Vented Ball Valve Overview

Figure 1: A vented ball valve

An externally vented ball valve safely releases upstream pressure and prevents potential damage or hazards, ensuring efficient and reliable operation across various industrial applications. This article provides an in-depth look at vented ball valves, covering their design, functionality, applications, and selection criteria. By understanding these aspects, readers can make informed decisions when purchasing vented ball valves to meet their needs.

Note: There are externally and internally vented ball valves. Internally vented ball valves only release pressure from within the valve itself (between inlet and outlet seals). Externally vented ball valves connect the output to the vent when the valve is closed, which allows it to depressurize the system downstream. This article focuses on externally vented ball valves.

Table of contents

- Vented ball valve design and structure

- How does a vented ball valve work?

- Key applications

- Advantages and disadvantages

- Selecting between mini and standard vented ball valves

- FAQs

View our online selection of vented ball valves!

Vented ball valve design and structure

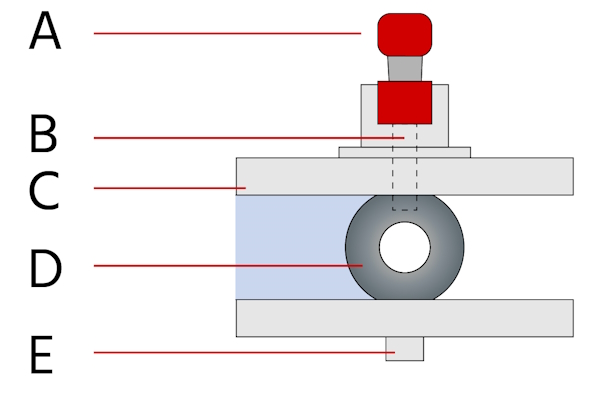

Externally vented ball valves consist of several key components: the handle (Figure 2 labeled A), stem (Figure 2 labeled B), body (Figure 2 labeled C), ball (Figure 2 labeled D), and vent feature (Figure 2 labeled E). The vent differentiates these valves from standard ball valves. It connects the outlet to a vent when the valve is closed, allowing pressure to safely escape from the system.

Figure 2: A vented ball valve diagram with components handle (A), stem (B), body (C), ball (D), and vent feature (E).

Materials

Materials used in vented ball valves vary based on application requirements. Common materials include stainless steel and brass, each offering different levels of corrosion resistance and temperature tolerance.

-

Stainless steel

- Corrosion resistance: Excellent resistance to corrosion, making it ideal for harsh environments and corrosive fluids.

- Temperature tolerance: Can withstand high temperatures, typically up to 200 °C (752 °F).

- Durability: Highly durable and suitable for high-pressure applications.

- Applications: Used in chemical processing, oil and gas, and food and beverage industries.

-

Brass

- Corrosion resistance: Good resistance to corrosion, particularly in water and mild chemicals.

- Temperature tolerance: Suitable for moderate temperature ranges, generally up to 100 °C (392 °F).

- Cost-effectiveness: More affordable than stainless steel, offering a good balance between performance and cost.

- Applications: Commonly used in plumbing, HVAC systems, and water treatment.

How does a vented ball valve work?

The working principle of an externally vented ball valve involves rotating a ball with a bore through it. When the valve is open, the bore aligns with the flow path, allowing fluid to pass through. When closed, the ball rotates to block the flow path, and the outlet is connected to a vent, releasing any upstream pressure.

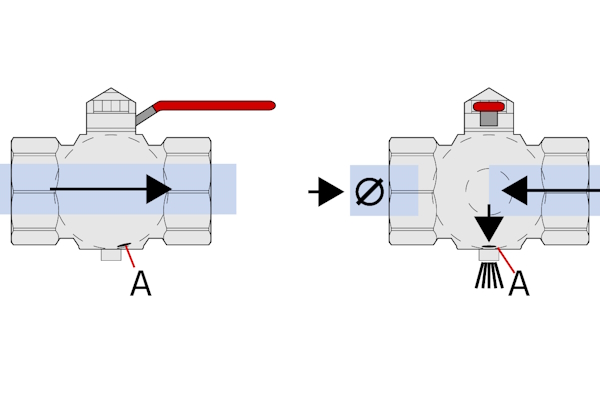

A vented ball valve's design prevents pressure build-up, enhancing safety and reliability. As seen in Figure 3, the bottom of the ball component has a hole that moves when the ball rotates. When open (Figure 3 left), the hole (Figure 3 labeled A) is not aligned with the vent. When closed (Figure 3 right), the hole is aligned with the vent.

Figure 3: The hole in the bottom of the ball component (A) does not align with the vent when the valve is open (left). It aligns with the vent when the valve is closed (right), allowing upstream media to depressurize.

Managing vented media

Selecting the appropriate venting method ensures safety and effectiveness. Consider the fluid properties, potential risks, and regulations before deciding whether to release the fluid to the atmosphere.

Venting to the atmosphere

A ball valve with an air vent can vent directly to the atmosphere. This is acceptable in applications involving non-hazardous fluids such as air or inert gasses. This approach is simple and cost-effective, as it does not require additional components like hoses or tubing.

However, it is crucial to ensure that venting to the atmosphere does not pose any safety or environmental risks. For example, do not vent inert gasses in an enclosed space.

Directed venting

For applications involving hazardous, corrosive, or environmentally sensitive fluids, it is necessary to direct the vented media to a safe location. This is typically achieved using hoses or tubing connected to the vent port of the valve. The vented media can be directed to a containment system to ensure safe handling and disposal. This approach helps prevent exposure to harmful substances and complies with environmental regulations.

Key applications

Externally vented ball valves are used in industries such as chemical processing, oil and gas, and water treatment. They are ideal for applications where pressure build-up could pose a risk, such as in systems handling volatile or hazardous fluids. Externally vented ball valves are also preferable in situations where maintenance or disassembly is required, as they ensure safe pressure release before servicing.

Vacuum applications

Externally vented ball valves are especially suitable for vacuum systems for the following reasons:

- Pressure equalization: Externally vented ball valves help equalize pressure when transitioning between vacuum and atmospheric conditions. This is essential during maintenance or when introducing new materials into the system.

- Preventing vacuum lock: Externally vented ball valves prevent vacuum lock, which can occur when a vacuum is inadvertently maintained in a closed system. By venting the system, these valves ensure that components can be safely opened or disassembled without the risk of damage or injury.

- Controlled venting: They allow for controlled venting of vacuum chambers, which is crucial for processes that require precise pressure management. This is particularly important in applications like semiconductor manufacturing or scientific research, where maintaining specific vacuum levels is critical.

Advantages and disadvantages

Ball valves with a vent have several benefits. They improve safety by stopping pressure from building up, work well in high-pressure situations, and are easy to maintain. But, they might need regular checks to make sure the vent is clear and might release fluid, which could need more safety steps in some places.

Selecting between mini and standard vented ball valves

When choosing between a mini vented ball valve and a standard vented ball valve, consider the specific requirements of the application. Each type offers distinct advantages and is suited to different scenarios.

Mini vented ball valve

- Compact design: Ideal for piping systems with limited installation space. The compact size allows for easy integration into tight spaces.

- Venting borehole: Features a 2.5 mm venting borehole.

- Port size: Equipped with G 1/4, G 1/8, or G 3/8 threaded ports, compatible with a wide range of similarly-sized fittings.

- Material and construction: Made of chromium-plated brass with PTFE (Teflon) sealings.

- Pressure and temperature range: Operates up to 20 bar (290 psi) and suitable for vacuum applications with a minimum pressure of -0.99 bar (-14 psi). Temperature range from -20 to 80 °C (-4 to 176 °F).

- Applications: Best suited for manual operation in compressed air systems where space is a constraint and moderate depressurization is sufficient.

Figure 4: A brass mini vented ball valve

Standard vented ball valve

- Larger bore size: Features bore sizes from 8 mm up to 32 mm, allowing for higher flow rates and more substantial depressurization.

- Venting borehole: Equipped with an M5 venting borehole, suitable for applications requiring more significant pressure release.

- Port size: Comes with G 1/4 to G 1 1/2 threaded ports, compatible with a wide range of similarly-sized fittings.

- Material and construction: Constructed from nickel-plated brass or stainless steel with PTFE sealings.

- Pressure and temperature range: Operates up to 14 or 16 bar (203 or 232 psi) and suitable for vacuum applications with a minimum pressure of -0.98 bar (-14 psi). Temperature range from -10 to 100 °C (14 to 212 °F) or -20 to 200 °C (-4 to 392 °F).

- Applications: Suitable for manual operation in systems requiring higher flow rates and more robust depressurization capabilities.

Figure 5: A brass standard vented ball valve

FAQs

What is a vented ball valve?

A vented ball valve is a type of valve that includes a venting mechanism to release trapped pressure, preventing damage or hazards.

How does a vented ball valve work?

An externally vented ball valve works by using a venting mechanism to connect the outlet to a vent when the valve is closed, releasing pressure from the system.