Different Types of Pliers And How They Work

Figure 1: There are various pliers designed for specific tasks.

Pliers are used for a variety of tasks, from holding and bending objects to cutting or twisting wires. Having different types of pliers in a toolbox can be very useful. This article overviews the various plier types, their specific uses, and how they contribute to the efficiency of different tasks. Understanding the unique strengths and applications of each plier type can significantly enhance one's skills and effectiveness in both professional and DIY projects.

View our online selection of pliers!

Table of contents

Design of pliers

Pliers generally consist of a few key parts:

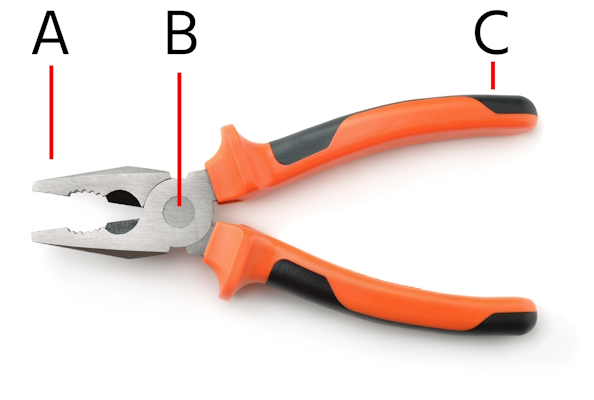

- The head or jaws (Figure 2 labeled A)

- The pivot (Figure 2 labeled B)

- The handles (Figure 2 labeled C)

The handle is where the user grips the tool and applies force. The pivot allows the jaws to open and close, and the jaws are the working end of the pliers. Depending on the type of pliers, the jaws can have various features designed for specific tasks such as cutting, gripping, or bending. Some pliers also have a fulcrum or a joint, which can be adjusted to increase the tool's leverage. These components work together to make pliers a versatile and invaluable tool in many fields.

Figure 2: Pliers typically have a head or jaws (A), a pivot (B), and handles (C).

Types of pliers

There are many types of pliers. Some pliers are for very specific tasks, whereas others are more versatile and have functions that overlap with other plier types. The following list is not a complete list of pliers but a list of some of the most commonly used pliers. Each type has a good reason to be found in a toolbox.

Combination pliers

Combination pliers (Figure 2), also known as lineman's pliers, are used mainly by electricians to bend, grip, twist, and cut wires and cables. Made of hardened steel with insulated handles, these pliers have rounded jaws for bending wire and a cutting edge for snipping it. Their squared-off, serrated nose provides a secure grip. They're used mostly in electrical work, like installing and repairing wiring systems, and in telecommunications and network engineering.

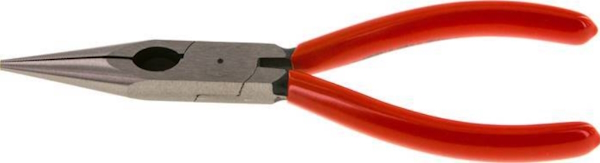

Needle nose pliers

Needle nose pliers, also known as long nose pliers, are primarily used for precise tasks that require a high level of detail, including bending, re-positioning, and snipping wires. The long, thin jaws are perfect for reaching into tight spaces where other pliers might not fit. They are often used in electrical work, jewelry making, and crafting due to their precision and versatility. The pliers are typically made of sturdy steel and have insulated handles for safety. In addition, they usually have a cutting edge near the base of the jaws for cutting and trimming wire.

Figure 3: Needle nose pliers

Angled needle nose pliers

Angled needle nose pliers have elongated, slender jaws angled at the end, typically around 45 to 90°. The angled tip allows users to work around obstructive objects and perform tasks at odd angles.

Figure 4: Angled needle nose pliers

Cutting pliers

Cutting pliers, also known as diagonal pliers or wire cutters, are commonly used for cutting wire, nails, and other materials. They have a sharp edge and a pivot near the cutting edge, providing the leverage needed for cutting through tough materials. Cutting pliers are used in electrical work, jewelry making, and various types of assembly or repair work. The tool is typically made of high-quality steel to withstand the stress of cutting, and the handles are usually insulated for safety. The sharp, angled head allows the user to cut close to flat surfaces and in tight spaces.

Figure 5: Diagonal cutting pliers

Nail pincers

Nail pincers, also known as nail pullers or carpenter's pincers, are primarily used for extracting nails from wood or other materials. Their jaws have a sharp, claw-like design that firmly grips on nails. The handles provide leverage, enabling the user to pull out nails with minimal effort. In horseshoeing, nail pincers are used to remove old nails from the horse's hoof, allowing for the safe and efficient replacement of the shoe. Nail pincers are most commonly used in carpentry, construction, and upholstery work to dismantle structures or reuse materials.

Figure 6: Nail pincers

Grip pliers

Grip pliers, also known as locking pliers, firmly grip and hold various types of materials. They have adjustable jaws that can be locked into position, allowing the user to clamp onto objects of different sizes without the need to apply continuous hand pressure. This makes them useful for tasks that require a strong, steady hold, such as welding, bending, or compressing materials. Grip pliers are commonly used in metalworking, automotive repair, and plumbing. They can also be used as a temporary clamp to hold pieces together during gluing or fastening.

Figure 7: Grip pliers

Wire stripping pliers

Wire stripping pliers are specialized tools for stripping the insulation from electric wires. They have a series of holes or notches of varying sizes that correspond to different wire gauges. The user inserts the wire into the appropriate hole and pulls, which removes the insulation without damaging the wire underneath. These pliers are most commonly used in electrical work, particularly in tasks involving the installation, repair, or modification of wiring systems. In addition to stripping, many wire stripping pliers also have cutting and crimping capabilities, making them versatile tools for electricians, technicians, and DIY enthusiasts.

Figure 8: Wire stripping pliers

Water pump pliers

Water pump pliers, also known as pipe wrenches, are primarily for gripping and turning nuts, bolts, pipes, and other cylindrical objects. They have long, adjustable jaws that can be set to several positions, allowing them to grip a wide range of sizes. The serrated jaws provide a firm, non-slip grip, making water pump pliers ideal for tasks that involve plumbing, automotive work, and general home repair. They're particularly useful in situations where a strong, secure grasp is needed, such as tightening or loosening rusted fittings.

Figure 9: Water pump pliers

Electrical installation pliers

Electrical installation pliers are a multi-functional tool designed specifically for electrical work. They combine several functions, including cutting, stripping, bending, and gripping, making them useful in various electrical tasks. The cutting edge is used for cutting wires and cables, while the stripping notches are strip insulation from wires of different gauges. The round jaw is for bending wire, and the serrated gripping surface allows for a firm hold on various materials. Electrical installation pliers are commonly used in tasks involving the installation, maintenance, and repair of electrical and telecommunications wiring.

Figure 10: Electrical installation pliers

Snap ring pliers

Snap ring pliers are used for installing and removing snap rings, also known as circlips or C-clips, which are used to hold components onto a shaft or in a housing/bore when installed in a groove. These pliers are most suitable for applications in automotive works, machinery operation, or electronic repair, where retaining rings are commonly found. Snap ring pliers come with specially designed jaws and tips to easily manipulate these small components. These pliers are typically used in pairs and can be either internal or external, signifying whether they are designed to work with rings in a housing or on a shaft, respectively.

Figure 11: Snap ring pliers

FAQs

What pliers are most common?

The most commonly found pliers in a toolbox are combination pliers, needle nose pliers, and diagonal cutting pliers. Wire stripping pliers are also relatively common.

How many types of pliers and their uses?

There are many types of pliers; some people suggest over 40 types. Their uses range from gripping, bending, twisting, pulling, and cutting various materials.