Push-on Fittings

Figure 1: A plastic tee push-on fitting

Push-on fittings, or push-fit fittings, connect multiple tubes or hoses in a system. The fittings' specific design makes it fast and simple to create strong and lasting air-tight connections. This article covers the design and working of these fittings, how they are commonly used, and how to select them for an application.

Design and operation principle

Push-on fittings have the following important components:

- Body: Pipes and tubes enter each side of the push-on fitting's body.

- Collet: The collet contains stainless steel teeth that press into the tube.

- O-ring: An o-ring for each port provides effective sealing. These o-rings are typically made of NBR or EPDM.

- Screw cap: The screw cap spins to provide or relieve compression on the collet.

The following steps describe how a push-on fitting works:

- The tube, plastic or copper, needs to be cut square and properly deburred. If the edge of the tube is not square, it will not sit properly in the fitting. If it is not deburred, it can damage the o-ring. Plastic tubes can use pipe inserts for better sealing and structural support.

- Determine the length of the tube that will sit inside the fitting. Mark that length from the tube's edge. The mark should nearly or completely go into the fitting's port to ensure the tube is fully installed. If the tube is not entirely in the fitting, leaking can occur.

- The outside of the collet (the side that the tube first enters) has a slightly larger diameter than the tube. The opposite side of the collet has flexible legs that widen when the tube passes through them. This allows the tube to slide in and out of the collet easily.

- The tube slides past the o-ring, which creates an effective seal against leaking.

- Once the tube has fully entered the push-on fitting, rotate the screw cap to close the fitting. When the screw cap rotates towards closing, it pushes down on the collet's legs. This drives the stainless steel teeth into the tube, making it impossible to pull the tube out of the fitting.

- If the tube needs to be removed, unscrew the screw cap and push on the outside edge of the collet. This releases the stainless steel teeth, and the tube easily slides out.

Applications

Push-on fittings are designed specifically for plastic tubes and copper pipes.They are suited for plumbing systems such as potable water, hydronic heating systems, irrigation, and water heaters. Since push-on fittings are easy and fast to connect, they are especially suitable for larger applications that require many fittings.

Disadvantages

Push-on fittings are not suitable for every application. For example, they cannot be used with oil or gas and they are not recommended for use with compressed air. Also, push-on fittings are not as aesthetically pleasing as copper fittings, which typically only matters in exposed pipe applications. Lastly, since they have stainless steel teeth in the collect, they cannot properly grip harder materials such as brass, bronze, stainless steel, and iron.

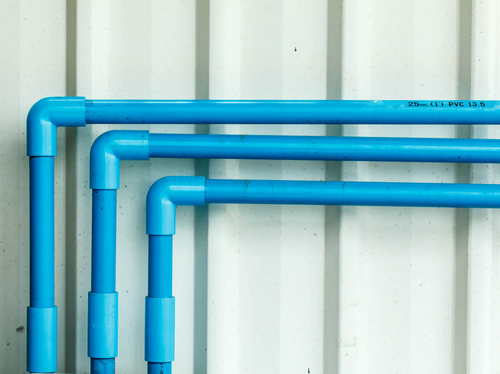

Figure 2: Plastic tubes for potable water.

Selection criteria

To select the appropriate push-on fitting for an application, consider the following criteria:

- Material: Ensure the fitting's material is compatible with the tubing or hose used. Common fitting materials are brass, stainless steel, and plastic.

- Size: The push-on fitting's port should be slightly larger than the tube or hosing.

- Pressure rating: Ensure the fitting's max operating pressure rating can handle the application's operating pressure.

- Temperature: Ensure the push-on fitting's material can withstand the application's temperature range.

- Flow requirements: Ensure the fitting can meet the application's flow requirements.

FAQs

Are push-on fittings good?

Push-on fittings can create strong and lasting connections like other types of fittings can. Their main advantage, though, is that they are quick and easy to install.

Do push-on fittings leak?

If a push-on fitting leaks, it's likely due to the tube not being cut square and properly deburred before being inserted into the fitting.