Preventing And Resolving Ball Valve Stem Leaks

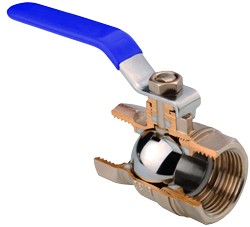

Figure 1: Ball valve sectional view

Ball valve stems can leak due to factors such as wear, corrosion, and improper installation, leading to inefficiencies and potential system failures in fluid control systems. These leaks can result in fluid loss, pressure drops, and increased maintenance requirements, impacting overall system performance. This article examines the underlying causes of ball valve stem leaks and presents effective strategies for their prevention and resolution. By implementing these solutions, the reliability and longevity of ball valve systems can be significantly enhanced.

Table of contents

- Leaks in a ball valve stem

- Ball valve stem leakage causes

- Repairing a leaking ball valve stem

- Preventing stem leaks

- FAQs

View our online selection of ball valves!

Leaks in a ball valve stem

Identifying the source of a leak in a ball valve can pose a challenge since several components can contribute to leaks. A few indicators can help determine if the stem is the source of the leak:

- Visible leakage: The stem packing prevents leaks in the stem area. If fluid leakage is visible in the stem region, the stem packing may be damaged or worn out.

- Difficulty turning the valve: A ball valve that is difficult to turn suggests an issue with the stem. The stem can be misaligned, damaged, or bent, preventing smooth operation and causing friction against the valve body; this can lead to wear and tear of the stem packing and other parts, resulting in leaks.

- Unusual sounds: Any odd sounds while turning the valve, such as grinding, squeaking, or scraping, indicates a problem with the stem. This may result from misalignment, damage, or worn-out stem packing, causing the stem to rub against the valve body.

Detecting stem leakage

Use the soap water technique to detect a leak in the stem region if it isn't visible. This method is commonly employed on gas lines.

- Remove the actuator or gear unit from the valve by unscrewing the bolts or nuts that hold it in place. This exposes the stem region.

- Apply soapy water to the stem region of the valve using a spray bottle or a brush.

- If there is a leak in the stem region, the soap will bubble up when the valve is under pressure and indicate the location of the leak. Look carefully for any bubbles forming around the valve stem or packing gland.

- Identify the location of the leak. Take appropriate measures to repair or replace the valve.

Ball valve stem leakage causes

Stem leakage can reduce the performance of the valve and the system it is in. Understanding stem leakage's causes is important for effective maintenance and repairs.

- Stem packing failure: Ball valves use stem packing to prevent leaks around the valve stem. Over time, the stem packing can become worn or damaged, causing it to lose its sealing ability and allowing fluid to leak out.

- Bent or misaligned stem: A bent or misaligned stem may not be able to turn properly, causing it to rub against the valve body and wear out the stem packing. This can also create gaps between the stem and the valve body, leading to leaks.

- Stem nut or bolt failure: The stem nut and bolt secure the stem. Loose or damaged nuts and bolts can cause the stem to move out of position, causing leaks.

- Improper lubrication: Lubricate the ball valve regularly to ensure smooth operation. The stem can become stiff or difficult to turn if not properly lubricated, leading to wear and tear on the stem packing and other components.

- Corrosion: Like other ball valve parts, the stem can corrode over time, especially if exposed to harsh chemicals or high temperatures. Corrosion weakens the stem, causing it to break or wear out. Use a valve with a stem and packing material that is resistant to corrosion and abrasion; this helps reduce the likelihood of stem leaks in harsh applications . Also, stem blockage due to debris like dirt, rust, and paint inhibits the valve from rotating in place. Read our article on corrosion-resistant ball valves for practical tips on reducing corrosion in ball valves.

- Operating conditions: High pressure and temperature systems can put additional stress on the valve stem and packing, causing leaks to develop over time. Using a valve with a stronger stem or a higher pressure rating can help to reduce the likelihood of stem leaks in high-pressure systems. Read our article on high-pressure ball valves for the design and selection criteria of ball valves working under high pressure.

Repairing a leaking ball valve stem

Repairing a leaking ball valve stem can be done efficiently and effectively with proper tools and techniques. Resolve the issue of a ball valve leaking at the stem by following these steps:

- Turn off and inspect the valve: Turn off the ball valve to stop the fluid flow through the valve. Inspect the valve to determine the source of the leak. Check the stem, stem packing, stem nut or bolt, and other components for damage, wear, or corrosion.

- Tighten the stem nut or bolt: Tighten the stem nut or bolt if it is loose. This helps to seal the valve and stop the leak. If the stem leak continues, tighten the gland nut (a component used to compress the packing material around the valve stem to create a seal and prevent leaks) until the leakage stops. Replace the stem if the leak continues.

-

Replace the stem packing and other components:

- Replace the stem packing if it is damaged. While replacing the packing, ensure that the valve is not under pressure. Replacing the stem packing while the valve is under pressure can be extremely dangerous, as it can cause the valve to suddenly open or close, resulting in serious damage. Also, if the valve is under pressure, it can cause the new stem packing to be improperly installed, leading to leaks.

- Remove all accessories, including the valve actuator, to access the stem packing.

- After loosening and removing the gland nut, remove the packing using a hooked wire.

- Ensure that the new packing is aligned and seated correctly.

- If any ball valve components are damaged or corroded beyond repair, replace them. This may include the stem, stem nut, bolt, or other components like the ball, seats, body, trim components (such as the packing, gasket, or o-ring), or other internal or external parts.

- Reassemble and test the valve: After making the necessary repairs, reassemble the valve according to the manufacturer's instructions. Ensure that all components are properly aligned and tightened to the appropriate torque. Turn on the fluid flow and test the valve for leaks.

Preventing stem leaks

A leaky stem can lead to safety hazards, environmental damage, and costly downtime. There are several preventative measures to reduce the likelihood of stem leaks in ball valves.

- Regular maintenance: Regular maintenance prevents leaks in ball valves. This includes inspecting the stem, stem packing, and other components for wear and tear, damage, or corrosion and cleaning or replacing the parts as needed. Regularly checking the stem alignment can help catch any issues early on and prevent them from causing leaks.

- Proper installation and stem alignment: Ensure the ball valve is installed correctly according to the manufacturer's specifications. Also, check if the stem is properly aligned and if the stem nut or stem bolt is tightened to the appropriate torque. Misalignment between the stem and valve body can cause wear and tear on the stem packing and other components, leading to leaks. Read our article on ball valve installation for more details.

- Lubrication: Regular lubrication of the stem and other moving parts is essential to ensure smooth operation and prevent wear and tear. Use a suitable lubricant as recommended by the manufacturer.

- Proper use: Ensure that the ball valve is used in a manner that does not put undue stress on the stem or other components. Avoid force, and operate the valve within its rated pressure and temperature limits.

- Stem extensions or protectors: Stem extenders, also known as stem extensions or stem risers, can be added to a valve stem to increase its length. In situations where the valve is located in a hard-to-reach location, adding a stem extender makes it easier for the operator to access the valve for routine maintenance and inspection. This increased accessibility helps identify and address potential stem leaks before they become more serious.

-

Rising stem: Rising stem ball valves have a unique cam system that rotates the ball as the stem moves up and down in a linear motion without rotating.

- The rising stem design allows the valve to be highly suitable for frequent operations while keeping routine maintenance to a minimum.

- The stem packing can be tightly fitted around the stem without being damaged by rotational motion.

- The stem's linear motion reduces friction and wears on the stem packing, which can help extend its life and reduce the risk of leaks.

- Rising stem ball valves can be designed with metal components coated or plated with plastic epoxy, which helps prevent corrosion and further reduces the likelihood of leaks.

FAQ

How to stop a stem leak on a ball valve?

To stop a stem leak on a ball valve, replace the stem packing or stem seals, tighten the gland nut, or repair or replace the valve stem.