Repair Threads With a Thread File

Figure 1: Thread files are suitable for damaged threads that do not have severe damage.

A thread file is a specialized tool designed to repair thread damage. Thread failure is a common issue that can occur due to incorrect bolt torque, prolonged vibration, or extended use over time. While smaller components like individual screws or nuts can be easily replaced, larger, expensive, or specialized parts often require repair. This article will guide through the process of using a thread file to repair damaged threads on screws and bolts.

Table of contents

- What is a thread file?

- Types of thread files

- When to use a thread file

- How to use a thread file

- Advantages and disadvantages of using a thread file

- Comparing thread files to other thread repair methods

- FAQs

View our online selection of taps and dies!

What is a thread file?

Constructed from extra-hardened tool steel, a thread file is particularly effective for soft materials like lead, zinc, brass, and even unhardened steel. A thread file (Figure 2) typically has a square shank with rows of teeth that match common thread standards. Each side of the square rod features teeth with different pitches, making the tool versatile for various thread sizes.

Figure 2: A thread file has a square shank and rows of teeth that are compatible with common thread standards.

Types of thread files

There are thread files suitable for metric and imperial threads. It is recommended to buy a thread file set that includes both.

- Metric thread files: These files are suitable for metric threads and cover pitches ranging from 0.8 mm to 3 mm (M5 to M27).

- Imperial thread files: These files are suitable for unified threads and cover pitches such as 24, 20, 18, 16, 14, 12, 11, and 10 threads per inch.

When to use a thread file

Thread filers are ideal for a variety of applications, including cleaning threads by filing off foreign materials and post-processing threads for correction and repair. They are particularly useful in situations where a tap and die set is not suitable, especially for wider threads. Additionally, thread files are effective for addressing light damage, dirt, and burrs that do not require complete re-threading.

How to use a thread file

Using a thread repair file is simple but may take some practice to perfect the method seen below.

- Step 1:Determine the correct pitch: Use a thread pitch gauge. The gauge's teeth should fit perfectly into the threads without gaps. Alternatively, use the thread file to determine the pitch by gently pressing its side against the thread to see if the teeth fit.

Figure 3: Use a pitch gauge, or the thread file itself, to determine the thread's correct pitch.

- Step 2: Prepare the workpiece: Mount the damaged screw or bolt in a vise or chuck to keep it secure during the filing process. This ensures stability and precision while working.

Figure 4: Secure the threaded piece (bolt or nut) so it will not move during the filing process.

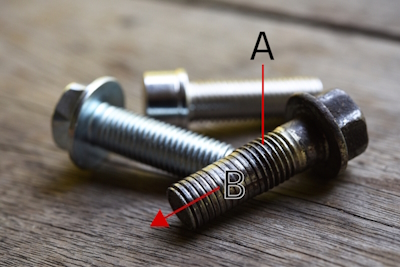

- Step 3: Start filing: With the correct pitch facing the screw or bolt, begin filing at the same angle as the threads. Apply medium pressure and start filing just next to the damaged section, then work across the entire area. For internal threads, press the end of the thread file tool against the thread and move it around, following the thread inside the hole.

Figure 5: Start filing next to the damaged part of the thread (A), and move towards the damaged section and across it (B).

- Step 4: Check progress: Periodically run a nut over the repaired section to check if it runs smoothly. Continue filing until the nut moves freely over the previously damaged threads.

Figure 6: Periodically test the repair job by attaching a nut to the bolt or vice-versa if repairing internal threads.

- Step 5: Final adjustments: Make any final adjustments to ensure the thread is fully restored. This may involve additional light filing to smooth out any remaining rough spots.

Advantages and disadvantages

Advantages

- Versatility: A single thread restoring file can work on multiple thread sizes, making it a handy tool for various applications.

- Economical: Compared to other thread restoration tools, thread files are cost-effective and offer a low barrier to entry.

- Compact: Easy to store and readily accessible when needed.

Disadvantages

- Labor-intensive: Using a thread file requires effort and time, especially for internal threads.

- Skill requirement: Inexperienced users may find it challenging to achieve satisfactory results and risk causing additional damage.

Comparing with other thread repair methods

For extensive damage or when precision is critical, using thread taps or cutting dies might be more suitable.

- Thread files vs thread taps: Thread files are better suited for cleaning and minor repairs, while thread taps are used for cutting new threads or restoring severely damaged internal threads.

- Thread files vs thread cutting dies:Thread cutting dies are used for creating or restoring external threads, but they require more setup and are less versatile than thread files.

FAQs

Can a thread file be used on hardened steel?

Thread files are most effective on softer materials like lead, zinc, brass, and unhardened steel. They may not be suitable for hardened steel.

How do I know if I am using the correct pitch on the thread file?

Use a thread pitch gauge to match the pitch of the damaged thread. Alternatively, test the fit of the thread file's teeth against the thread.

What should I do if the thread file isn't working?

Ensure you are using the correct pitch and applying the right amount of pressure. If the damage is too severe, consider using a tap or die set.

Can I use a thread file on both internal and external threads?

Yes, thread files can be used on both internal and external threads, but the technique will differ slightly.