Types of HVAC Fittings

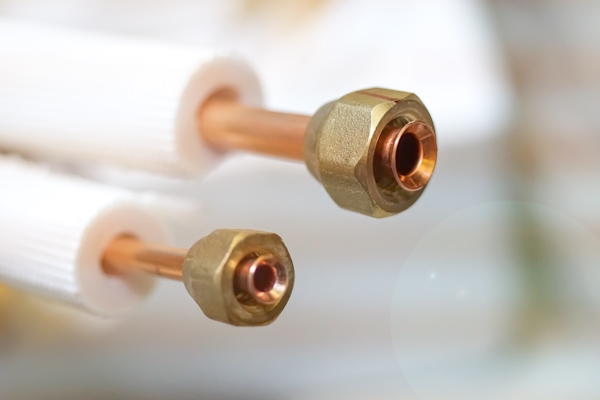

Figure 1: HVAC fittings for a chilled water control unit of an air conditioning system

HVAC fittings are integral components in heating, ventilation, and air conditioning systems by ensuring a good flow of air and water throughout the system. A complete understanding of the various types of HVAC fittings, including HVAC pipe fittings, is necessary for anyone involved in installing or maintaining these systems.

HVAC fittings are typically made from robust materials like stainless steel, brass, and copper that can withstand high pressure and temperature variations. This ensures their longevity and durability, even under challenging operating conditions. Furthermore, HVAC fittings come in various sizes and designs to ensure compatibility with various HVAC system designs. This article serves as a guide to the different types of HVAC fittings and their specific applications.

HVAC duct fittings

HVAC duct fittings are critical in ensuring efficient airflow through a ductwork system. They are suitable for pressure and temperature changes and are often made from durable materials like galvanized steel or plastic. This durability ensures the fittings can last long and resist wear and tear.

Their design facilitates smooth direction changes in the ductwork, reducing turbulence and maintaining airflow efficiency. This ensures the HVAC system can deliver optimal performance, providing the desired temperature and air quality in a building. Additionally, their flexibility allows them to accommodate various duct layouts, making them suitable for residential and commercial applications.

Figure 2: Duct fittings come in various shapes and sizes

HVAC press fittings

HVAC press fittings are designed for quick and easy installation, reducing labor time and costs. They use a press technology that provides a tight, leak-proof seal, thereby reducing the risk of air leakage and improving the system's energy efficiency. Furthermore, using press fittings for HVAC reduces the need for welding or soldering, minimizing fire risks and ensuring safer installation. These fittings are often used in closed-loop hydronic heating systems, where a leak-proof and secure connection is required for the circulation of water or other fluids.

Figure 3: A copper reducing press fitting

HVAC push fittings

The primary appeal of push fittings (both push-on and push-in) lies in their ease of installation. They simply push together, requiring no special tools, welding, or soldering, which reduces installation time and cost. This feature also minimizes potential installation errors, ensuring a secure and efficient connection. The tight seal they provide helps to prevent air leaks, promoting the energy efficiency of the HVAC system. Finally, push fittings are easily adjustable and can be removed and reused, offering flexibility during maintenance or system alterations. They can be used for connecting refrigerant lines in split-system air conditioners or for water lines in some heating systems where quick assembly and disassembly are beneficial.

Figure 4: A stainless steel push-in fitting (left) and stainless steel push-on fitting (right).

HVAC flare fittings

HVAC flare fittings utilize a unique design with a flared end, creating a wider surface area for the mating connector. This design ensures a tight and secure seal, minimizing leaks and maximizing the efficiency of the HVAC system. Installing flare fittings requires precision and skill, as the flared tubing needs to be created accurately to ensure a proper fit. However, once installed, they offer a reliable and robust connection that can be easily disassembled and reassembled during maintenance without any damage. Flare fittings are used in HVAC systems where high-pressure gas is present, such as in connections for refrigerant lines in air conditioning systems.

Figure 5: Flare copper pipe fittings for an air conditioning system

HVAC compression fittings

Compression fittings are known for their ease of installation and disassembly. They do not require soldering, making them a time-saving and convenient option. This feature also reduces potential safety hazards associated with welding or soldering. One of their main qualities is the tight seal they provide. The compression of the fitting onto the pipe creates a strong, leak-proof connection, enhancing the efficiency of the HVAC system by preventing air leaks. Moreover, they can be easily adjusted, removed, and reused, providing flexibility during maintenance or system modifications. These are often used in refrigerant lines, for instruments, or for connections to pressure switches and gauges.

Figure 6: A PP compression fitting

HVAC pneumatic fittings

Pneumatic fittings ensure the smooth operation of pneumatic systems in an HVAC system. Pneumatic systems in HVAC use compressed air to control heating, cooling, and airflow. When room temperature changes, the thermostat adjusts air pressure, which triggers controllers. These controllers regulate the air sent to actuators or valves. These devices then manage air or water flow in the system, maintaining the desired temperature and air quality. These fittings connect the control air lines and are used in the control systems of larger commercial or industrial HVAC systems, where air is used to signal thermostats, actuators, dampers, and valves.

Figure 7: A brass air coupling

FAQs

What are fittings in HVAC?

Various types of fittings are used in HVAC, ranging from fittings for air ducts to fittings for refrigerant heat exchangers.

What is a duct fitting?

A duct fitting can be one of many shapes and sizes and is used to connect air ducts in an HVAC system.