Ball Valve Applications

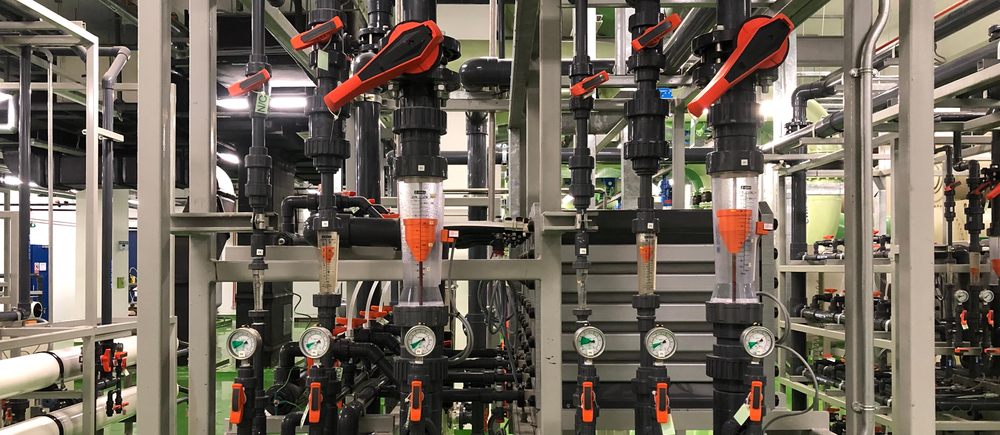

Figure 1: Ball valves in use in a water treatment plant

A ball valve is a quarter-turn shut-off valve that uses a rotary ball to control the flow of gas, compressed air, and various liquids. These valves allow the through-hole configuration to be blocked, open, or partially open to regulate the flow of liquid or gas. A ball valve is a common choice for several industrial and common household applications like showers and washing machines because of its air-tight sealing, ease of use, manual operation, and reliability. This article discusses common ball valve applications in various industries.

Table of contents

- What is a ball valve?

- Household equipment ball valves

- Ball valves and hose for gardening

- Refrigeration ball valves

- Ball valves in the oil and gas industry

- Ball valve advantages

- Ball valve disadvantages

- FAQs

View our online selection of ball valves!

What is a ball valve?

A ball valve is a shut-off valve that controls fluid flow by means of a rotating ball having a bore within. By rotating the ball by 90 degrees around its axis, the medium can flow through the valve, or it gets blocked. Ball valves are used in a wide range of applications, including both industrial and household applications like floor drains, showers, and washing machines.

Ball valve materials

The most common housing materials are brass, stainless steel, and PVC (PolyVinyl Chloride). The ball is usually made of chrome-plated steel, chrome-plated brass, stainless steel, or PVC. The seats are often made of teflon but could also be made of other synthetic materials or metals. Read our article on the chemical resistance of materials for more information on the compatibility of various materials with the chosen media of operation and the environment.

Ball valves are extensively used in various industries like food and beverage, transport, petrochemical, and agriculture due to their low response times and ease of operation. The common applications of ball valves are discussed below.

Household equipment ball valves

Ball valves are extensively used in residential plumbing systems to enable main water and branch shutoffs during leaks. They are also used in standard household devices like water taps, showers, heaters, and washing machines.

For example, a dishwasher is a device that rinses and cleans dirty dishes. A ball valve can be chosen as the water inlet valve of the dishwasher. A water inlet valve connects the dishwasher to the main water supply line. The valve is mounted within the dishwasher and opens when the device is on, allowing the flow of water into the device and stopping the water flow otherwise. Therefore, the ball valve chosen for a dishwasher must be compatible with water at all temperatures. To withstand high temperatures, the valve should have a PTFE (Teflon) or EPDM (Ethylene propylene diene monomer rubber) seal. Brass or stainless steel can be used as the housing material.

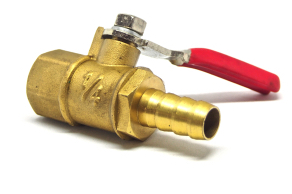

Figure 2: Ball valve used for compressors

Ball valves and hose for gardening

Ball valves can be used in a garden to meet various watering needs. These valves can be attached to garden hoses, watering tools, sprinkler lines, or faucets. Switch off the main water supply while installing the ball valve to the main water line. Connect one port of the ball valve to the main water supply. Screw the garden hose fitting to the other port of the ball valve. Turning the handle to open or close the valve can start or stop the water flow through the hose.

For compatibility with water, the fitting and ball valve housing can be made of brass or plastic (PVC), and the ball and seal can be made of EPDM. PVC has resistance to most chemicals and corrosion. Rotate the handle by 90 degrees to open or close the valve for manual ball valves. For pneumatic or electric control, choose a ball valve with ISO-Top flange.

To change any water attachments connected to the valve, turn off the water pressure by changing the valve handle to the OFF position. This is mandatory to avoid kinking of the hose.

The ball valve and the garden hose fitting can be purchased separately for a particular application. Specific models are available in a ‘combination pack’ offering both tools together, thus providing an easy installation process.

Figure 3: Garden hose connected to a ball valve

Refrigeration ball valves

Ball valves can be used as shut-off valves in refrigeration, commercial HVAC, and individual air conditioner units. The design, sealing material, and welding should support a safe construction that suits the most demanding requirements, like a high working pressure when operated with refrigerants like R410A. Read our article on solenoid valves for HVAC-R for more details on the refrigeration and air conditioning working processes and the valves required.

Refrigeration ball valves turn the refrigerant flow on and off to allow repairs or recharge the refrigerant. These valves must be compatible with common refrigerants like HFC, R22 (freon), R404A, R410A, HFO, and R290, to name a few. Brass can be chosen for the valve body. These valves are installed in suction, discharge, and liquid lines in air conditioning and refrigeration systems.

Ball valves in the oil and gas industry

Ball valves are commonly used as fluid shutoff valves in onshore and offshore oil and gas production facilities. They are also used in fuel gas system feeding furnaces. Ball valves are designed to control the flow of high-pressure gasses and liquids with minimal pressure drop. They have a very low response time which means they are quick to open and close, and these valves have a tight-sealing capability with low torque. Ball valves can be used in various remote locations within petrochemical industries as these valves are versatile and easy to operate and repair.

Ball valves are available in numerous styles like a reduced bore, full bore, v-port, floating-type, and true-union, making these valves highly versatile. A floating ball valve works better in a low to medium pressure pipeline, whereas a trunnion ball valve can be used in high-pressure conditions.

Ball valves are suitable for pigging. Pigging is the process of cleaning a gas pipeline where a device known as a pig travels through the pipeline. This process is not supported by certain valve types that do not allow the free travel of pig through the connected valve. For example, a butterfly valve has a rod running through its center that obstructs the path of a running pig rendering the valve incapable of pigging applications. A full bore ball valve lends itself to the pigging application. In an open state, the bore of the valve is parallel to the inlet and outlet ports; hence, there is no visual difference between the valve and pipe bores. In this way, a pig can have an unrestricted flow through a full bore ball valve unrestricted, thereby cleaning the bore of the valve along with the entire pipeline.

Ball valves are used primarily for low-pressure applications, where rubber seals can be used. For high pressure and high-temperature applications, choose a ball valve with a metal seat. Ball valves handling combustible and dangerous fluid media are provided with an emergency seat seal. These emergency seat seals are made of metal and are attached adjacent to the ball so that the ball can move against the metal seal in case the original soft seal catches fire. For maximum life and performance of the valve, choose materials like brass, aluminum, steel, or cast iron for the body. The packing material must be capable of lasting through a fire.

There are several standards for classifying devices for a hazardous environment like ATEX (Atmosphères Explosibles (EU), NEMA (National Electrical Equipment Manufacturers Association (USA), and IEC Ex (International Electrotechnical Commission Explosive (global)). While purchasing a valve for working with explosive fuels, make sure to check the marks of one of these standards on the valve. Ensure the valve has the appropriate IP rating for dust, liquid, moisture, and contact protection. This is particularly important when the ball valve is installed in harsh industrial environments for remote operation.

Ball valve advantages

- Leak-proof service

- Fast response time

- Rugged construction and long service life

- Low maintenance and compact design

- Cost-effective

Ball valve disadvantages

- Ball valves are not suitable for permanent throttling applications.

- In slurry-related applications, the suspended particles may settle and become trapped in body cavities causing abrasion, leakage, or valve failure.

FAQs

What is a ball valve in refrigeration?

Ball valves are used as shutoff valves, and these valves are commonly used in liquid and hot gas lines in refrigeration systems.

How does a dishwasher inlet valve work?

The water inlet valve fills the dishwasher with the required amount of water from the main water supply. The valve can be controlled electronically or through a timer.

What is the most common application for a ball valve?

Ball valves are commonly used in drinking water and gas applications.