Coaxial Solenoid Valve

Figure 1: A 2/2-way coaxial solenoid valve

A coaxial solenoid valve is a direct-acting valve designed with an unobstructed flow path, making it ideal for high-pressure applications and handling highly viscous media. It is particularly suitable for systems that require high flow rates with minimal pressure loss. These valves are essential for managing dense fluids, such as heavy oils, grease, and syrups, which standard solenoid valves cannot effectively handle. This article explores the features, design, and applications of 2/2-way coaxial solenoid valves.

Table of contents

View our online selection of coaxial solenoid valves!

Coaxial solenoid valve features

- High flow rates and ideal for viscous fluids: Coaxial valves feature an unobstructed flow path, making them suitable for highly viscous liquids (up to 500 centistokes) and allowing for high flow rates with minimal pressure loss.

- High pressure: They can withstand pressures up to 64 bars (232 psi) and back pressures up to 16 bar (232 psi). They are suitable for zero pressure differential and vacuum applications.

- Fast response time: Coaxial valves offer rapid response times (<200 ms) compared to other valves like motorized ball, gate, butterfly, and globe valves.

- Low maintenance: These valves are durable, have a long cycle life, and require minimal maintenance.

- Media compatibility: The coaxial solenoid valves can handle slightly contaminated and abrasive media.

Specifications

- Materials: Coaxial solenoid valves are available in brass or stainless steel. The brass housing suits water, air, oil, or other neutral liquid media. The stainless steel housing is ideal for aggressive and corrosive media. Read our chemical compatibility chart for more information on the compatibility of different materials with various media.

- Kv value: Coaxial solenoid valves have high flow rates and have Kv values up to 11.3 m3/h.

-

Connection size: Ensure the valve connection size matches the existing pipe size to ensure a proper fit and avoid the need for additional adapters.

- Brass coaxial solenoid valves are available from ⅜ - 1 inch. Stainless steel valves are available from ⅜ - ¾ inches.

- Voltage type: Both AC (24V, 120V, 230V) and DC (12V, 24V) coaxial solenoid valves are available

- Connection type: The valves are available in NPT or BSP threads.

Design and operation

The term "coaxial" refers to having a common axis. In contrast to conventional solenoid valves, the plunger movement and electric coil align with the pipe.

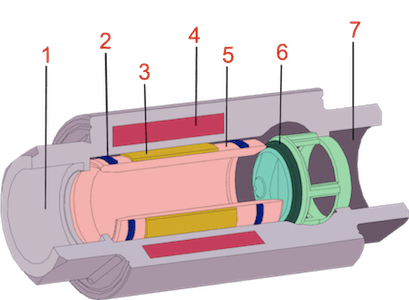

In a 2/2-way coaxial solenoid valve, the solenoid is installed concentrically around an internal, laterally movable tube (Figure 2 labeled E) through which the fluid flows. This internal tube is directly connected to a magnetic plunger (Figure 2 labeled C), which moves parallel to the flow direction when the coil (Figure 2 labeled D) is energized. This lateral movement changes the valve's state to either open or closed, regardless of system pressure.

In a normally closed valve, energizing the coil causes the tube to move against a return spring (not shown in Figure 2) and away from the valve seat (Figure 2 labeled F), allowing fluid to flow. When the coil is de-energized, the return spring pushes the tube back to the valve seat, stopping the flow. O-rings (Figure 2 labeled B) seal and secure the tube to prevent the media from contacting other internal parts of the valve.

Figure 2: A sectional view of a 2/2-way coaxial solenoid valve when open. Components: valve inlet (A), o-ring seal (B), plunger (C), coil (D), tube (E), valve seat (F), & outlet (G)

Applications

Coaxial valves are highly effective for handling lubricants in mechanical and plant engineering fields. They are well-suited for use in ship and rail engines, test bench construction, vacuum and gas technology, and systems for filling and dosing. These valves can manage both liquid and gaseous media, even if they are dirty or gelatinous, such as coolants, oils, syrups, thick hydrocarbons, emulsions, and lubricants, as long as the correct seals are applied.

Disadvantages

- Coaxial solenoid valves have a high power rating, which can cause the coil to become hot. Installing them in a well-ventilated environment is recommended to help dissipate the heat.

- The coaxial solenoid valve weighs approximately 3.45 kg (7.6 lb) for the brass version and 5.3 kg (11.7 lb) for the stainless steel version, which is relatively heavy.

- The coil cannot be replaced separately as it is integrated into the valve body.