Thermocouple - Working Principle, Types, and Applications

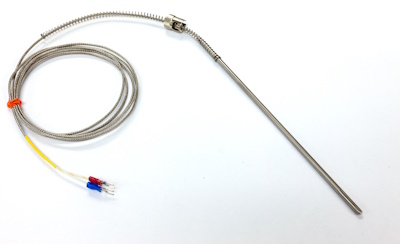

Figure 1: Thermocouple

A thermocouple is a temperature sensor that converts thermal energy into electrical voltage, which can be used to deduce temperature. Accurate temperature measurement in industrial processes ensures equipment's efficient operation and safety. This article explores a thermocouple's features, working, types, and applications.

Table of contents

- Thermocouple working

- Features

- Material and types

- Applications

- Limitations

- Using a thermowell with a thermocouple

- FAQ

View our thermowell and bimetallic thermometer selection here!

Thermocouple working

A thermocouple is a sensor for measuring temperature. It consists of two wires of different metals (Figure 2 labeled B and C) joined at one end. When the junction of the two wires is heated, a voltage is generated between the free ends of the wires. The voltage generated is proportional to the temperature difference between the wires' junction and free ends.

Figure 2: Thermocouple working: hot junction (A), wire Type 1 (B), wire Type 2 (C), cold junction (D), and voltmeter (E).

Measurement process

To measure the temperature with a thermocouple, one end is placed where the temperature will be measured (the hot junction, Figure 2 labeled A), and the other is placed at a known reference temperature (the cold junction, Figure 2 labeled D). The voltage generated by the thermocouple is then measured (Figure 2 labeled E), and the temperature at the hot junction can be calculated using a calibration table. The voltage generated by a thermocouple is very small, typically only a few millivolts, so a thermocouple amplifier is often used to amplify the small voltage signal from the thermocouple to a level that can be easily measured.

Figure 3: Thermocouple calibration and documentation process

Features

Thermocouples can measure a broad range of temperatures, from very cold to extremely hot. They can respond quickly to changes in temperature. This makes them well-suited for applications where rapid temperature measurements are required.

Material and types

Thermocouples are classified into different types based on the materials used in their construction. These materials determine the thermocouple's temperature range, accuracy, and cost.

Table 1: Thermocouple types based on their materials

| Type | Thermoelectric element | Temperature range (𐩑C) | Temperature range (𐩑F) |

| B | Platinum (6% Rhodium)/Platinum (30% Rhodium) | 1370 to 1700 | 2498 to 3092 |

| E | Chromel/Constantan | 0 to 870 | 32 to 1598 |

| J | Iron/Constantan | 0 to 760 | 32 to 1400 |

| K | Chromel/Alumel | 0 to 1260 | 0 to 2300 |

| N | Nicrosil/Nisil | 0 to 1260 | 0 to 2300 |

| R | Platinum (13% Rhodium)/Platinum | 870 to 1450 | 1598 to 2642 |

| S | Platinum (10% Rhodium)/Platinum | 980 to 1450 | 1796 to 2642 |

| T | Copper/Constantan | -200 to 350 | 328 to 662 |

Applications

Thermocouples are used for temperature measurement in various applications due to their wide temperature range, durability, and simplicity.

- Industrial process control: Control the temperature of industrial processes, such as chemical reactions, furnaces, and ovens

- Scientific research: High-temperature measurements are used in physics research, aerospace engineering, material science, and environmental monitoring

- Residential and commercial applications: Everyday appliances and equipment, such as thermostats, water heaters, ovens and stoves, HVAC systems, and industrial boilers

- General temperature measurement: Monitoring the temperature of liquids, gasses, and solids, measuring temperature gradients, recording temperature data over time, and controlling temperature-sensitive processes

For example, in a steel mill, thermocouples monitor the temperature of furnaces that heat steel to high temperatures before it is shaped into various products. Accurate temperature control is crucial in this process to ensure the quality and properties of the steel. Thermocouples are inserted into the furnace walls or the molten steel to measure the temperature. The voltage generated by the thermocouples is then transmitted to a control system that adjusts the fuel supply to the furnace to maintain the desired temperature.

Figure 4: Thermocouple in a heater

Limitations

Thermocouples are susceptible to electrical noise, which can interfere with their operation. This can be mitigated by using shielded cables and grounding the thermocouple properly.

Using a thermowell with a thermocouple

Thermowell

A thermowell is a cylindrical fixture designed to shield temperature measurement devices like a thermocouple when they measure temperature in harsh industrial environments. The thermowell is a protective barrier that separates the thermocouple from the liquid and isolates the liquid from the external environment. This helps protect the temperature sensor from harsh process conditions, prevention of contamination, and easy sensor replacement.

When to use a thermowell

Whether or not a thermowell is needed for a particular application depends on several factors.

- Process conditions: If the process fluid is corrosive, erosive, or under high pressure, a thermowell is needed to protect the thermocouple from damage.

- Temperature range: If the process temperature is high or fluctuating rapidly, a thermowell can help improve the thermocouple's accuracy.

- Maintenance considerations: If the thermocouple needs to be replaced frequently, a thermowell can make this process easier and less disruptive.

- Cost: Thermowells can be more expensive than thermocouples, so weighing the thermowell's cost against its benefits is important.

A thermowell might not be necessary if the environment is benign and the sensor does not require frequent maintenance or replacement. For example, a thermowell is typically not required in a residential water heater because the environment is less harsh, involving only moderate temperatures and non-corrosive potable water, which poses minimal risk to the thermocouple. However, a thermowell is often needed in a chemical processing plant due to corrosive chemicals, high pressures, and temperatures that could damage a thermocouple.

Figure 5: Thermowell

Read our bimetallic thermometer overview article for more details on the working and design of bimetallic thermometers.

FAQ

What is the difference between a thermowell and a thermocouple?

In the 'thermowell vs thermocouple' comparison, a thermocouple is a temperature sensor, while a thermowell is a protective sleeve designed to shield a temperature sensor from fluid flows, high pressure, and corrosive environments.