Pneumatic Whisker Valves - How They Work

Figure 1: A Festo whisker valve

A whisker valve uses a thin, flexible lever, known as a whisker arm, to detect the presence of an object and control air flow. These valves are commonly used in automation systems to detect part movement, act as safety switches, and control air flow in various industrial applications. This article covers the design and operation of whisker valves, their default states, advantages and disadvantages, and specific applications. Additionally, it provides detailed technical data on Festo's FVS-3-⅛ and FVSO-3-⅛ whisker valves.

Table of contents

- Design

- Operation

- Default states

- Whisker valve advantages & disadvantages

- Applications

- Festo whisker valves

Design

- Whisker arm: A thin, flexible lever that extends from the valve body and acts as the sensing element.

- Valve body: Contains the internal components of the valve, including the ports for air flow.

- Ports: Inlet and outlet ports for the pneumatic air supply.

- Flow control mechanism: Typically includes a spool, plunger, or diaphragm that controls the flow of air based on the position of the whisker arm.

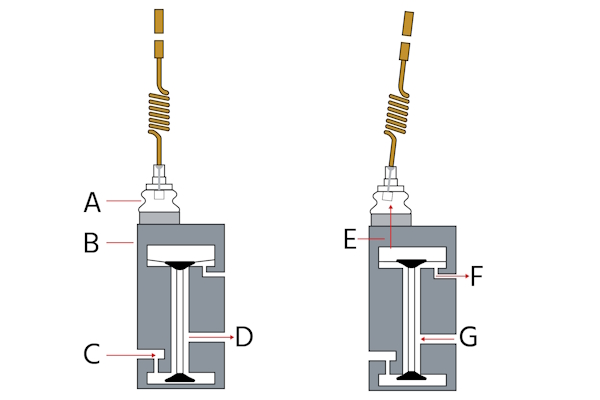

Figure 2: A whisker valve (A) connected to a pneumatic relay (B). In the off position (left), the whisker is not deflected and air flows from the air supply (C) and out the outlet (D). When the whisker is deflected (right), air exhausts from the whisker (E), the exhaust port (F), and from the downstream pneumatic instrument (G).

Operation

Figure 2 illustrates how a whisker valve (Figure 2 labeled A) works with a pneumatic relay (Figure 2 labeled B)to control air flow. In the off position (Figure 2 left), the whisker is not deflected and air flows from the inlet (C) to the outlet (D) and to the downstream pneumatic instrument. When the whisker is deflected, air in the valve is released through the whisker valve port (Figure 2 labeled E), allowing the diaphragm to rise and block air from the inlet. The air exhausts through the exhaust port (Figure 2 labeled F), and any air from the pneumatic instrument returns through the relay (Figure 2 labeled G) and out the exhaust port.

Default states

Whisker valves are 3/2-way valves, meaning they have 3 ports and 2 states, or positions, which are open and closed. Whisker valves can be normally open or normally closed:

- Normally open: Air flows through the whisker valve when the arm is not actuated. When the arm is deflected by an object, the internal mechanism shifts to block the air flow or redirect it to another port.

- Normally closed: Air flow is blocked when the whisker arm is not actuated. When the arm is deflected, the internal mechanism shifts to allow air to flow through the valve.

3-way valve

A 3-way valve in its default state is connected to the air supply and another port is connected to the output. The third port is connected to the exhaust but is blocked. In the actuated state, the air coming from the supply is blocked and air in the valve and the downstream instrument flows out of the exhaust.

If a whisker valve does not have an exhaust port, the valve will simply open or close the air flow path without releasing air to the atmosphere.

Whisker valve advantages & disadvantages

Advantages

- Simplicity: Simple mechanical design with no need for electrical power.

- Reliability: Durable and reliable in harsh industrial environments.

- Cost-effective: Generally less expensive than electronic sensors.

Disadvantages

- Mechanical wear: The whisker arm can wear out over time due to repeated mechanical contact.

- Sensitivity: May not be as sensitive or precise as electronic sensors.

Applications

In machine automation systems, pneumatic whisker-actuated valves detect the movement of parts. When a part touches the whisker, the valve opens or closes. These valves require very low actuating forces and are ideal for systems with varying parts or imprecise positioning. The whisker can be approached from any perpendicular direction. Applications of whisker-operated pneumatic valves include:

- Automation systems: Used to detect the position of parts on assembly lines.

- Safety mechanisms: Can act as a safety switch to stop machinery if an object is detected in a hazardous area. Exhausting air can be a way to quickly depressurize a system to prevent accidents.

- Control systems: In control systems, the exhaust function is often used to reset or vent pressure in a specific part of the system.

- Position sensing: Used in various industrial applications to sense the position of moving parts.

Festo whisker valves

Festo offers two types of whisker valves: the FVS-3-⅛ and the FVSO-3-⅛. Both are 3/2-way valves, but they differ in their default states. The FVS-3-⅛ is a normally closed, monostable valve, while the FVSO-3-⅛ is a normally open, monostable valve. Choose a normally open valve for the default state to allow fluid flow when the valve is not actuated, and a normally closed valve for the default state to block fluid flow when the valve is not actuated.

General technical data

-

Standard nominal flow rate

- FVS-3-⅛: 146 l/min

- FVSO-3-⅛: 175 l/min

-

Valve function

- FVS-3-⅛: 3/2-way valve, normally closed, monostable

- FVSO-3-⅛: 3/2-way valve, normally open, monostable

- Exhaust air flow control: present

- Design: Disk seat valve, piloted

- Direction of flow: Non-reversible

- Pneumatic connection: Gx

- Nominal size: 3.5 mm

- Weight: 130 g

Materials

- Seal: NBR

- Housing: Anodised aluminum

- Note on materials:RoHS-compliant

Operating and environmental conditions

- Operating medium: Compressed air to ISO 8573-1:2010

- Note on operating/pilot medium:Lubricated operation possible (required during subsequent operation)

- Operating pressure range: 3.5 to 8 bar

- Temperature of medium: -10 to 60 °C

- Ambient temperature: -10 to 60 °C

- Corrosion Resistance Class (CRC): 2

FAQs

What is a whisker valve?

A whisker valve uses a thin, flexible lever, known as a whisker arm, to detect the presence of an object and control air flow in automation systems.

How does a whisker valve work?

A whisker valve detects part movement using a whisker arm, which triggers the valve to open or close, controlling air flow in industrial applications.