach to the cow’s teats. An example can be seen in Figure 4.

Special features of a milk and dairy hose

Since milk and dairy hose must comply to FDA & EU standards, special attention is required for its maintenance. The following considerations must be taken into account during hose maintenance.

Resistant to standard cleaning agents

Milk and dairy hoses are impervious (not affected by) to standard cleaning agents like acid/alkalis and chlorine compounds. Generally, an alkaline cleaner or a chlorinated cleaner is used to clean these hoses. The alkalis, phosphates, wetting and chelating agents in alkaline cleaner dissolves milk fats, protein and carbohydrates. Additionally, the chlorine prevents the formation of films. Acid rinse is also performed to remove mineral deposits from the milk.

Sterilizing with steam

Steam is the most effective way of sterilizing dairy hoses and equipment. Ideally, the hoses will be exposed to steam for 20-30 minutes. The steam will destroy bacteria and other contaminants and the heat subsequently makes the equipment dry. The temperature and pressure of the steam, however, depends upon the material of the hose.

Fittings & accessories

To connect the hoses to additional dairy equipment, fittings are used. The specifications for fitting should be considered thoroughly to ensure perfect fabrication, no contamination and a longer service life. The fittings for food grade hoses should also meet FDA food approval. FDA approved fitting materials used in dairy industry includes:

- Type 303/302 Stainless steel

- Type 304 Stainless steel

- Type 316 Stainless steel

- EPDM

Common fitting types used are:

- Slotted nuts (Figure 3 left)

- Linear hose fittings (Figure 3 middle)

- Hose thread fittings (Figure 3 right)

Figure 3: Slotted nuts (left), linear hose fitting (middle), and a hose thread fitting (right).

Milk and dairy hose applications

Milk and dairy hoses are used in milking machines, processing equipment, and tankers, ensuring that the products are moved efficiently without contamination. Their applications include suction and delivery of milk, cream, yogurt, and other dairy goods within production facilities and during transportation from farms to processing plants. A milk, or dairy, parlor is a specific area in a dairy farm that is used to milk cows. Figure 4 shows a dairy parlor for milking cows.

Figure 4: Milk and dairy hose usage in a dairy parlor