Water Gate Valve - A Guide

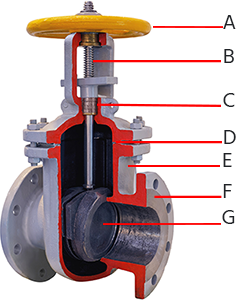

Figure 1: Gate valve

Water gate valves are suitable for regulating water flow in commercial and residential water systems. Due to the diversity of gate valve designs and applicable materials, gate valves can operate well in a wide range of water applications, including plumbing systems. This article will take a closer look at gate valves and offer advice on how to use them effectively in water systems. For a more comprehensive gate valve understanding, read our article on gate valves!

Table of contents

- Water gate valves operating principle

- Types of water gate valves

- Water gate valve materials

- Advantages and disadvantages

- Gate valve water applications

- Other valves for water applications

- FAQs

View our online selection of gate valves!

Water gate valves operating principle

Water gate valves are multi-turn valves that control the flow of water. The valve’s handwheel (Figure 2 labeled A) needs to turn more than 360° for the valve to fully open or close. When opening, stop turning the handwheel when there is resistance. If there is too much resistance, loosen the packing nut. Be sure to tighten it again before operating the valve.

The handle turns clockwise to close the valve. Applying a lot of pressure in an attempt to tighten the seal may cause permanent damage to the valve. If debris accumulates in the valve body, it may not close completely. In this case, open a faucet within the building and work the handle (open and close) to flush out debris and close the water main gate valve. Read our article on troubleshooting and repairing gate valves to learn more.

The stem (Figure 2 labeled B) can be rising or non-rising, meaning it rises out of the valve body when the valve opens or it doesn’t. Also, gate valves are capable of pneumatic, hydraulic, and electric actuation.

When the gate valve is open, water can flow through the valve unimpeded with almost no pressure drop. As the valve closes, its gate (Figure 2 labeled G) slides into the water flow until it completely blocks it. A gate valve is unsuitable for modulating or throttling flow; a partially open or closed valve causes turbidity, which significantly wears down the valve.

The valve body (Figure 2 labeled E) and bonnet (Figure 2 labeled D) protect the inner mechanisms from outside elements and help prevent leaking. The gasket (Figure 2 labeled C) protects the packing and helps stop leaking along the stem. A gate valve’s flanges (Figure 2 labeled F) connect to the piping. Overall, this standard design helps gate valves seal tight and stay leak-free when used in water applications.

Figure 2: Gate valve components: handwheel (A), stem (B), gasket (C), bonnet (D), valve body (E), flange (F), and gate (G).

Water gate valve materials

The following is not a complete list of gate valve body and seal materials. When considering between materials, consult our chemical resistance guide to learn more. Common water gate valve materials for different applications are:

-

Residential and commercial applications: Residential and commercial water systems typically use PVC, CPVC, ABS, brass, or bronze valves because these are cheaper options. The plastic valves, specifically, do not corrode. These materials hold up under most if not all temperature and pressure conditions in a residential water system.

-

Valve body

- PVC: Working temperature 0 - 60 °C (140 °F); Schedule 80 PVC handles higher pressures and is suitable for residential applications

- CPVC: Working temperature up to 92 °C (198 °F); lead-free so suitable for potable water systems

- ABS: Working temperature -20-80 °C (-4 to 176 °F); working pressure up to 15 bar (217 psi).

- Brass and Bronze: The working temperatures and pressures of brass and bronze valves are controlled by the seal material. Brass is more cost-effective upfront, but is also more susceptible to corrosion, specifically dezincification, if there is more than 15% zinc in the brass.

- Stainless steel: Stainless steel stands out among the above materials because it is not cost-effective upfront. However, stainless steel is highly resistant to corrosion and can operate in a wide range of temperatures and pressures. Also, stainless steel has a life expectancy of up to 50 years.

-

Valve seal

- Metal-to-metal: Metal-to-metal seals withstand higher temperatures but also have higher leakage rates and are less suitable for residential and commercial applications.

- Non-metal: EPDM, NBR, and FKM seals are all suitable for residential and commercial applications. The lowest maximum working temperature among these materials (shared by EPDM and NBR) is 120 °C (248 °F).

-

Valve body

-

Industrial applications: Industrial valves typically require higher temperature, pressure, and chemical resistance than valves used in residential and commercial water systems.

-

Valve body

- Cast iron: Some cast iron has a working temperature up to 1150 °C (2100 °F); working pressure depends on the pressure class, the two most common being class 125 and class 250, rated for 13 bar 9188 psi) and 34 bar (493 psi) respectively at less extreme temperatures.

- Ductile iron: Working temperature up to 730 °C; pressure classes 150 and 300, rated for 17 bar (246 psi) and 44 bar (638 psi) respectively.

- Forged steel: Working temperature from -29 °C (-20.2 °F) to 425 °C (797 °F); a class 800 forged steel valve has working pressure up to 138 bar (2001 psi).

-

Valve seal

- PTFE: PTFE (Teflon) seals have a working temperature up to 260 °C (500 °F). Applications with temperatures above this require metal-to-metal seals.

-

Valve body

-

Rust and corrosion resistance

- Rust and corrosion can cause health issues and damage to plumbing.

- Plastic valves do not corrode or rust.

- Stainless steel and bronze have corrosion resistance, but certain acids and chemicals can corrode these materials.

- Bronze: formic acid vapor, sodium chloride, or sulfur dioxide

- Stainless steel: Stainless steel valves can corrode when exposed to the following for a long period of time: damaging chemicals, heat, moisture, saline, or grease.

Advantages and disadvantages

Advantages

- Water gate valves are versatile and have several uses.

- Durability and reliability

- Ease of operation

- Available in a variety of sizes and designs

- Insignificant pressure drop across the valve

- Bidirectional

- Suitable for high-pressure and temperature applications

Disadvantages

- Prone to leaking if not maintained properly

- Cannot be used for throttling

- Very noisy when partially open or closed

Gate valve water applications

- Water main gate valve: Gate valves are the most common type of valve used for opening and closing water flow in a water main. Primarily, water main gate valves are used to isolate parts of the system for maintenance.

- Irrigation systems: Gate valves permit large volumes of water and are ideal for irrigation systems. They are the primary shut-off valve between the irrigation system and the water supply. They can also isolate flows within the system.

- Water distribution systems: A gate valve used in a water distribution system is also referred to as a water service valve. Because these valves are typically in underground piping systems, a non-rising stem gate valve is the typical type used. The valve’s primary function in this system is to isolate flows.

- Industrial water systems: Industrial water is water used in a wide range of industries for purposes such as washing, diluting, and transporting. This water typically contains more suspended solids, making gate valves ideal due to their full-bore design.

- Residential and commercial plumbing systems: Gate valves close the main water supply in residential and commercial plumbing. They are also shut-off valves on main and branch water supplies.

- Wastewater treatment plants: Gate valves are shut-off valves in wastewater treatment applications. Knife gate valves are especially applicable due to their disc’s knife-like edge, which can cut through slurries and other solids in media.

Other valves for water applications

Beyond gate valves, there are several types of valves used for water applications. Each type has specific functionality to consider when designing a water system.

- Check valve: There are several types of check valves, including ball, butterfly, and disc check valves. Check valves allow fluid flow in only one direction, preventing backflow.

- Butterfly valve:Butterfly valves are cost-effective at large sizes and take up less space than other valve types. These valves are commonly used in irrigation systems.

- Globe valve: Globe valves are similar to gate valves in that they are multi-turn valves. However, globe valves permit flow modulation and therefore are suitable for precise flow control needs. Read our globe valve vs gate valve article to learn more about their similarities and differences.

- Pressure relief valve: Pressure relief valves open when pressure in a water system rises above a set limit. Boiler systems use pressure relief valves to prevent damage to the overall system.

- Ball valve:Ball valves have replaced gate valves in many applications. Ball valves typically have better sealing properties and are easier to close. The primary disadvantage of ball valves is that they are more expensive than gate valves.

FAQs

What is a water gate valve?

A gate valve used in water applications has excellent sealing properties and is relatively inexpensive compared to many valve types.

How do you open a gate valve?

The proper way to open a gate valve is to turn the handle to the left until you feel resistance. It takes about six turns to open a water gate valve fully.

Can water gate valves be used for throttling?

Gate valves cannot throttle water. There is no close relationship between the size of the opening left by a partially closed disc and the amount of water that flows through the valve.

How do you tell whether a water gate valve is open or closed?

Rising stem gate valves indicate whether they are open or closed based on the height of the handle. Non-rising stem gate valves have a position indicator that shows the position of the gate.