How to Choose the Right Cylindrical Roller Bearings

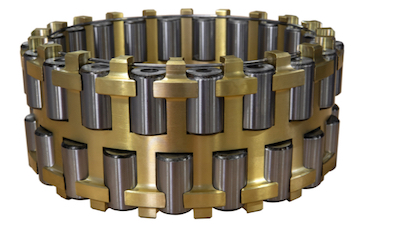

Figure 1: Cylindrical Roller Bearing

Manufacturers design bearings to 'bear' or carry a load while restricting motion and reducing friction between moving parts. Cylindrical roller bearings are one type of bearing designed for high-load, circular needs. Ribs guide these cylindrical rolling elements on the inner or outer rings designed to move freely in the axial direction, making this bearing ideal for applications with thermal expansion on the shaft, like an electric motor.

A better understanding of cylindrical roller bearings, their functions, and their advantages and disadvantages helps select the correct bearing for each application.

Table of contents

- What are cylindrical roller bearings?

- Components and materials

- Why use cylindrical roller bearings?

- Cylindrical roller bearings applications

- FAQs

View our online selection of bearings!

What are cylindrical roller bearings?

A cylindrical roller bearing is a contact-type bearing that is different from other bearings. They use cylinder-shaped rolling parts instead of balls like you'd find in ball bearings. Because cylindrical rollers are in linear contact with the raceways, they have a greater circular load capacity than ball bearings.

Though the rollers are cylindrically-shaped, they are not true cylinders. The rollers are crowned or end-relieved to reduce stress, resulting in low friction. Low friction makes them an ideal choice for high-speed situations. Cylindrical roller bearings are typically lubricated with oil to reduce heat caused by high speeds.

Components and materials

Cylindrical roller bearings are radial-type roller bearings. This class of roller bearing includes tapered, spherical, and needle roller bearings. All cylindrical roller bearings have four essential components: an inner ring, an outer ring, rollers, and a cage. The bearing rings and rollers carry the load, and the cage (Figure 2) keeps the rollers in place.

Cylindrical roller bearings vary from clearance and lubrication options, depending on the manufacturer. They can be made with a cage or as a full complemented part. Some have no ribs on either ring, allowing axial movement of the rings, which can be used as free-end bearings.

Pressed steel or machined brass are the most common materials to form cylindrical roller bearing cages. Still, some use molded polyamide, which makes smoother and quieter running bearings. When necessary, hardened high carbon steel or carburized low carbon steel enhances bending fatigue and handles heavy shock loads.

Figure 2: Double-row cylindrical roller bearing cage and rollers

Single vs multi-row types

Though single row cylindrical roller bearings are the most common type, cylindrical rollers also come in multi-row options.

- Single-row cylindrical rollers are popular because they are separable, making them easier to mount and dismount. However, they do not support heavy or oversized radial loads because they only allow axial loads in one direction.

- Double-row cylindrical roller bearings often solve load capacity challenges. Double-row bearings spread the load over a broader area and handle destabilizing loads or vibrations. In addition, one double-row bearing takes up less space inside the bearing housing than placing two single-row bearings back-to-back. It also optimizes load transfer between the two rows.

- Multi-row, or four-row, cylindrical roller bearings are often used as roll-neck bearings. The four rows of rollers accommodate larger radial loads. Tight diametrical tolerances on contoured rollers allow bearings to distribute loadings evenly. Cages for multi-row rollers commonly use a machined brass finger cage or a mild steel finger cage. Still, larger sizes use a steel pin-type cage with hollow rollers.

Figure 3: Double-row cylindrical roller bearing

Why use cylindrical roller bearings?

With cylindrical roller bearings, the outer load is continuously re-distributed among the rollers. Fewer than half of the total number of rollers carry the application's load as the inner ring rotates. The weight distribution is superior to the load-bearing capacity of ball bearings. It contributes to the service life of the bearing.

Advantages

- Capable of handling higher radial loads when compared to other roller bearings or ball bearings

- Can handle high speeds

- High stiffness

- Can handle both axial and radial loads

- High precision

- Long service life

- Available in single, double, and multi-row configurations to accommodate various load requirements

- Lower friction, temperature, and power consumption

Disadvantages

- Noisier than other bearings

- Higher cost

Cylindrical roller bearing selection criteria

There are several criteria to consider when selecting cylindrical roller bearings. For example, one must consider dimensions, the operational speed and load specifications, unique installation features, and materials' choice. DIN Standards 635-1 outline specific dimensions and symbols for single-row spherical roller bearings, while DIN 635-2 standards refer to double-row configurations.

Dimensions

One must consider three dimensions when selecting bearings for a specific application, including:

- Bore. The bearing industry has a standard number system for radial bearings with metric diameter bores.

- Outside Diameter. Outside diameter is the overall width of the outer ring. Still, housed units include the housing, while flanged units exclude the flange.

- Overall Width. Overall width of the bearing, or bearing assembly, including the locking collar, if present.

Operating specifications

Axial load support in one direction (single-row) or two directions (double-row), and loading parameters, need to be considered when selecting the correct bearing, including:

- Rated speed

- Static axial or thrust load

- Static radial load

- Dynamic axial or thrust load

- Dynamic radial load

Unique features

An application may also require some unique features. In some instances, bearings are flanged for mounting or locating purposes. A spherical outside diameter has a greater load capacity and allows a bearing to be more tolerant of misalignment but requires more radial space.

Materials

Some applications require thoroughly hardened high carbon bearing quality steel, which is more durable than typical alloy or low carbon steel bearings. Further, material processing can add carbon and alloys to low carbon grades of steel. This process produces a fatigue-resistant case and a rigid, malleable core, improving the bending fatigue to accommodate heavy shock loads.

Applications

Their greater radial load capacity and their ability to accommodate faster speeds, as well as other benefits, make cylindrical roller bearings an ideal solution for a variety of industries, including:

- Oil and gas

- Gearboxes

- Wind turbines

- Machine tool

- Electric motors

- Material handling

- Pumps

- Steel mills

FAQs

Do cylindrical roller bearings have low friction?

Yes. The design of the rollers and surface allows cylindrical roller bearings to manage heavy loading with low levels of friction.

What causes cylindrical roller bearings to fail?

Improper mounting and sealing, lubricant failure, and the presence of debris and contaminants are the most common reasons for bearing failure. In addition, excessive loading can lead to overheating and failure.

What maintenance procedures should I follow?

Cylindrical roller bearings, like all bearings, are subjected to rust, pitting, scratches, and chips. Bearings treated with a surface coating helps to extend the life of the bearing by preventing these instances.

What kind of surface treatments should I use on a cylindrical roller bearing?

Zinc-nickel plating, zinc, and phosphate coatings help protect against rust, pitting, scratching, and chipping.

What is the difference between needle bearings and cylindrical roller bearings?

The length/diameter ratio of needle-bearing rollers is greater than four. In contrast, the length of the rollers in a cylindrical roller bearing is shorter with a larger diameter.