Thread Design

Figure 1: Long threaded bolts.

Threads are frequently used to connect pipes and fittings. These threaded connections come in various designs and can fit different sizes and shapes. They are leak-resistant and offer mechanical support against gravity. Check out our tap and die set article to learn how to create custom threads.

Thread design specifications

A thread is a wedge wrapped around a cylindrical or conical shape, providing a joint by mating to another thread. Threads have numerous sizes and shape designs to serve various purposes. Ensuring thread compatibility and a proper seal is important for achieving a reliable joint. Threads are identified by their design characteristics. When selecting a product with threads, it is important to understand a few thread specifications:

- Male and female threads

- Right-handed and left-handed threads

- Taper

- Diameter

- Angle

- Pitch and threads per inch (TPI)

- Starts

- Form

Explore Tameson's selection of thread cutting tools

Male and female threads

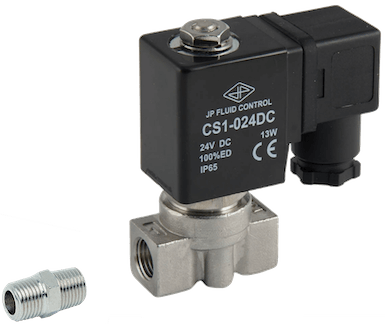

All matching thread connections consist of a male (external) and a female (internal) thread type. In a given connection, threads must have the same design characteristics to ensure adequate leakproof tightness and/or mechanical performance. Generally, threaded port connections of valves are female, as seen in Figure 2 on the right.

Figure 2: Internal vs external thread: A hexagon nipple fitting (left) and a solenoid valve (right)

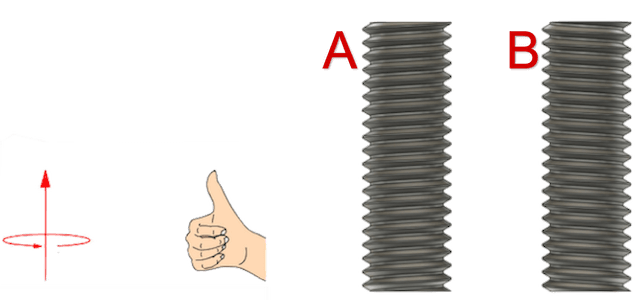

Right-handed and left-handed threads

A thread's helix (or spiral) part can be either right-handed or left-handed. Most threads are right-handed and follow the right-hand grip rule. This rule states that when a thread is engaged in a connection, it moves upward when rotated towards the right hand. The letters ‘LH’ in a thread specification stand for a left-handed thread which is rotated in the direction of the left hand to move the thread up. Figure 3 shows the differences along with the right-hand rule.

Figure 2: Handedness in threads: right-handed (A) and left-handed (B)

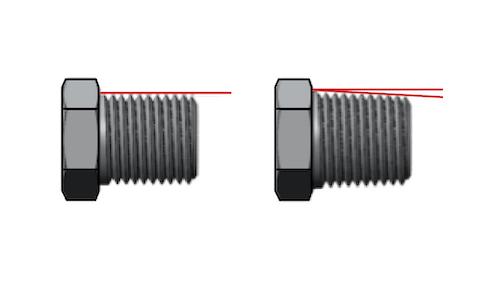

Taper

The helix of a thread wraps around a conical or cylindrical rod. A thread on a conical rod, as seen on the left of Figure 4, creates a tapered thread. A thread on a cylindrical shape, as seen on the right of Figure 4, creates a straight or parallel thread. The taper angle is the angle between the conical shape and the centerline of the pipe.

A tapered thread connection creates leak-tightness by the male and female threads compressing and deforming into each other. On the other hand, straight threads do not create a leak-tight joint on the threads and are often sealed with o-rings or gaskets.

Figure 4: A straight male thread with constant major diameter (left) and a tapered male thread with varying major diameter (right)

Diameter

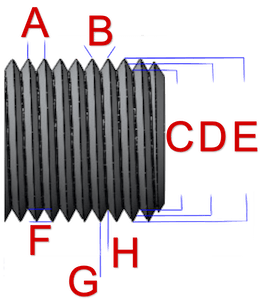

A thread's major diameter (Figure 5 labeled E) is the larger of the thread profile’s two extreme diameters. For external threads, the major diameter is the crest-to-crest diameter across the thread’s axis. For internal threads, the major diameter is root to root. For both types of threads, the minor diameter (Figure 5 labeled C) is the opposite: external, root to root, and internal, crest to crest. The depth of a thread (Figure 5 labeled F) is the difference between the major and minor diameters. The pitch diameter (Figure 5 labeled D) is measured from a line that intersects the flanks of a thread and is halfway between the major and minor diameters.

Figure 5: Thread dimensions: pitch (A), flank angle (B), minor diameter (C), pitch diameter (D), major diameter (E), depth (F), crest (G), and groove (H)

Angle

The thread angle, or flank angle, (Figure 5 labeled B) is the angle between thread flanks. The most commonly used thread angles are 60° and 55°.

Pitch and threads per inch (TPI)

The pitch (Figure 5 labeled A) is the distance between crests of two consecutive threads. Threads per inch (TPI) is the reciprocal of the pitch. For example, a thread with a TPI of 12 has a pitch size of an inch. While TPI describes imperial threads, the pitch is often used for metric threads and is given in mm.

Starts

The number of starts of a thread determines the number of ridges wrapped around it to create the thread. The number of starts determines the number of threads a screw moves when turned 360°. One-start threads are the most common pipe thread. Figure 6 is color-coded to show the difference in ridge numbers per start.

Figure 6: Number of starts in a thread from one to four from left to right.

Form

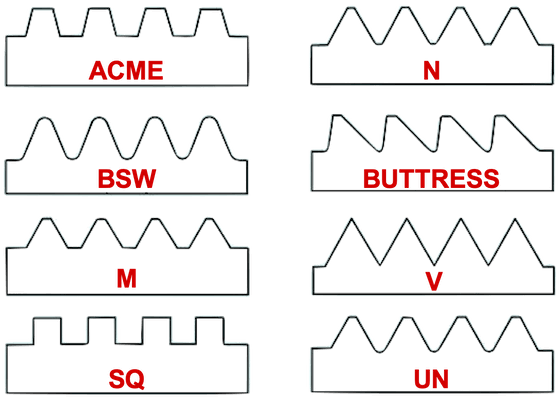

The cross-section of a thread is called its form. Threads can be triangular, square, trapezoidal, or other shapes (Figure 7). The triangular-shaped threads are also called V-threads. Although V-threads are represented as triangular, in practice, the tip and groove of the thread cannot have a perfectly sharp edge and are therefore truncated (cut short) at varying degrees. A sharp V-thread is a thread where the tips of the triangles are not truncated.

Figure 7: Types of threads: ACME, National Thread (N), British Standard Whitworth (BSW), BUTTRESS, Metric (M), Sharp V (V), Square (SQ), and Unified National (UN).

Sealing a threaded connection

When connecting two threads, it is essential to consider the hydraulic seal they will create. Parallel and tapered threads can be combined to create two types of connections: jointing threads and longscrew (fastening) threads.

Jointing threads

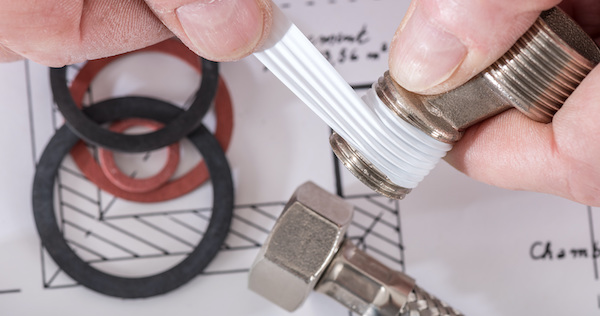

Figure 8: Thread seal tape used for better sealing of jointing threads.

Ajointing thread connection creates pressure-tightness by compressing the threads together. For this, tapered male threads are coupled with parallel or tapered female threads. In this type of joint, a positive seal is created by deforming the threads into each other through wrench tightening to ensure proper torque. This means that repeated assembly and disassembly can distort the threads. Therefore, it is vital to check this joint type for any leak paths or damage to the threads.

A sealing coating or a jointing compound on the threads, such as thread seal tape or pipe dope, is often used in this type of connection (Figure 8). When using seal tape, only two turns of sealant are required. Please note that an o-ring seal cannot be used with a tapered male thread as it will not allow the threads to be tightened completely. Some precise threads are known as ‘dry fit’ or ‘dry seal’ and do not require any seal material. In these joints, the pressure-tightness is solely created by the compression of threads and is especially used to create a gas-tight seal or when the sealant could contaminate or react with the media (e.g., oxygen).

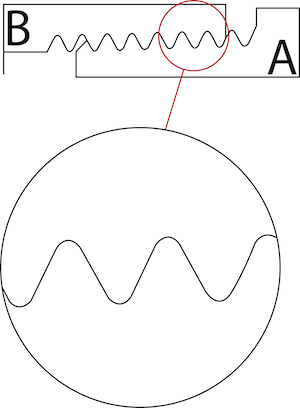

Jointing threads may become susceptible to leakage through tightening and untightening during repair or assembly. When a tapered male thread is tightened to a parallel female thread, the seal is only made at the base of the female port with 1-2 threads due to the difference in taper. This means that the area where the crest of the male and the root of the female threads meet can form a spiral leak path. This is especially the case with BSPT connections. BSPT threads are commonly used for low-pressure applications and are not recommended for medium or high-pressure systems. This problem can be solved if the male and female threads are tapered (e.g., NPT connections).

Figure 9: The male thread on the bottom (A) is BSPT, and the female thread on the top (B) is BSPP

Longscrew or fastening threads

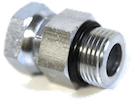

In this type of joint, a reliable seal is created by compression of a soft material (an o-ring seal or a washer) or a flat gasket between the shoulder of the male pipe and the interior surface of the female thread.

Figure 10: O-ring on a male thread