Vacuum suction cup

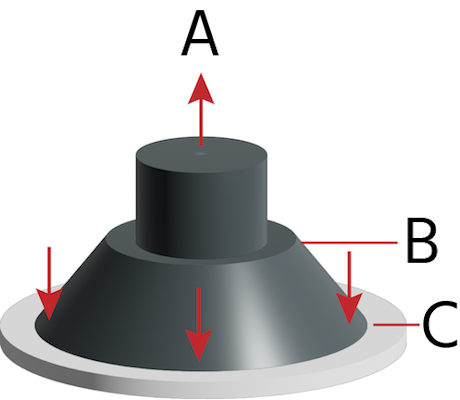

Figure 1: Vacuum suction cups

A vacuum suction cup is a device used in a vacuum system to grip and move objects for pick-and-place applications. These devices operate in conjunction with a vacuum generator to lift objects. They are usually made up of silicone, polyurethane (PUR), chloroprene (CR), or nitrile (NBR) and are available in various sizes and designs with different holding capabilities.

Table of contents

- Operating principle

- Types of vacuum suction cups

- Additional components

- Selection criteria

- Calculating the suction cup diameter

- Applications

View our vacuum suction cup selection here!

Operating principle

Vacuum suction cups work as a gripper in manual or automatic handling applications and use differential pressure to operate. It consists of two parts: the suction cup and the connecting element. The suction cup is the component that comes in direct contact with the workpiece. As the atmospheric pressure acting against the suction cup becomes greater than the pressure between the cup and the workpiece, the vacuum suction cup is attached against the workpiece. To achieve this pressure difference, the suction cup is attached to the vacuum generator. This vacuum generator helps in evacuating the air between the surface of the suction cup and the workpiece. The suction cup in contact with the surface of the workpiece does not allow air to enter from any sides helping in creating the vacuum.

Figure 2: Operating principle of vacuum suction cup: holding force (A), vacuum suction cup (B), workpiece (C).

As the difference between the pressure inside the cup and the atmospheric pressure increases, the holding force of the suction cup also increases. The vacuum suction cup force calculation can be done using the following formula:

Where,

- F = holding force

- ∆P = difference between atmospheric pressure and pressure inside the suction cup

- A = effective suction area

The above formula also shows that the holding force is proportional to the effective suction area. The greater the suction area, the more the holding force.

Types of vacuum suction cups

Depending upon the type of the vacuum suction cup, the following types of vacuum suctions cups are generally available:

Flat vacuum suction cups

For workpieces with a flat or slightly curved surface, flat suction cups are preferred. They are recommended for universal use and provide good stability due to its flat shape. The flat shape makes it suitable to use as vacuum suction cups for glass, metal, and cardboards. They are also suitable for handling heavy metal objects.

Figure 3: Flat vacuum suction cups

Oval vacuum suction cups

They are preferred for handling narrow and elongated surfaces and workpieces (e.g. long metal sheets). They can have bellows or flat surfaces and are generally used when maximum holding force is required.

Figure 4: Oval vacuum suction cup

Bellows vacuum suction cups

Bellow suction cups are used for workpieces with uneven surfaces or varying heights. These suction cups are suitable for handling fragile workpieces like electronic components, injection molded parts, etc. The suction cups with multiple bellows are suitable for handling food packaged and shrink-wrapped products.

Figure 5: Bellows vacuum suction cups

Lip feature

The lip feature in the flat vacuum suction cup prevents leakage and ensures reliable sealing in smooth as well as slightly rough surfaces. They are also available with double safety lip, ultra-thin lip, and robust lip features. The double safety lip vacuum feature prevents separation in case there is leakage through the external lip.

Figure 6: Vacuum suction cups with lips

Supporting ribs feature

The support ribs feature for flat vacuum suction cups helps to increase the holding force and stability of the suction cups.

Additional components

The components discussed below are essential in supporting the performance of vacuum suction cups.

- Vacuum generators: The vacuum generators assists the vacuum suction cups by providing the required vacuum. The vacuum generator operates either electrically or pneumatically. Pneumatic generators help in achieving short and rapid cycle times. These generators can be integrated directly into the system due to their lightweight and compact design. Electric generators are used when high suction capacity is required or when there is no availability of compressed air.

- Compressed air: The vacuum generator uses compressed air to generate a vacuum.

- Hoses: The special vacuum hoses are used with the vacuum suction cups to match the size of the cups and the volume of flow required.

- Fittings: Fittings like ejectors, silencer, vacuum filters, vacuum regulators, generally accompany vacuum suction cups to assist in enhanced performance.

- Valves: Valves like ball valves or solenoid valves support the vacuum suction cups by controlling the vacuum and the flow of compressed air.

Selection criteria

The following selection criteria should be considered for selecting the vacuum suction cup for your application.

- Holding force: The holding force of the vacuum suction cup should never exceed the theoretical holding force. The theoretical holding force is calculated as: F = ∆P x A as mentioned above.

- Safety factor: Depending upon the condition of the surface of the workpiece, the safety factor must be adjusted to the holding force. For smooth or dense workpiece surface, a safety factor of 1.5 and for porous, rough, heterogenous, or oiled surface, a safety factor of 2.0 or more must be adjusted.

- Material: The vacuum suction cups are made up of a wide range of materials. Common materials include silicone, NBR, PUR, and CR. The choice of the material varies depending upon the application. Some materials can be used with smooth or uneven surfaces of wood, glass, and plastics while others for fragile applications such as electronics or packaging.

- Surface: The surface of the workpiece makes a certain type of vacuum suction cups and the material of cups more suitable than others. A flat vacuum suction cup is suitable for flat and slightly curved surfaces while bellows vacuum cups are suitable for uneven surfaces.

-

Coefficient of friction: The coefficient of friction provides information about how well the suction cup can grip and seal the surface of the workpiece. It shows the relationship between the frictional force and the normal force. Several manufacturers use the following generally used values of friction coefficient for various types of workpiece surfaces:

- Oily surface = 0.1

- Moist or wet surface = 0.2 – 0.4

- Rough surface = 0.6

- Glass, stone, and dry plastic = 0.5

- Wood and metal = 0.5

- Sandpaper = 1.1

- The surface of the workpiece, type, and material of the suction cup influences the friction properties. Therefore, it is preferable to determine this friction coefficient through extensive testing in the operating environment.

Vacuum suction cup diameter

The holding force is directly proportional to the effective diameter of the suction cup. To determine the diameter, you need to know how the workpiece will be lifted. Please refer to the next section on how to determine the diameter:

Horizontal suction pad, applying vertical force to lift the workpiece:

To calculate holding force use this formula:

The corresponding diameter can be calculated as:

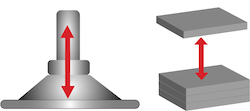

Figure 7: Horizontal suction pad, applying vertical force to lift the workpiece

Where,

- F: Holding force

- m: Weight of the workpiece (kg)

- g: Acceleration due to gravity

- a: Acceleration of the system

- S: Safety factor

- d: Effective diameter

- P0: Vacuum (bar)

- n: Number of suction cups

For horizontal suction pad, moving the workpiece horizontally (to the side):

To calculate holding force use this formula:

The corresponding diameter can be calculated as:

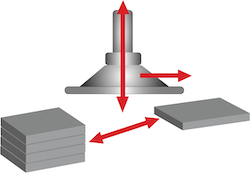

Figure 8: Horizontal suction pad, moving the workpiece horizontally

Where,

- F: Holding force

- m: Weight of the workpiece (kg)

- g: Acceleration due to gravity

- a: Acceleration of the system

- S: Safety factor

- µ: Coefficient of friction

- d: Effective diameter

- P0: Vacuum (bar)

- n: Number of suction cups

For vertical suction pad, applying vertical force to the workpiece:

To calculate holding force use this formula:

The corresponding diameter can be calculated as:

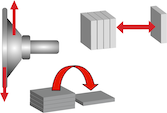

Figure 9: Vertical suction pad, applying vertical force to the workpiece

Where,

- F: Holding force

- m: Weight of the workpiece (kg)

- g: Acceleration due to gravity

- a: Acceleration of the system

- S: Safety factor

- µ: Coefficient of friction

- d: Effective diameter

- P0: Vacuum (bar)

- n: Number of suction cups

Applications

The vacuum suction cups are typically used in the following types of applications:

- Used in manufacturing and automotive industries as lifting vacuum suction cups to handle sheet metals, injection molded parts, car body panels.

- Used as lifting vacuum suction cups for glass panes, floor tiles, windscreens for cars, etc.

- Used in packaging industries to handle cardboard boxes, plastic films, etc.

- Used in food and pharmaceutical industries.

Learn more about different applications of vacuum components in our vacuum ball valves article.