Pressure & Suction Hoses - How They Work

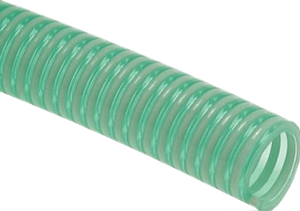

Figure 1: PVC suction-pressure hose with hard PVC support coil

Pressure and suction hoses collaborate with pumps to efficiently remove unwanted substances, like water or chemical deposits, and to transport solid materials, such as sand or wood chips. Suction hoses function under negative pressure to extract materials, whereas pressure hoses work under positive pressure to discharge materials. These hoses are constructed from various polymers, including polyvinyl chloride (PVC) and polyurethane (PU). The hose is reinforced by a support coil that runs along its length. This coil can be made from different materials, such as PVC or steel. Figure 1 depicts a light-green PVC hose with a PVC support coil running throughout the hose.

Table of contents

Buy Pressure and Suction Hose Online Today!

Examples of pressure and suction hoses

Polyvinyl Chloride suction pressure hose

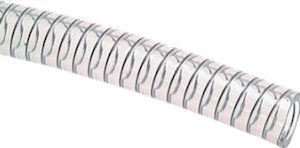

Figure 2: Flexible PVC pressure and suction hose with steel coil

A common type of industrial hose is a flexible PVC pressure and suction hose supported by a high-tensile strength spiral (Figure 2). The high-tensile strength spiral ensures that the hose does not burst under pressurized or vacuum conditions. This versatile type is capable of transporting water, compressed air, or mild acids and alkalis, including cleaning products. PVC has a low coefficient of friction, making the inner walls smooth improving flow of both liquid and solid media under high vacuum and pressure situations. This also decreases the wear and tear on the hose due to abrasion.

PVC’s versatility ranges across industries including medical, food, beverage, and energy. Generally, the working temperatures for PVC pressure and suction hoses range from -10 °C up to +65 °C. Specifically, PVC pressure and suctions hoses work well for:

- Chemical processing

- Water transport

- Waste product lines

- Viscous fluid handling

- Wet or dry food handling

- Beverage transfer

- Dairy processing

- Granular material conveyance

- Air and gas supply

- Pump discharge

- Spray systems

- Protective jacketing

- Potable water

- Irrigation systems

Read our article on food-grade hoses to learn more.

Polyurethane pressure and suction hose

Figure 3: Suction-pressure spiral hose – Polyether polyurethane coat with embedded copper-coated steel wire coil

Polyurethane (PU), another common material for suction and pressure hoses, has greater elasticity and abrasion resistance when compared to PVC. Its natural flexibility does not require additives to retain elastic properties. Additionally, PU hoses can be used at higher temperatures compared to PVC hoses (-40 °C up to 90 °C). Similar to other pressure and suction hoses, a high tensile-strength material is embedded in the hose to ensure that the hose does not burst under vacuum or pressurized applications. An example of an industrial hose made of polyether-PU with a copper-coated steel wire coil embedded in the hose is shown in Figure 3.

Because of its versatility with temperature and flexibility, PU pressure and suction hoses have a wider range of use. In general, PU has decent chemical resistance. However, differentiation has to be made between PU-ether and PU-ester; PU-ether has a better hydrolytic stability and PU-ester is more resistant to hydrocarbons like oils and solvents. PU hoses are used in the chemical, wood, and paint and lacquer industries. Typical uses are:

- Conveying gasses

- Transport of wood chippings

- Transporting paint fog or dust

- Conveying granulated material such as gravel, sand, dust, wood, or grain

Wear and tear

Abrasion

No pressure and suction hose can completely avoid abrasion damage due to friction from solid material transport. Abrasion is the process of scraping or wearing the inner layer of the hose. This is most noticeably in hoses with a rough inner tube. PU’s low friction coefficient allows only minor friction of transferred materials, such as gravel, sand, or cement. PU hoses oftentimes are more abrasion resistant than standard PVC.

Medium

When considering a pressure and suction hose, evaluating the medium the hose will be transporting is important. Carrying non-optimal materials may cause the hose to deteriorate, for example a hose designed to transport water cannot effectively transport gasoline without deteriorating. This decreases the life-span of the hose and/or can result in contamination of the medium due to leeching of the hose-material.

Environmental factors

Other environmental factors, such as sunlight exposure, extreme temperatures, or dragging may affect pressure and suction hoses. In cold temperatures, hoses generally lose flexibility and may cause cracking. In hot temperatures, hoses may break down. UV-exposure due to sunlight might chemically degrade the hose material in a process known as UV-degradation. Additionally, the local environment in which the hose is used is of importance. Hoses used in chemical plants will degrade faster than hoses used in agriculture.

Standards

When purchasing pressure hoses, it is important to consider if they conform to standards both within the European Union (EU) and the United States (US). In general, the most important standards are for hoses which come in contact with food-grade products or with chemicals. For these types of hoses, the European Union and the United States have developed their own standards. The main standards for each region are briefly discussed below.

European Union

In the EU, for food usage, food contact materials must contain no halogen or plasticizer additives and have reduced flammability. One important standard is Regulation (EC) 1935/2004. It states that food-contact materials (such as plastic) must not release their constituents into food at levels that would endanger human health. EC No. 10/2011 also guides on which plastics can be used in contact with certain food products.

In Germany, tubing must be classified as not flammable due to DIN 4102 B1. The B1 rating indicates it has passed the fire shaft test, where the material is hung in a test cabinet and exposed to a flame for ten minutes. It also must conform to TRGS 727 , a way to evaluate and avoid ignition hazards resulting from electrostatic charging in hazardous areas.

United States

In the US, the FDA regulates materials that are intended to be in contact with food. A common standard is the FDA 21 CFR 177.2600, which is concerned with indirect food additives. Molecules could potentially migrate from the plastic pressure hose into foods and this regulation ensures food safety. FDA 21 CFR 178.2010 states allowed antioxidants and/or stabilizers for polymers to ensure food safety.