V-Port Ball Valves

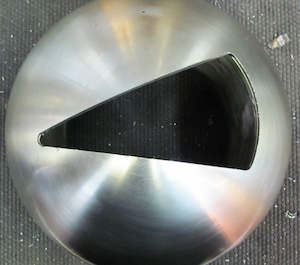

Figure 1: V-port ball valve

Note: At this time, Tameson does not supply V-port ball valves.

Ball valves are commonly used in industrial and residential piping systems to control the flow of liquids and gases. Ball valves are classified into full port, reduced port, standard port, and v-port ball valves based on their bore design and diameter. This article explores the design features of a v-port ball valve.

Table of contents

- Ball valve classification based on port size

- What is a v-port ball valve?

- How a v-port valve works

- V-notch ball valve design parameters

- Choosing a v-port ball valve

- Advantages of v-port ball valves

- V-port ball valve disadvantages

- V-port ball valve applications

- FAQs

Ball valve classification based on port size

Ball valves are quarter-turn valves used to shut off or pass fluids through piping systems. Ball valves have several styles tailored for specific functions. Depending on the port size, ball valves are categorized into the following types:

Full port ball valve

The bore of a full port valve is the same diameter as the inlet and exit pipes. As the size of the bore and pipes are similar, full port ball valves have no resistance to fluid flow. In this type of ball valve, the flow path is always straight.

Standard port ball valve

For a standard port ball valve, the diameter of the bore is smaller than the diameter of the inlet and outlet pipes. The diameter of the flow path through the ball valve is narrower on the interior. The standard port ball valve creates resistance to flow, increasing its fluid pressure. The flow path is usually straight.

Reduced port ball valve

The bore size in a reduced port ball valve is usually one pipe size narrower than the pipe. This creates a higher velocity when fluid is flowing through the valve.

V-port ball valve

Ball valves with either a v-shaped seat or v-shaped balls are called v-port ball valves.

Read our ball valve port designs article for more details on the characteristics of each port type.

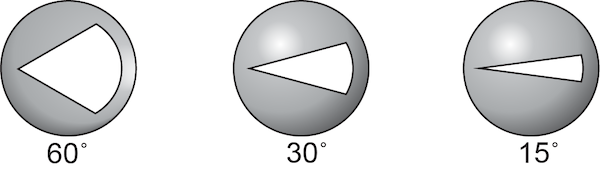

Figure 2: V-shaped bore in a v-port ball valve

What is a v-port ball valve?

A v-port ball valve is a control valve with a v-shaped seal or v-shaped ball. The ‘v’ shape allows for better fluid control. The molded v-bore differentiates the v-port ball valves from other ball valve types. The v bore is available in either a 15⁰, 30⁰, 45⁰, 60⁰, or 90⁰ angle as seen in Figure 3.

V-port ball control valves are generally preferred for fluid control since they produce linear flow characteristics. A v-port ball valve's flow characteristics are different from that of standard port ball valves. The fluid flow through a v-port ball valve increases linearly with an increase in shaft rotation. V-ball control valves have high strength to withstand the high velocity of fluids flowing through the valves.

Figure 3: Common v-port profiles

How a v-port valve works

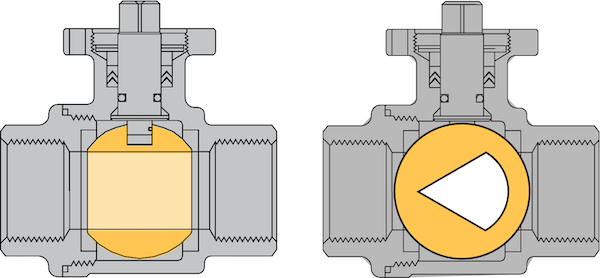

The v-port ball valve uses a ball with a v-shaped bore. The valve can be operated manually using a handle or automatically using an actuator. The valve opens or closes by rotating the handle, which simultaneously rotates the ball. When the ball is rotated to an open position, the small end of the v bore opens first. This facilitates stable flow control at this point. Spinning the ball opposite closes the valve (see Figure 4). Opening or closing the valve requires a quarter turn on the handle to align the bore with the pipes.

Figure 4: V-port ball valve open (left) and closed (right) configurations.

V-notch ball valve design parameters

A V-notch ball valve is a ball valve that has a V-shaped notch cut into the ball. The valve's body is stainless steel or carbon steel, while the stem is PEEK or metal. A V-notch ball valve can work in a temperature range of between -46⁰C to 343⁰C.

Choosing a v-port ball valve

- Pressure rating: Make sure the valve you choose has the appropriate pressure rating for your application.

- Valve size: The valve should be the proper size and fit into the piping system.

- The material used: Choose a v-port ball valve made from materials compatible with the medium being transported. Read our article on the chemical resistance of materials for more details.

- Temperature rating: Ensure that the valve can withstand the application temperature.

- Connection type: Choose a valve with a suitable connection type for the application, like flanged, welded, or threaded.

Advantages of v-port ball valves

Precise flow control

The openings of v-ball control valves are available at different angles (15⁰, 30⁰, 60⁰, and 90⁰), which offer equal percentage flow characteristics. Rotating the ball anywhere between 0⁰ and 90⁰ helps achieve the desired flow rate. Precise flow control allows for better accuracy of fluid flow in piping systems.

Low pressure drop

The flow path of fluids through the V-port ball valves is usually straight. The straight flow minimizes pressure drop across the valve. Compared to other control valves, v-port ball valves have a relatively high flow coefficient (Cv or Kv). The high Cv (or Kv) value makes it possible to use smaller V-ball control valves to achieve the same flow rate as other larger control valves.

High shut-off pressure

A quarter turn on the ball is sufficient to open or close a v-port ball valve. The ease in operation makes it possible to open or close the valve at higher working pressure. Hence, lower torque actuators are ideal for its operation.

Bubble tight shut-off

The principle of floating ball used in V-ball valves helps in providing a bubble-tight shut-off and aids in flow regulation. When it closes, the ball presses against the seat by the upstream pressure. This provides an air-tight seal. The bubble-tight seal makes V-port ball valves suitable for gas applications.

V-port ball valve disadvantages

- V-port ball valves are more expensive than other types of ball valves.

- V-port ball valves may be irreparable if damaged.

V-port ball valve applications

V-port ball valves have applications where precise control of flow is required. They are also preferred in oil and gas industries because of their bubble-tight shut-off. Other sectors that have applications for V-port ball valves include:

- Food and beverage processing

- Water treatment

- Chemical treatment and storage

- Pharmaceuticals, etc.

FAQs

How can I maintain v-port ball valves?

V-port valves require less maintenance. You should always keep it greased and inspect it for faults or leaks regularly.

What is the main difference between v-port valves and standard ball valves?

The ball of a v-port ball valve has a v-shaped notch in the center. The ball of a standard ball valve has a spherical notch.

What is the price of a v-port ball valve?

The price of a V-port ball valve depends on its size, material, and design. Other customer requirements also contribute to the price.