Needle Valves vs Ball Valves

Figure 1: A 1/4" brass ball valve (left) and a 1/4" brass needle valve (right)

Needle valves and ball valves are two of the most common types of valves used for flow control in piping systems. Whether the setup is a simple media transport system or a complex, multi-step system with automated controls and monitoring, the choice of valve plays a significant role in ensuring the system's efficiency, safety, and longevity. This article overviews the characteristics, advantages, and disadvantages of needle valves and ball valves, helping readers make an informed decision for their specific application.

Table of contents

View our online selection of ball valves and needle valves!

Ball valve and needle valve differences

Learn more about each type of valve in our ball valve overview and needle valve overview articles.

Table 1: Ball valve and needle valve differences.

| Factor | Ball valves | Needle valves |

| Flow control precision | Quick on-off control but lack precision for fine adjustments | Precise flow control, ideal for applications requiring fine-tuned adjustments |

| Operation speed | Quick quarter-turn operation for rapid state changes | Require multiple turns to fully open or close, making them slower to operate |

| Mixing applications | Ball valves, specifically 3/2-way ball valves, are suitable for mixing applications | Needle valves are typically designed for one-way flow control and not mixing applications |

| Maintenance and durability | Low maintenance with fewer internal components | Durable and reliable, even in demanding environments, but may require more maintenance due to precision components |

| Visual status indication | Handle position clearly indicates open or closed status | Open or closed status is not easily determined by visual inspection |

What is a ball valve?

Ball valves are named for their ball-shaped flow control element. The ball has a channel through its center, which aligns with the flow path when the valve is open and blocks the flow when rotated 90 degrees. This quarter-turn operation makes ball valves ideal for applications requiring quick on-off control.

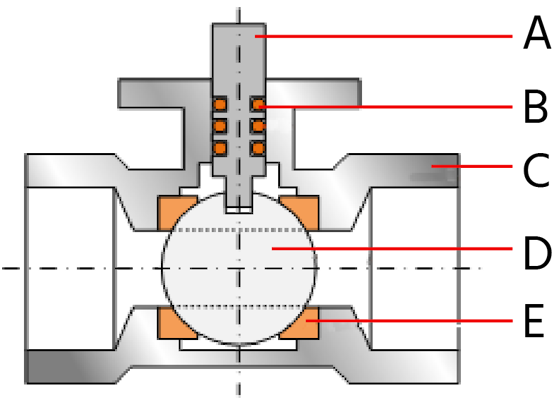

Figure 2: Ball valve diagram: stem (A), o-rings (B), housing (C), ball (D), and seat (E).

Advantages

- Ease of use: The position of the handle clearly indicates whether the valve is open or closed.

- Low maintenance: With fewer internal components, ball valves require minimal cleaning and maintenance.

- Cost-effective: Generally inexpensive, making them a popular choice in various industries.

- High flow rates: Full port ball valves maintain constant, unrestricted flow with minimal pressure drops.

- Durability: Suitable for high-demand applications, including those in agriculture, construction, HVAC, manufacturing, mining, and oil and gas. Learn more in our article about ball valve applications.

Disadvantage

Ball valves are not suitable for applications requiring fine flow control or extended throttling.

Common applications

- Oil and gas: Ball valves provide a tight seal and are capable of handling high-pressure and high-temperature conditions, which are common in the oil and gas industry. Their durability and reliability make them ideal for controlling the flow of crude oil, natural gas, and other hydrocarbons.

- Agriculture: In agricultural applications, ball valves are used for irrigation systems and fluid control. They are suitable because they offer quick shut-off capabilities, are easy to operate, and can handle a variety of fluids, including water, fertilizers, and pesticides.

- HVAC systems: Ball valves are used in HVAC systems for controlling the flow of water, refrigerants, and air. They are suitable because they provide a reliable seal, are easy to operate, and can handle the pressure and temperature variations typical in heating, ventilation, and air conditioning systems.

- Manufacturing: In manufacturing, ball valves are used for controlling the flow of various liquids and gasses in production processes. They are suitable due to their durability, ability to handle high pressures and temperatures, and their quick and easy operation, which is essential for maintaining efficiency and safety in industrial environments.

- Mining: Ball valves are used in mining operations for controlling the flow of slurries, water, and other fluids. They are suitable because they are robust, can handle abrasive materials, and provide a tight seal to prevent leaks, which is crucial in harsh mining environments.

- Marine and seawater environments (with stainless steel variants): Ball valves made of stainless steel are particularly suitable for marine and seawater environments because they are resistant to corrosion caused by saltwater. Their durability and reliability ensure long-term performance in harsh, corrosive conditions typical of marine applications.

Figure 3: Ball valves used in refrigeration systems

What is a needle valve?

Needle valves feature a needle-shaped plunger controlled by a threaded, rotating stem mechanism. This design allows for precise control of the flow rate, making needle valves ideal for applications requiring fine adjustments.

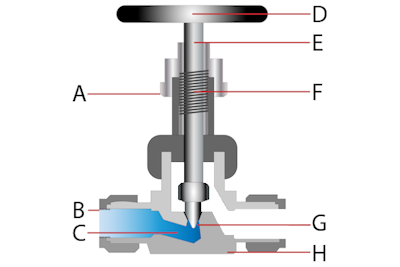

Figure 4: Needle valve cross-section view and components: packing nut (A), port connection (B), orifice (C), handle (D), stem (E), threads (F), tapered end (G), and valve housing (H).

Advantages

- Precision control: The fine-threaded stem allows for precise adjustments, making needle valves ideal for applications requiring accurate flow regulation.

- Long lifespan: Engineered for durability and reliability, ensuring consistent performance even in demanding environments.

- High pressure drop capability: Effective in applications where a significant reduction in pressure is needed, aiding in process measurement and control tasks.

Disadvantages

- Slow operation: Requires multiple turns to fully open or close, making rapid state changes difficult.

- Flow restriction: The small passage flow between the seat and needle limits the valve to low flow rates.

- Difficult to gauge: The open or closed status is not easily determined by visual inspection.

Common applications

- Chemical processing: Needle valves maintain the correct chemical reactions and concentrations.

- HVAC systems: They provide fine adjustments to flow rates, ensuring optimal performance and energy efficiency in HVAC systems.

- Manufacturing: Needle valves maintain consistent quality and precision in manufacturing processes.

- Petrochemicals: Needle valves offer safe and efficient handling of petrochemical products.

- Pharmaceuticals: Needle valves ensure precise dosing and flow control, maintaining the purity and consistency of pharmaceutical products.

- Automatic combustion control systems: Needle valves provide fine control over fuel flow, which is necessary for maintaining optimal combustion efficiency and safety.

- Fluid power systems: Needle valves enable precise control of hydraulic and pneumatic fluid flow, which is critical for the accurate operation of fluid power systems.

- Gas bleeder lines: Needle valves allow for safe and efficient removal of trapped air or gas.

- Metering systems: Needle valves provide accurate measurement and dispensing in metering systems.

- Vacuum systems: Needle valves offer fine control over vacuum levels, which is necessary for maintaining the desired vacuum conditions in various applications.

Figure 5: Needle valves used to transport crude oil at a processing station

FAQs

What is a needle valve?

A needle valve is a type of valve used to precisely control the flow of fluid in a piping system.

What is a ball valve?

A ball valve is a valve that uses a spherical ball to control the flow of fluid through it.

What is the difference between a needle valve and a ball valve?

A needle valve offers precise flow control, while a ball valve provides quick shutoff and on-off control.

When should you use a needle valve over a ball valve?

Use a needle valve for precise flow control and a ball valve for quick shutoff and on-off control.