How to Identify an Unknown Thread Type

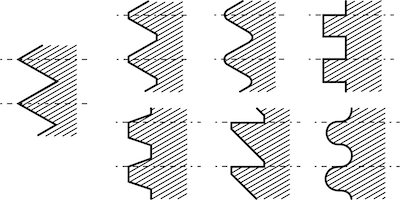

Figure 1: Several thread standard profiles

If two threaded components are not connecting properly, it may be from unmatched threads making it important to know how to identify which thread standards each component is using. Several thread standards exist worldwide, such as the UTS (Unified Thread Standard) and the ISO Metric Thread Standard, for screws and other threaded fasteners. Some thread types, such as trapezoidal thread, are easier to identify visually. However, many thread types have a similar V- or rounded-thread shape. Despite their similar appearance, they are different and cannot properly connect. This article describes avoiding mismatched threads by identifying unknown thread types. Read our article on thread design to learn more.

Explore Tameson's selection of thread cutting tools

Parameters for identifying a thread

There are four factors to determine when identifying a thread:

- External or internal threads

- Straight or tapered threads

- Thread nominal diameter

- Thread pitch

External vs internal thread

External threads are male threads, and internal threads are female threads. To identify a thread type, measure the major diameter:

- External thread major diameter: The major diameter is measured from crest to crest (high point to high point) across the thread axis, an imaginary line running through the center of the thread.

- Internal thread major diameter: The major diameter is measured from root to root (low point to low point) across the thread axis.

Figure 2: Thread dimensions: pitch (A), flank angle (B), minor diameter (C), pitch diameter (D), major diameter (E), depth (F), crest (G), and groove (H)

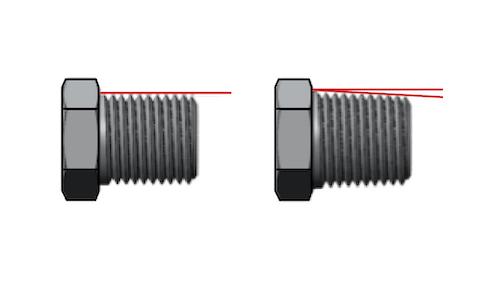

Straight thread vs tapered thread

A straight thread has a constant nominal diameter across its length, whereas a tapered thread does not. Measure the nominal diameter of a straight thread at any point. For a tapered thread, measure the nominal diameter at the 4th or 5th thread from the head to get the true measurement.

Figure 3: A straight male thread with constant major diameter (left) and a tapered male thread with varying major diameter (right)

Nominal diameter and pitch

As discussed above, the nominal diameter of an external thread is the distance from crest-to-crest across the thread axis. And the nominal diameter of internal threads is the distance from root-to-root across the thread axis. To precisely measure the diameter of any thread, use a Vernier caliper.

A thread’s pitch is the distance between two consecutive crests. The metric thread standard uses this measurement in its designation. For example, M10 x 1.25. 1.25 is the pitch in millimeters. UTS threads use TPI (thread-per-inch) in their designation, which is the inverse of pitch. For example, #6 - 32 UNC. The 32 is the thread-per-inch. Read our guide on how to measure thread size to learn more.

Thread standards

After identifying a thread’s parameters, look in thread standard charts to compare the thread’s nominal diameter and pitch. Start by checking our thread standards overview article and individual thread standard articles:

Example

An external screw thread with approximately 0.5 mm pitch and 3.0 mm major diameter. This example shows why a precise caliper is necessary when identifying a thread. Some metric threads are very similar to UTS threads. A M3 x 0.5 thread has a 2.980 mm major diameter and 0.5 mm pitch. A unified fine thread has a 0.53 mm pitch and a 2.84 mm major diameter. In this example, the major diameter is very close to 3.0 mm. Therefore, the screw thread is metric and not UTS.

Read our thread compatibility article for more information on the compatibility between various thread types.

FAQs

How to identify unknown threads

Use a caliper and pitch gauge to determine a thread's nominal diameter and pitch easily. Then compare the results to thread standard charts.

What is the most common thread type?

The Unified Thread Standard (UTS) screw thread and ISO Metric Screw Thread are the most common thread types.