NP – National (American) Pipe Thread

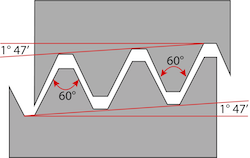

Figure 1: NPT thread

The NP (National pipe) thread standard is used in Canada and the United States. They have tapered threads, which offer a more powerful seal than straight threads and are used in hydraulic, plumbing, and gas transportation applications. These threads were originally made from materials like brass and steel, but nowadays, they are also made with materials such as PVC, bronze, and cast iron.

Table of contents

- What is the NP thread standard?

- How NPT threads work

- Labeling examples

- Reusing NPT threaded pipes and fittings

- NPT vs NPS

- NPT vs NPTF

- FAQs

Explore Tameson's selection of thread cutting tools

What is the NP thread standard?

The American national pipe thread was created based on a 60° V-thread with flattened peaks and valleys (Figure 1). There are two types of NP threads:

- NPS: Straight threads, meaning the male and female threads have a constant major diameter or minor diameter across the thread’s length.

- NPT: The male and female threads are tapered. NPT threads are more commonly used. NPT Thread specifications are based on ANSI B1.20.1 and the thread sizes can be seen in Table 4. Read our thread identification article for more information on how to identify an unknown thread type.

Figure 1: NPT thread profile: the top is an internal thread and the bottom is an external thread.

How NPT threads work

NPT pipe threads use tapered threads to ensure a strong connection. The tapered thread wedges the male and female thread flanks together during tightening. This wedging creates an elastic compression between the threads (thread deformation) when installed correctly. The thread’s elastic thread deformation creates a spring tension that binds the threads tightly together. The thread deformation, along with friction (interference fit) between the flank surfaces, locks the threads together in a well-built, tight connection that does not vibrate loose.

Theoretically, NPT threads do not need a thread sealant because they are tapered. However, NPT pipe thread design favors mild clearance between the thread crests and mating roots. This clearance generates a spiral leak path along the crests of the male threads. Due to the spiral leak path, NPT connections require a thread sealant like Teflon tape or pipe dope to be leak proof.

There are several variations of the NPT thread to overcome the issue of spiral leakage. The most popular among them is the NPTF (F for fuel). With NPTF thread design, there are regulations on the roots and crests of the male and the female threads to verify that the crest displaces the material into the mating thread’s root. The interference fit between the crest of one thread and the root of the other, along with the matching thread flanks, seals against spiral leakage.

Table 1: NPT – National (American) Pipe Thread Tapered

| Nominal Thread Size (inch) | Major diameter (mm) | Major diameter (inch) | TPI (in-1) |

| 1/16 | 7.950 | 0.31 | 27 |

| 1/8 | 10.287 | 0.405 | 27 |

| 1/4 | 13.716 | 0.54 | 18 |

| 3/8 | 17.145 | 0.675 | 18 |

| 1/2 | 21.336 | 0.84 | 14 |

| 3/4 | 26.670 | 1.05 | 14 |

| 1 | 33.401 | 1.315 | 11.5 |

| 2 | 60.325 | 2.375 | 11.5 |

Table 2: NPS dimensions

|

Pipe Size (inches) |

TPI |

Pipe diameter (inches) |

Pipe diameter (mm) |

Female Thread Inside Diameter (inches) |

Female Thread Inside Diameter (mm) |

| 1/8 | 27 | 0.405 | 10.3 | 0.34 | 8.636 |

| 1/4 | 18 | 0.540 | 13.7 | 0.47 | 11.94 |

| 3/8 | 18 | 0.675 | 17.1 | 0.59 | 14.98 |

| 1/2 | 14 | 0.840 | 21.33 | 0.75 | 19.05 |

| 3/4 | 14 | 1.050 | 26.67 | 0.97 | 24.638 |

| 1 | 11.5 | 1.315 | 33.4 | 1.20 | 30.48 |

| 1 1/4 | 11.5 | 1.660 | 42.1 | 1.55 | 39.37 |

| 1 1/2 | 11.5 | 1.900 | 48.3 | 1.79 | 45.46 |

| 2 | 11.5 | 2.375 | 60.325 | 2.26 | 57.4 |

| 2 1/2 | 8 | 2.875 | 73.025 | 2.71 | 68.83 |

| 3 | 8 | 3.500 | 88.9 | 3.33 | 84.58 |

| 3 1/2 | 8 | 4.000 | 101.6 | ||

| 4 | 8 | 4.500 | 114.3 | ||

| 4 1/2 | 8 | 5.000 | 127 | ||

| 5 | 8 | 5.563 | 141.3 | ||

| 6 | 8 | 6.625 | 168.275 |

Labeling examples

National pipe threads are designated with their nominal size, followed by the number of threads per inch and the symbol for the thread series (NPT, NPS, etc.).

- 3/8 - 18 NPT: NPT thread series with ⅜ inch nominal size and 18 threads per inch

- 1/8 - 27 NPS: NPS thread series with⅛ inch nominal size and 27 threads per inch

Reusing NPT threaded pipes and fittings

Thoroughly examine NPT fitting threads before reusing them. There is a possibility of permanent thread deformation caused by over tightening during installation. Therefore, reusing NPT threads is generally not recommended. NPT threads can also be damaged from continuous assembly and disassembly. A general rule of thumb is to replace male threaded fittings after two or three uses. However, it may be practical to reuse a fitting and ensure a leak proof connection if:

- No more than the usual amount of thread sealant is required to make a good seal. No more than six threads from the male connection end go into the female port for a good fit.

- The threads are not overtightened during installation.

NPT vs NPS

NPT and NPS thread standards have the same flank angle, shape, and TPI (threads per inch). But, NPT threads are tapered, while NPS threads tend to be parallel or straight. Pipe fittings and ends (i.e., tees, couplings, elbows, etc.) commonly use tapered pipe threads. Tapered threads are paramount for joints to be leak tight. A tape or thread sealant is typically required to complete the seal. Parallel pipe threads need an o-ring or gasket to create a tight seal.

Note: NPT and NPS threads will engage with each other, but they do not seal properly.

NPT vs NPTF

ANSI B1.20.1 gives the requirements for NPT, and ANSI B1.20.3 provides the criteria for NPTF. NPT and NPTF have the same pitch diameters, threads-per-inch, and taper-per-inch. The differences between both standards arise from parameters like the major and minor diameters, the crest, and the root of the threads. The NPTF thread crests fall under the parameters of the requirements laid by the NPT standard, but they have a comparatively smaller range than the NPT standard. Also, the thread roots of NPTF are different from that of NPT. The NPTF thread roots are designed to interfere with the mating thread’s crest to make a strong seal during assembly.

Read our BSP, Unified thread standard, and M-Metric thread articles for more details on other thread standard types.

FAQs

What is the NP thread standard?

The NP (National pipe) thread standard is used in the United States and Canada. The standard was created based on a 60° V-thread with flattened peaks and valleys.