Type of Valve Handles: Lever and Handwheel

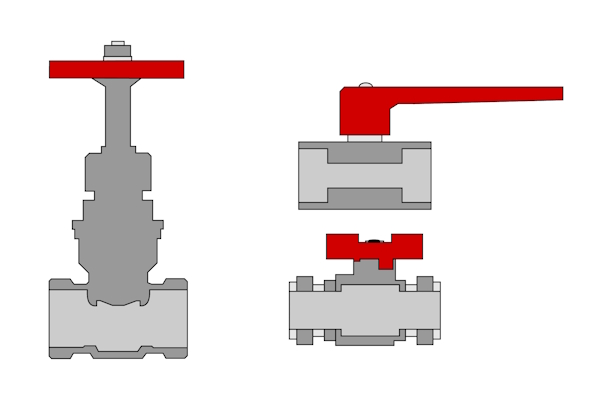

Figure 1: Lever handles are used with ball and butterfly valves (two left valves), and handwheels are used with gate and needle valves (two right valves).

Understanding the differences between lever and handwheel handles can help select between different types of valves for specific applications. The two most common types are lever handles and handwheels.

Lever handles are typically used for quick and easy operation. They are often found on ball valves and other shut-off valves. They allow for rapid opening and closing with a simple 90-degree turn.

Handwheels provide precise control. They are often used with globe valves for detailed adjustments. Handwheels are also used with gate valves for tight closing and to reduce pressure loss.

Figure 2: Relative space requirements for different types of valves with handles. A handwheel valve (left), extended handle lever valve (top right), and butterfly handle ball valve (bottom right).

Table of contents

View our online selection of valves!

Lever handles

Lever types are widely used in industrial applications due to their simplicity and efficiency. They have a straight handle attached directly to the valve stem, allowing quick operation with a 90-degree turn.

Lever handles are often used in ball and butterfly valves. They are good for systems that need frequent use or quick shut-off in emergencies. A butterfly valve's handle has the extra functionality of ratcheting between the fully open and fully closed positions. This allows the valve's disc to remain partially opened to regulate flow rates.

They are also popular in residential and commercial plumbing systems for their ease of use and reliability.

Advantages of lever handle valves

- Ease of use: Intuitive operation with minimal effort

- Quick operation: Rapid opening and closing with a 90-degree turn

- Visual indicator: Clear indication of valve status

Limitations of lever handle valves

- Limited control: Not suitable for precise flow adjustments

- Space requirements: Need clearance for a complete 90-degree turn

- Potential for accidental operation: Can be turned easily in high-traffic areas

Ball valves with butterfly handles

A butterfly handle on a ball valve (Figure 3) is the most compact option available, making it ideal for tight spaces. However, because of the handle's small size, it offers the least leverage, which can make opening and closing the valve more difficult, especially in high-pressure situations. Despite this, it is often chosen for installations where saving space is important and the valve does not need to be operated frequently.

Figure 3: A brass ball valve with a butterfly handle

Ball valves with extended handles

Extended lever ball handles offer additional leverage and reach. Lever handles help operate valves that need more force. They provide extra torque to handle high pressure.

Commonly used in industrial settings, long handles are ideal for large ball and butterfly valves. Lever handles are useful for keeping operators safe. They allow operators to stay at a distance when working with valves that handle high temperatures or hazardous materials. Figure 4 demonstrates a ball valve with an extended handle.

Figure 4: A ball valve with a long handle

Handwheel valve handles

Common handwheel valves are:

- Gate valves

- Globe valves

- Needle valves

- Angle seat valves

Handwheel valve handles require multiple turns to open or close a valve fully. These wheel handles provide several functions: tight sealing, flow control via precise adjustments, and operation in small spaces.

However, all of these advantages are not present in all valve types that use handwheels. Gate valves use handwheel handles. However, they are not good for precise flow control beyond being fully open or fully closed. Figure 5 shows a handwheel handle in the form of a valve knob.

Furthermore, handwheel handles can be non-rising, so they operate without moving up or down. This is especially advantageous in small spaces.

Figure 5: A globe valve with a handwheel handle

Advantages of handwheel valves

- Fine control: Handwheels on globe valves and needle valves allow for incremental adjustments, ensuring precise flow regulation

- Tight shutoff: A handwheel can be tightly shut by turning the handle firmly to ensure a secure seal. However, care should be taken not to overturn it to avoid damaging the valve.

Limitations of handwheel valves

- Slower operation: Multiple turns are needed, making them slower than lever handles.

- Space requirements: Although they can have non-rising stems, valves with handwheels are typically taller than valves with levers, making them take up more vertical space.

- Manual effort: More effort may be needed to spin the handwheel than turning a lever handle.

FAQs

What are valve handles?

Valve handles are devices used to manually operate valves, typically available as lever handles or handwheels for different control needs.

What is a lever handle?

A lever handle is a type of valve handle that allows quick operation, often used on ball valves for rapid opening and closing with a 90-degree turn.

What is a handwheel valve?

A handwheel valve uses a wheel-shaped handle for precise control, commonly found on globe and gate valves for detailed adjustments and tight closing.

What is a ball valve extended handle?

A ball valve extended handle is a longer lever handle that provides easier access and operation, especially in hard-to-reach or confined spaces.