Pneumatic Vane Motors

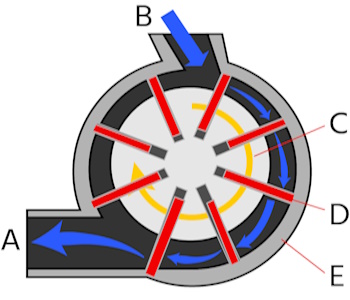

Figure 1: Air vane motor

A pneumatic vane motor is an air-powered device that converts compressed air energy into rotary mechanical motion. These motors are commonly used in various industrial applications, particularly when precise control and variable speed are required. They are also referred to as air vane motors. This article discusses the design, working principle, and various types of pneumatic vane motors.

Table of contents

- Vane motor design and working principle

- Vane motor types

- Advantages

- Disadvantage

- Vane motor applications

- FAQs

View our online selection of pneumatic vane motors!

Vane motor design and working principle

Design

Figure 2 shows the basic construction of a pneumatic vane motor.

- Casing: The casing functions as the external housing of the vane motor, encompassing all other components. The case has two ports:

- Outlet port (A): The compressed air exits the motor through the outlet port.

- Inlet port (B): The compressed air enters the motor through the inlet port.

- Rotor (C): The vane motor's rotor is equipped with evenly spaced slots around its circumference. The rotor rotates eccentrically inside a cylinder, creating crescent-shaped chambers filled and emptied with compressed air to produce torque.

- Vanes (D): The vanes are within the rotor's slots. They move freely within the rotor slots and have a rectangular shape. They are connected to the rotor using a spring.

- Stator (E): A stator is a stationary outer cylinder that contains the rotating rotor and vanes.

Figure 2: Pneumatic vane motor construction: Outlet port (A), inlet port (B), rotor (C), vane (D), and stator (E).

Working principle

A pneumatic vane motor consists of a rotor with vanes that slide in and out of slots. Compressed air enters the chamber, which forces the vanes against the cylinder wall. This creates a pressure differential between the two sides of the vane, which causes the rotor to turn. As the rotor turns, the vanes slide in and out of the slots, creating new chambers and sealing off old ones. The process continues until the compressed air is exhausted.

Here is a step-by-step explanation of the working principle of an air vane motor:

- Compressed air enters the motor through an inlet port.

- The compressed air flows into the chamber and forces the spring-loaded vanes against the cylinder wall.

- The pressure differential between the two sides of the vane causes the rotor to turn.

- As the rotor turns, the vanes slide along the inner wall of the chamber, maintaining the seal.

- When the vanes reach the output port, they are forced back in by the spring force.

- The compressed air is then exhausted from the motor, and the cycle repeats.

The spring force is stronger than the centrifugal force at low speeds, meaning the vanes will be forced against the cylinder wall even before the rotor turns. As the speed of the motor increases, centrifugal force becomes more important. Eventually, centrifugal force will overcome the spring force, and the vanes will slide along the inner wall of the chamber. The spring force is still important at high speeds, however. It helps keep the vanes in contact with the cylinder wall and prevents them from flying out of the motor.

The pressure and flow of the compressed air control the speed of an air vane motor. The higher the pressure and flow, the faster the motor will turn. Vane motors are generally more efficient at higher speeds and lower torques. The vane motor's efficiency decreases as the speed decreases and the torque increases. This is due to increased internal friction and air leakage.

Vane motor types

The vane motor type for a particular application will depend on the application's specific requirements, such as the required speed, torque, noise level, and budget. They are mainly classified based on the following parameters:

- Motor displacement

- Unidirectional or bidirectional motor rotation

Motor displacement

Pneumatic vane motors are classified as unbalanced, balanced, and variable displacement vane motors depending on the motor displacement.

Unbalanced vane motor

The air vane motor discussed in the previous section is unbalanced. They have the rotor eccentrically mounted in the casing. This creates a pressure difference between the two sides of the vane, which causes the rotor to turn. Unbalanced vane motors are simple and inexpensive but can be noisy, less efficient, and have shorter lifespans. Unbalanced vane motors, such as lawn mowers and leaf blowers, are typically used in applications where low cost and high performance are not critical.

Balanced vane motor

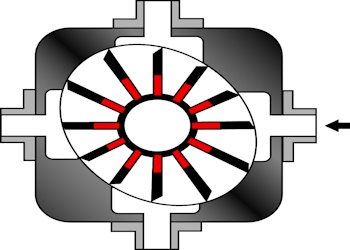

Balanced vane motors have the rotor mounted concentrically in the casing. This eliminates the pressure difference between the vane's two sides, reducing noise and vibration and increasing efficiency and lifespan.

Balanced vane motors are typically used in applications where low noise and vibration, high efficiency, and long lifespan are important, such as in industrial automation equipment and aerospace applications.

Figure 3: Balanced vane motor construction

Variable displacement vane motor

Variable displacement vane motors allow for the adjustment of their output speed and torque by varying the size of the working chambers within the motor. This is typically achieved by changing the position of the vanes. They are more complex and expensive to manufacture than unbalanced or balanced vane motors, but they offer several advantages:

- Controls the motor's speed and torque without changing the compressed air's pressure or flow.

- Operates at a constant speed or torque even if the load/speed on the motor changes.

Variable displacement vane motors are typically used in applications requiring precise speed and torque control, such as industrial automation equipment and robotics.

Motor direction

Air vane motors can be reversible or non-reversible. Reversible motors can rotate in either direction, while non-reversible motors can only rotate in one direction.

- Non-reversible vane motors have a fixed air inlet and outlet port configuration, meaning the motor can only rotate in one direction.

- Reversible vane motors employ a valve mechanism that can switch the roles of the inlet and outlet ports. When the valve is switched, the pressurized air enters through the opposite port, causing the vanes to move in the opposite direction, thus reversing the motor's rotation. In addition to the valve mechanism, reversible vane motors may have different vane designs or the internal geometry of the motor housing to accommodate bidirectional airflow and ensure efficient operation in both rotational directions.

Advantages

Pneumatic vane motors are valued for their simplicity, reliability, and ability to operate in hazardous environments

- Explosion-proof performance: A pneumatic vane motor is designed to operate safely in potentially explosive environments, as its working medium (compressed air) and structural design eliminates the risk of spark generation.

- Versatile: The device can be used in dusty and extremely humid environments.

- Extended operation: The motor can run at full capacity for extended periods without experiencing significant temperature increases and includes overload protection.

- High starting torque: It has a high starting torque, enabling it to start under load. This is because the vanes are spring-loaded and held against the cylinder wall by centrifugal force. The spring pressure on the vanes provides a high initial torque, which allows the motor to start under load.

- Compact and lightweight: Compared to conventional motors, a vane motor has a small unit power size and is lightweight, making it suitable for installation in tight spaces and use with hand tools.

Disadvantages

- The air motors consume relatively expensive compressed air, so the cost of operating them might be greater than that of operating electric motors.

- A vane pump may not be suitable for highly viscous fluids. However, it effectively manages fluids with moderate viscosity and excels at handling low-viscosity substances like L.P. gas, ammonia, solvents, and alcohol.

- Since vanes are freely sliding in slots, air leakage is possible.

Vane motor applications

- Automotive: Used for tasks like tightening bolts or screws, ensuring the correct force is applied.

- Construction: Powers handheld tools like drills and jackhammers, providing portability and power.

- Food and beverage: Used in mixing and blending equipment, allowing speed control for different requirements.

- Industrial cleaning: Powers heavy-duty cleaning equipment like industrial vacuum cleaners.

FAQs

What are the different types of multi vane air motors?

Multi vane air motors can be balanced, unbalanced, or variable depending on how the rotor mounts with respect to the casing.

What are the different factors that affect vane motor efficiency?

The efficiency of a vane motor can be affected by factors such as mechanical friction, fluid viscosity, pressure drop in the system, and the design and manufacturing quality of the motor components.

Can a rotary vane pump be used as a motor?

Yes, a rotary vane pump can be used as a motor by reversing the direction of fluid flow, causing the rotor to rotate, and generating mechanical power.