Characterized Ball Valve

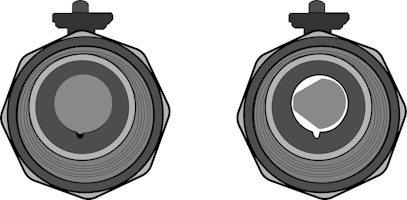

Figure 1: Belimo characterized control valve

Characterized ball valves are modified ball valves designed specifically for fluid control. The bore shape in a characterized ball valve can be customized to a 'V,' 'U', or parabolic shape to suit the application's specific requirements. They are used for controlling and modulating flow, offering stability and precision. Characterized ball valves are particularly useful in applications like HVAC systems, where maintaining consistent temperatures is crucial for comfort and energy efficiency. Their main features are:

- Equal percentage flow characteristic: A characterized ball valve controls the flow of liquid or gas consistently as it opens and closes, maintaining a steady temperature or pressure.

- Excellent control stability: The special disc inside the valve helps control flow smoothly and evenly. This can increase the lifespan of the actuator.

- Eliminates multiple pipe reduction: Certain systems might need to use smaller pipes to control flow as smaller pipes inherently restrict flow, which can help achieve a certain level of control. However, using smaller pipes can also lead to increased pressure drops and energy losses. A characterized ball valve can precisely control flow rates without solely relying on smaller pipes.

Read our v-port ball valve article for more information on the design and applications.

View our online selection of ball valves!

Standard ball valve vs characterized ball valve

Standard ball valves

Ball valves are excellent for on/off applications. However, they are not designed to modulate or regulate the flow steadily. They allow large fluid flow (high Cv or Kv) relative to their size, making them unsuitable as modulating control devices. This makes it difficult for ball valves to maintain or modulate a consistent temperature, as they can't steadily control the amount of hot or cold medium passing through. For example, for a ball valve that regulates hot water to control the temperature of a system, the abrupt changes in flow could lead to sudden temperature fluctuations, making it difficult to maintain a stable temperature.

In a regular ball valve, the bore through the ball is typically round; it aligns with the pipeline when the valve is fully open (Figure 2 left). When the valve is partially open, the flow path becomes restricted by the circular shape of the bore, meaning even a slight movement of the valve can result in a significant change in the flow rate.

Characterized ball valve

Characterized ball valves have specialized bore shapes for more controlled and predictable flow characteristics (Figure 2 right). The characterized ball valve combines the shut-off capabilities of a ball valve with a characterized disc, ensuring an equal percentage flow characteristic. An equal percentage flow characteristic implies:

- A flow behavior where each increment of valve position change delivers a constant percentage change in flow rate, providing precise and stable control over wide load changes.

- A steady thermal output (how hot or cold something gets) that varies linearly based on how much the valve is opened.

A characterized ball valve allows for greater control and precision in managing the flow rate, especially under varying load conditions. This improves system efficiency, stability, and responsiveness, making it ideal for applications with large load changes.

Figure 2: Normal ball valve disc (left) and the special disk pattern in a characterized ball valve (right).

Standard and characterized ball valve flow profiles

Standard ball valve

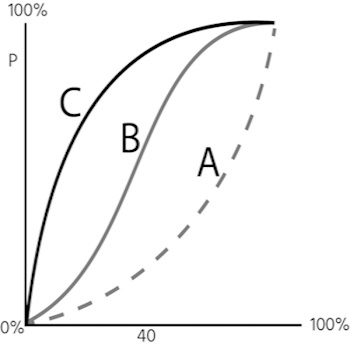

Figure 3: The flow profile and heat emission in a standard ball valve: ideal flow (A), standard ball valve flow (B), and resulting heat output in a standard ball valve (C)

Figure 3 shows the flow and heat emission relationship when a standard ball valve opens incrementally.

- A: Ideal flow characteristic. The flow and heat emission do not increase abruptly with changes in the valve opening.

- B: Standard ball valve flow characteristics

- C: Resulting heat output in a standard ball valve

The resulting heat does not vary linearly (increases abruptly) with the valve opening (flow) degree. For example, the heat output is 'P' in a valve that is 40% opened.

Characterized ball valve

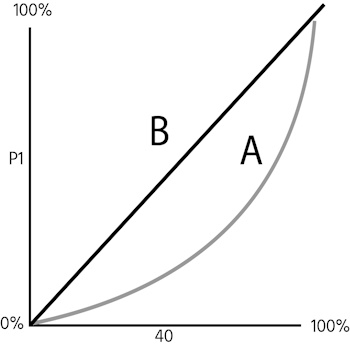

Figure 4: The flow profile and heat emission in a characterized ball valve: a characterized ball valve's flow profile (A) and linear heat output (B)

Figure 4 shows the flow and heat emission relationship when a characterized ball valve opens incrementally.

- A: A characterized ball valve's equal percentage flow profile

- B: Linear heat output

In a characterized ball valve that is 40% opened, the resulting heat dissipation is P1, which is much less than P (in the case of a standard ball valve). The resulting heat output varies linearly with the degree opening (or flow).

Characterized ball valve vs globe valve

The main advantage of a globe valve over a standard ball valve is its superior flow control capability. The Cv values of characterized ball valves match those of globe valves of the same size, meaning they can control flow as effectively. However, characterized ball valves have the following advantages over globe valves:

- Higher pressure resistance: Characterized ball valves can withstand higher pressure than globe valves of similar size. This is due to their streamlined design, which minimizes pressure drop and enhances structural integrity.

- Leak-proof: Unlike globe valves, characterized ball valves offer a leak-proof seal, which allows a small amount of leakage and low-pressure drops.

FAQs

What is a characterized ball valve?

A characterized ball valve is a special type with a shaped disc or insert to achieve more precise flow control or alter the valve's flow characteristics.

When should I use a characterized ball valve?

Use a characterized ball valve when you need precise flow control or when you wish to customize the valve's flow characteristics.