Push-in fittings

Figure 1: Pneumatic push-in fittings

Pneumatic push-in fittings, also known as push to connect fittings, offer a leak-proof way to effortlessly connect hoses in your compressed air system. These fittings can have between 1-6 inlet/outlet ports or may include additional features like an integrated pressure gauge or silencer. This article covers the features, installation, and selection criteria of push-in fittings.

Table of contents

- Pneumatic push-in fitting installation

- The pros and cons of using push-in fittings

- Normal vs unequal fittings

- Selection criteria

- Applications

- Functional combinations

- Connection points

Check out our online selection of push-in fittings

Pneumatic push-in fitting installation

How to install pneumatic push-in fittings

The hose is easy to install by pushing it into the release ring-end of the fitting until it stops. The internal lock claws will automatically clamp around the hose for an immediate and secure connection.

How to uninstall pneumatic push-in fittings

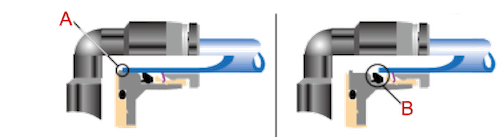

Push the release ring inward towards the fitting to disengage the lock claws and pull back on the tubing to remove it. The opposite end may be another push to connect fitting, threaded male, threaded female or a threaded male with an inner hex-type connection. The threaded connections usually have a pre-applied thread lock coating. The tube must be fuller inserted for a proper seal, as seen in (Figure 2 labeled A). Figure 2 point B shows an incomplete insertion of the tube, creating a leak in the seal.

Figure 2: Proper tube installation (A) and incomplete insertion (B).

The pros and cons of using push-in fittings

Pros

- Push-in fittings come with a quick release system which allows for simple and easy installation by hand, eliminating the need for tools and adhesive. Due to the ease of connecting and disconnecting air lines, it allows for frequent changing of air lines at a low cost.

- Push-in fittings are offered in a wide range of tube sizes, connections, and thread combinations to suit the desired outcome.

- Tameson fittings are RoHS compliant.

Cons

- Push-in fittings require firmer tubing with harder walls to resist being damaged by the internal claws. Firm tubing will be less flexible; therefore, it may not be suitable for systems where hoses will be routed around tight turns. If flexible tubing is desired, we recommend using hose tail barbed fittings instead of push-in fittings. Nylon, Polyethylene (PE), or Polyurethane (PU) tubing material is ideal for push-in fittings. It is also best suited for pneumatic (air) applications; however, it can be used for water applications.

Normal vs unequal fittings

Some fittings are available in normal or unequal variations. Normal fittings use the same diameter across all inlet and outlet ports whereas unequal fittings have ports with different diameters (larger or smaller) to connect different sized hoses.

Selection criteria

Pneumatic fittings should be incorporated into a system that requires connection hoses together. It is advised to keep things simple to ensure no significant pressure drop is induced. For example, don’t use a 90-degree elbow if a straight fitting is possible because the elbow will create an unnecessary pressure loss. Other considerations include:

- Operating pressure: Most fittings have a maximum operating pressure of 1.0MPa, but the pressure should be kept below this level to ensure safe operation.

- Operating temperature: Fittings contain o-rings and plastic parts that may become ineffective if using hot air or if the system is placed in a hot environment.

- Special environments: medical and food industries may require fittings with a special rating or material classification.

Applications

Push-in fittings are used in all types of compressed air systems, but are most commonly used in applications having pneumatic cylinders, tools, and equipment. They can be used for water applications, but extra measures have to be taken (controlled surge pressure, water compatibility, insert ring, etc.) The push on connection method allows for rapid changing of components, so it is ideal if you have one air source for multiple tools that can be exchanged out.

Functional combinations

Functional combination push-in fittings have additional features that may be useful to your application. Common additional functional combinations are:

- Flow control silencer to control the speed of air cylinders by choking the flow in one direction and muffling the sound

- Pressure gauge to read the line pressure

- Pressure regulator to limit the line pressure

- Check valves to ensure one directional flow

- Stopcock to externally control or stop the flow

Connection points

Fittings can have multiple connection points ranging from one to six connections. All fittings have at least one port as a push-in fitting (excluding plugs). How they route the air (straight, elbow, etc.), normal vs unequal, and other connection port methods (plug-in, threaded, etc.) make the differences in types.

One connection

These fittings have one connection port, so they end the flow of the air.

Plug and cap fitting

Plug and cap fittings are used when the flow of air needs to be temporarily terminated or capped. A cap (Figure 3 left) is used to terminate a pneumatic hose with a plug-in fitting. A plug (Figure 3 right) is used to seal a pneumatic push-in fitting and is installed/uninstalled in the same manor.

Two connections

Two connection fittings have a single push-in type port and a single threaded (male or female) or push-in type secondary port. The air flows from the inlet port to the outlet port.

Straight fitting

Straight fittings connect a hose in a straight line with a male or female threaded secondary port.

Inner hex straight fitting

Inner hex straight fittings have a male threaded secondary port and an inner-hexagonal connection. Inner hex straight fittings have a male threaded secondary port to connect it to a valve and/or a component. The inner-hexagonal can be tightened after the threaded connection is made and a hex key can come in from the push-in fitting side to tighten the threads.

Elbow fitting

Elbow fittings connect hoses at 90 or 45-degrees to change the direction of air flow. They have a male or female threaded secondary port. Normal elbows have arms that are the same length, whereas long elbows will have one longer arm.

Union straight fitting

Union straight fittings have a push-in type connection at each end to connect two hoses in a straight line. Unequal union straight fittings have different diameter ports to connect hoses of different sizes.

Union elbow fitting

Union elbow fittings connect two hoses and has a 90-degree bend to it. Each port has a push-in type connection.

Plug-in straight fitting

Plug-in straight fittings connect hoses in a straight line, whereby, one port uses a push-in type connection and the secondary port uses a stem or “plug-in type connection. Typically, the stem is inserted into an existing push-in fitting.

Plug-in elbow fitting

Plug-in elbow fittings connect hoses at 90-degrees using push-in and plug-in type connection ports.

Three connections

Three connection fittings have two push-in type ports and one threaded or another push-in type port. The fitting can have either two inlets and one outlet to increase pressure, or one inlet and two outlets to decrease pressure and make two air flows.

Union Tee fitting

Union Tee fittings form a “T shaped junction to connect three equal diameter hoses using a push-in type connection at all ports. Unequal Union Tee fittings are also available to connect a smaller diameter hose to two larger diameter hoses.

Union Y fitting

Union Y fittings form a “Y shaped junction to connect three equal diameter hoses using a push-in type connection at all ports. Unequal Y fittings are also available to connect a larger diameter hose to two smaller diameter hoses.

Four to six connection points

Push-in fittings are also capable of having more connection points, but typically no more than 6. A few examples of fittings with more connections are double “Y, triple “T, or cross fittings. These fittings are for special applications, but can help reduce overall fittings to feed 1 input line and to multiple outputs.