What is a Rivet and How Does It Work?

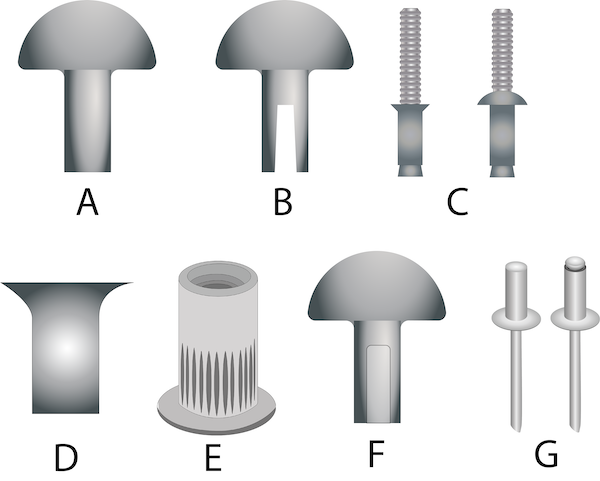

Figure 1: Pop rivets

A rivet is used to join two materials together permanently and is able to withstand vibrations and tensions better than a screw or bolt. There are various rivet types available for use across different industries. This article examines the parts of a rivet, how it works, and the different types of rivets used.

Table of contents

- What is a rivet?

- How do rivets work?

- Different types of rivets

- How do pop rivets work?

- How to calculate rivet size?

- Advantages and disadvantages

- Rivet applications

- FAQs

View our online selection of pneumatic rivet guns!

What is a rivet?

A rivet is a popular mechanical fastener to join two or more materials. A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. The tapered end of the shaft is called the rivet’s tail. The tail looks like a metal pin. Rivets are used to join large structural pieces and small electronic assemblies. The shafts are hollow with another internal piece called a mandrel. The mandrel allows the riveter to deform the tail of the rivet without striking it directly.

How do rivets work?

First, a hole is drilled or punched in the materials to be connected. The rivet is inserted between both holes. The tail is then upset or bucked (deformed) by mechanical force using a hammer or rivet gun. The tail then expands to around 1.5 times the original diameter of the shaft, holding the rivet in place between both materials. The deformation smashes the tail, making it flatter, resulting in a dumbbell-shaped rivet. The original head of the rivet is called the ‘factory head,’ and the deformed end is called the ‘buck-tail.’

A rivet can support tension on each end of the structure. The permanently formed heads at both ends prevent the rivet from detaching from the drilled hole. The rivet shaft prevents any radial movements. Rivets are designed for permanent joints similar to welding or structural adhesives. But, contrary to welded connections, rivets resist vibrations and secure joints better.

Figure 2: Using a rivet gun for riveting aluminum parts together.

Different types of rivets

A large variety of rivets is available due to the many different materials that need joining. Here are some of the different kinds of rivets and how they work.

Solid rivet

A solid rivet (Figure 3 labeled A) consists of a solid shaft with a head at one end. The tail of a solid rivet is deformed using a rivet gun or hammer to keep it in place.

Split rivet

A split rivet (Figure 3 labeled B) has a divided shaft to create more surface area after it has been passed through the joint. The rivet has a sharp end, and the added surface area keeps the rivet from pulling back through softer materials such as leather, wood, and plastic. Split rivets are commonly used in basic repair works at home, and they are not used in critical applications.

Blind rivet (pop rivet)

Blind rivets (Figure 1) are suitable when one side of the joint cannot be seen or accessed. They are also known as ‘pop rivets’ and use a rivet gun to pull a mandrel through the hollow shaft of the rivet after being inserted through the hole joining two surfaces. The mandrel deforms the rivet’s body and allows the riveter to fasten the materials with access to only one side of the surface. The mandrel snaps off at a ‘necked’ point where the mandrel is weakest, leaving it more or less flush with the head of the rivet.

Friction lock rivet

Also known as a self-plugging rivet, friction lock rivets (Figure 3 labeled C) are a type of blind rivet which use the internal pressure of a stem that is drawn through a hollow sleeve which expands the shaft and uses pressure within the shaft to join materials and plug the hole behind it.

Self-piercing rivet

Self-piercing rivets, or SPRs, (Figure 3 labeled D), do not need pre-punched holes, unlike other rivet types. SPRs are cold-forged in a semi-tubular shape, and the end geometry has a groove that aids the rivet in piercing the material to be joined. These types of rivets help create a gas/water-tight joint.

Threaded rivet

Threaded rivets (Figure 3 labeled E) are blind rivets with internally threaded, hollow shafts. These rivets thread onto a mandrel on a rivet gun. The mandrel is pulled through the shaft, which upsets the shaft. These blind rivets are solid and sometimes feature external ridges that allow for better surface area contact within the pilot hole.

Semi-tubular rivet

Much like a solid rivet, a semi-tubular rivet (Figure 3 labeled F) has a hole at the end of the tail. The hole causes the shaft to roll outward when force is applied, hence requiring less force for application and assembly.

Oscar rivet

An oscar rivet (Figure 3 labeled G) is similar to a blind rivet, but the only difference is that the shaft gets split and folds out when the mandrel is drawn throughout the rivet. Oscar rivets are ideal for applications involving high vibrations where the rear surface is inaccessible.

Figure 3: Rivet types: solid rivet (A), split rivet (B), friction lock rivet (C), self-piercing rivet (D), threaded rivet (E), semi-tubular rivet (F), and oscar rivet (G).

How do pop rivets work?

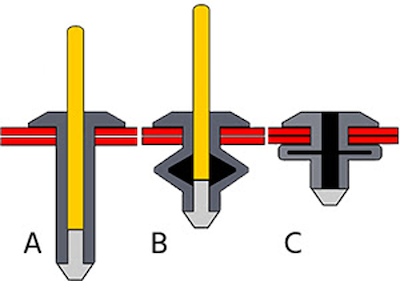

Pop rivets are a type of blind rivet, meaning they are attached from only one side. Perform the following steps to use a pop rivet:

- Drill or punch a pilot hole through both surfaces.

- Put the mandrel of the rivet into the rivet gun’s nose piece and push the shaft through the punched or drilled holes to create the joint.

- The compression of the rivet gun’s trigger pulls the mandrel through the hollow shaft to upset the tail end and create a solid, riveted joint.

- At the appropriate depth, the mandrel snaps off at the "necked" area.

- The user can set the next rivet and repeat the process as necessary.

Figure 4: Pop rivet compression stages; The rivet in its original state (A), rivet gun pulling the mandrel (yellow) through the rivet body (B), and properly sealed surfaces (C)

How to calculate rivet size?

Rivets come in a wide range of sizes; length and width are equally important. As they are fastening materials, an estimate of the number of rivets required is essential in determining proper surface area distribution to ensure the strength and stability of the completed structure. Rivets need to fit through the pilot hole of both surfaces and then expand to work correctly. A user must contend with lateral and vertical forces, which could shear the rivet. General estimates for the rivet dimensions are:

- The length of the rivet should be the sum of the thickness of all riveted materials plus 1.5 times the diameter of the rivet. A rivet that is too small can lead to the rivet pulling through the material, and a rivet shaft that is too thin could easily shear under pressure.

- The rivet diameter should be three times the thickness of the thickest piece of joined material.

For example, when joining together two sheets of metal that have a 2 mm thickness, the diameter of the rivet should be 6 mm. A 6.35 mm (one-quarter inch) rivet is suitable here. The length of the rivet should be at least 9.5 mm.

Advantages and disadvantages of rivets

Advantages

- Inexpensive

- Rivets can join two dissimilar materials (like copper and aluminum plates).

- User/environment-friendly process as no fumes and gasses are produced as in welding.

- Reliable joints, especially when subjected to vibrations.

- The quality inspection of a rivet joint is easy when compared to a welded joint.

Disadvantages

- The riveted joints are bulkier compared to welded joints.

- The rivet projection affects aesthetic appearance.

- High production time for assembly

- Holes required to insert rivets cause stress concentration.

Rivet applications

Rivets are very common and find their way into various applications to bind two or more materials. Many industries use rivets, including:

- Automotive applications

- Household objects

- Electrical appliances

- Kitchen knives

- Aerospace industry

- Satellites and spacecraft

- Shipbuilding and other nautical applications

Read our pneumatic and electric rivet gun articles for more details on the working of each rivet gun type.

FAQs

What is a rivet?

A rivet is a popularly used mechanical fastener to join two or more materials.

Are rivet joints strong?

Rivets can permanently set a solid joint. When done correctly, they allow no movement between the layers of material.

Why are blind rivets useful?

One particular advantage is being able to rivet from only one side, whereas a bolt will require tapping threads or using a nut on the other side to join two surfaces.