Gas Appliance Regulation

Figure 1: A brass ball valve that can be used in a gas line.

Note: this article is applicable only for the EU market.

Regulation Update: On April 21st, 2018 the Gas Appliances Directive (GAD) became invalid and was replaced by the Gas Appliances Regulation (GAR). Any product produced after April 21st, 2018 that met GAD historically or will require a certification for usage in gas appliances, will need to meet the new GAR standards before being put on the European market.

GAR overview

GAR objectives

The GAR applies to appliances burning gaseous fuels used for cooking, heating, hot water production, refrigeration, lighting, or washing as long as they produce heat. It also covers fittings essential for the safe operation of these appliances (e.g., solenoid valves and ball valves). The regulation is designed to ensure that only gas appliances and fittings that are safe and meet the essential requirements outlined in the regulation are placed on the EU market and put into service.

Key aspects of the GAR

- Safety requirements: The GAR sets out essential requirements regarding the safety and performance of gas appliances and their fittings. These requirements focus on design and construction to ensure safe operation, protection against hazards, and providing necessary information through labeling and instructions.

- Conformity assessment: Manufacturers of gas appliances and fittings must carry out a conformity assessment procedure to demonstrate compliance with the essential requirements of the GAR. This involves internal production control, and in some cases, an examination of the appliance design or type by a notified body (an organization designated by an EU country to assess the conformity of certain products before being placed on the market).

- CE marking: Once compliance is confirmed, the manufacturer must affix the CE marking to the product, indicating that it meets the EU safety, health, and environmental protection requirements. The CE marking is a key indicator of a product's compliance with EU legislation. It allows the free movement of products within the European market.

- Responsibilities of economic operators: The GAR outlines specific obligations for various economic operators, including manufacturers, importers, and distributors, to ensure that only compliant products are placed on the EU market. This includes keeping technical documentation, ensuring the conformity of the production process, and responding to requests from national authorities.

- Market surveillance: Member states are required to monitor the market to ensure that only compliant products are sold within the EU. They have the authority to take corrective actions if non-compliant products are found.

Table 1: Appliance and fittings that must meet the GAR

| Type | Location | Exception(s) |

| Cooking |

|

|

| Heating |

|

|

| Hot water production |

|

|

| Refrigeration |

|

|

| Washing |

|

|

| Lighting |

|

|

| Fitting location |

|

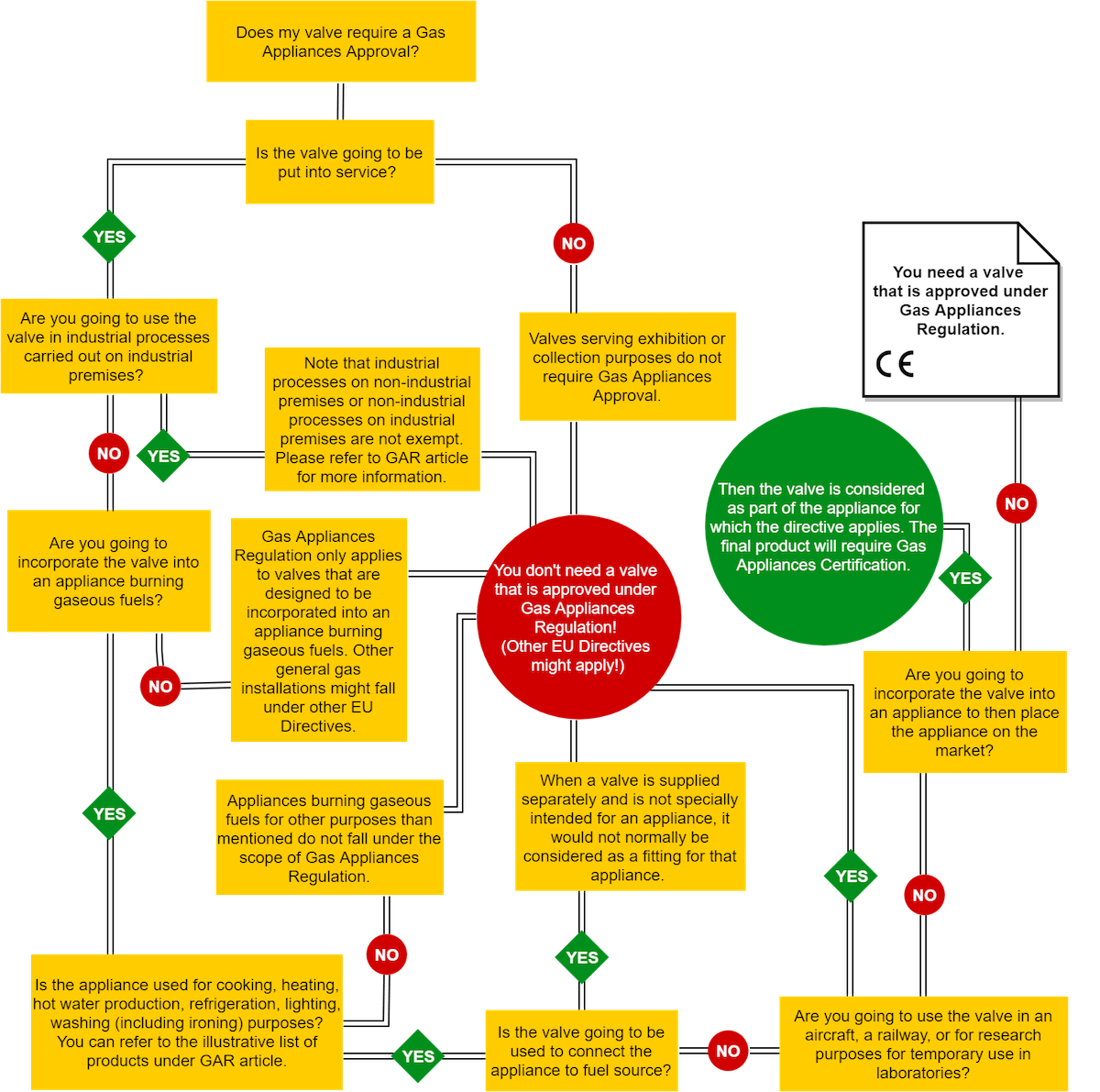

Does a valve need GAR approval?

Please utilize our flowchart below to see if your application requires a gas appliance approved valve. For further information, please see our notable exemptions below or contact our technical support for clarification.

Possible GAR exemption

Products may be exempt from the GAR for several reasons, primarily based on their intended use, design, or the specific nature of the product itself. Not all products fall within the intended scope or pose the same level of risk. Here are some reasons why a product may be exempt from the GAR:

- Industrial use: Appliances designed for industrial processes carried out on industrial premises are exempt. This is because such appliances are typically subject to specific safety protocols and regulations that are more appropriate for the industrial context.

- Professional use: Appliances intended exclusively for use in professional contexts, where they are operated by trained personnel, might be exempt. The rationale is that professional environments can ensure safety through specialized training and workplace regulations.

- Non-gaseous fuels: The GAR applies specifically to appliances designed with gaseous fuels. Therefore, this regulation does not cover appliances that operate exclusively on liquid or solid fuels.

- Prototype development: Prototypes developed for research and testing purposes that are not intended to be placed on the market may be exempt. This allows for innovation and development without the immediate constraints of regulatory requirements.

- Military or civil defense appliances: Appliances designed for military or civil defense applications are exempt from the GAR. These appliances are typically subject to different regulatory frameworks considering their specific use cases and environments.

- Custom-built appliances for experimental purposes: Appliances that are custom-built for a particular research project or experimental setup and not intended for mass production or commercial use may be exempt. This facilitates scientific research and experimentation.

- Specific types of gas equipment: The GAR does not cover certain types of gas equipment, such as gas meters, regulators, and devices intended for connection to or to form part of a gas transmission network. These items are regulated by other specific EU directives or regulations that better suit their operational and safety requirements.

Notified bodies

Notified Bodies are organizations designated by EU Member States to carry out conformity assessment tasks under various EU directives and regulations, including the GAR. Their role is to ensure that products comply with the relevant safety, health, and environmental protection requirements. Notified Bodies can be private or public organizations and are recognized by an identification number issued by the European Commission.

EN 161 & GAR

EN 161 is a European Standard that specifies the requirements and testing methods for automatic shut-off valves for use with gas and particular types of gas appliances. These valves are designed for use with gasses of the three family types (manufactured gas, natural gas, and liquefied petroleum gas (LPG). They are intended to ensure the safe operation of gas appliances by controlling the gas flow and shutting it off automatically under certain conditions to prevent accidents or leaks.

The association between EN 161 and the GAR is significant because compliance with EN 161 is one way manufacturers can demonstrate that their gas appliances or the automatic shut-off valves used within them meet the safety requirements outlined in the GAR. By adhering to the standards specified in EN 161, manufacturers ensure that their gas appliances are equipped with reliable automatic shut-off mechanisms that contribute to the overall safety of the appliance, thereby aligning with the GAR's objectives.

Repair & upgrade

Repairing or upgrading a product that falls under the Gas Appliances Regulation requires careful consideration of the regulatory implications to ensure continued compliance with the essential safety and performance requirements set out in the regulation. Whether for maintenance, repair, or upgrading purposes, any gas appliance or fitting modifications must not compromise compliance with the GAR. Here are key considerations and steps involved in repairing or upgrading a GAR product:

- Safety and performance: Any repair or upgrade must not adversely affect the safety and performance of the product. This means that the product must continue to meet the essential requirements of the GAR after any modifications.

- Technical documentation: Modifications may require updates to the product's technical documentation. Manufacturers or responsible parties must maintain detailed records of the design, manufacturing process, and conformity assessment procedures, including any changes made during repairs or upgrades.

- Conformity assessment: Significant modifications, especially those affecting the product's gas safety or functional aspects, may necessitate a new conformity assessment. This could involve re-evaluation by a Notified Body to ensure that the modified product still complies with the GAR.

Repair and upgrade process

- Use of approved parts: When repairing a GAR product, it's important to use parts that the manufacturer approves and that comply with the GAR. Using non-approved parts could compromise the appliance's safety and compliance with the regulation.

- Qualified personnel: Repairs and upgrades should be carried out by qualified personnel who are familiar with the GAR requirements and the specific product. This ensures that the work is performed correctly and safely.

- Manufacturer's guidance: Adhering to the manufacturer's guidance for repairs and upgrades is crucial. Manufacturers may provide specific instructions or kits for upgrading products, which are designed to maintain compliance with the GAR.

- Notifying authorities: In some cases, significant modifications to a product may require notification to the relevant regulatory authorities or Notified Bodies. This is particularly important if the modifications affect the product's safety features or intended use.

- CE marking: After any repair or upgrade, the product must still carry the CE marking, indicating its compliance with the GAR and other applicable EU regulations. If the modifications affect compliance, the CE marking cannot be legally affixed until conformity is re-established.