Small Pneumatic Cylinders For Confined Spaces

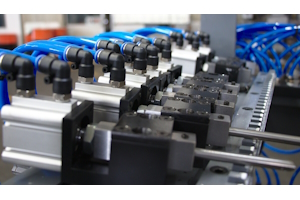

Figure 1: Compact pneumatic cylinders connected to air hoses

Small pneumatic cylinders are essential components in industrial applications where space is limited. These compact devices offer efficient motion control and are designed to fit into confined spaces without compromising performance. They are ideal for automation systems, robotics, and other machinery that require precise and reliable actuation in tight areas.

Table of contents

- Types of small pneumatic cylinders

- Specifications

- Applications

- Force output - standard vs compact pneumatic cylinders

- FAQs

View our online selection of pneumatic cylinders!

Types of small pneumatic cylinders

- Short-stroke pneumatic cylinder: Any of the pneumatic cylinders in this article can be classified as short-stroke cylinders. Typically, a short-stroke pneumatic cylinder can have a minimum stroke length of 2.5 mm and a maximum stroke length of 100 mm. However, the exact stroke length of a pneumatic cylinder classified as short stroke depends on the manufacturer.

- Compact pneumatic cylinder: A compact pneumatic cylinder is typically identified by two key features: length and piston diameter. A compact pneumatic cylinder's body length is as close to its stroke length as possible. Its stroke length is short stroke. Compact pneumatic cylinders have relatively large bore sizes (piston rod diameter) relative to their stroke length. This ratio allows the compact pneumatic cylinders to provide high force in a small package.

- Flat pneumatic cylinders: Flat pneumatic cylinders are narrow on one axis instead of the rectangular prism shape that traditional pneumatic cylinders typically have. Flat pneumatic cylinders can be compact and short stroke, however they can also have long stroke lengths up to 500 mm.

Figure 2: A Festo compact cylinder (left) and a Festo flat cylinder (right).

Specifications

Table 1 provides specifications for Festo compact pneumatic cylinders and flat pneumatic cylinders. Note that the double-acting flat pneumatic cylinders have models with stroke lengths above 100 mm. Pneumatic cylinders with stroke lengths above 100 mm are not considered short-stroke pneumatic cylinders.

Table 1: Small pneumatic cylinder specifications

| Pneumatic cylinder type | Design | Piston diameter (mm) | Stroke length (mm) | Max force in (N) | Max force out (N) |

Compact |

Single acting | 6 - 100 | 5 - 25 | 4 - 377 | 9 - 4516 |

| Double acting | 6 - 125 | 5 - 80 | 9 - 6881 | 17 - 7363 | |

Flat |

Single acting | 3 - 22 | 10 - 50 | - | 3.8 - 205 |

| Double acting | 12 - 63 | 10 - 500 | 51 - 1682 | 68 - 1870 |

Applications

Small pneumatic cylinders, whether compact or flat, are suitable for the same types of applications. These pneumatic cylinders are typically chosen for their short-stroke characteristics, which provide fine control in delicate applications. Some example applications are:

- Assembly lines: In a car manufacturing plant, short-stroke cylinders can be used to align door panels before they are welded to the frame. They provide the precise movement required to ensure the panels are perfectly positioned.

- Packaging equipment: In a bottling facility, short-stroke cylinders can be used in the capping machines to apply caps to bottles precisely. The compact design allows them to fit into tight spaces within the machinery, and their precise movement ensures that each cap is applied correctly.

- Electronics manufacturing: During the production of smartphones, short-stroke cylinders can be used to place microchips onto circuit boards. These cylinders are ideal for tasks requiring delicate handling and precise placement, ensuring the components are not damaged during assembly.

- Medical devices: In laboratory automation, short-stroke cylinders can be used to move small vials or test tubes from one station to another. Their compact size and precise control make them suitable for use in environments where space is limited and accuracy is critical, such as in automated blood testing machines.

- Automotive industry: In the assembly of car seats, short-stroke cylinders can be used to fasten upholstery materials to the seat frames. The ability to provide controlled, short movements in confined spaces ensures that the materials are securely attached without damaging them.

Force output - standard vs compact pneumatic cylinders

Small pneumatic cylinders output significant force despite their size. However, it's important to understand their limitations in order to determine if they are actually suitable for an application. Comparing small pneumatic cylinders to standard pneumatic cylinders (e.g., ISO 15522 pneumatic cylinders) is a good place to start to understand this limitation.

Table 1 gives general information on the force output of small pneumatic cylinders. The next section provides simplified information on the force output of standard pneumatic cylinders. Read our article on calculating pneumatic cylinder force output for a more in-depth understanding of how this is done.

Example calculations for standard pneumatic cylinders

To calculate the force output of a pneumatic cylinder, use the following formula:

Force = Pressure x Area

Where:

- Pressure is the operating pressure in pascals (Pa).

- Area is the cross-sectional area of the cylinder bore in square meters (m²).

Example:

Assuming a maximum operating pressure of 10 bar (1,000,000 Pa) and a bore size of 32 mm:

- Convert the bore size to meters: 32 mm = 0.032 m

- Calculate the area:

- Calculate the force:

Table 2: Bore sizes and force output for ISO 15522 pneumatic cylinders

| Bore Size (mm) | Area (m²) | Force (N) |

| 32 | 0.000804 | 804 |

| 63 | 0.003117 | 3117 |

| 100 | 0.007854 | 7854 |

| 320 | 0.080425 | 80,425 |

FAQs

What is a small pneumatic cylinder?

A small pneumatic cylinder is a compact actuator used for motion control in tight spaces, providing efficient and reliable actuation.

How does a compact pneumatic cylinder work?

A compact pneumatic cylinder uses compressed air to move a piston, creating linear motion in confined spaces.

What are the benefits of a Festo compact pneumatic cylinder?

Festo compact pneumatic cylinders offer precise control, durability, and efficient performance in limited space applications.

What is a short stroke pneumatic cylinder?

A short stroke pneumatic cylinder is designed for applications requiring minimal piston travel, ideal for tight spaces.